Method for preparing sulfur-doped hypoxia type TiO2 photocatalyst

A photocatalyst and sulfur doping technology, applied in the field of photocatalytic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

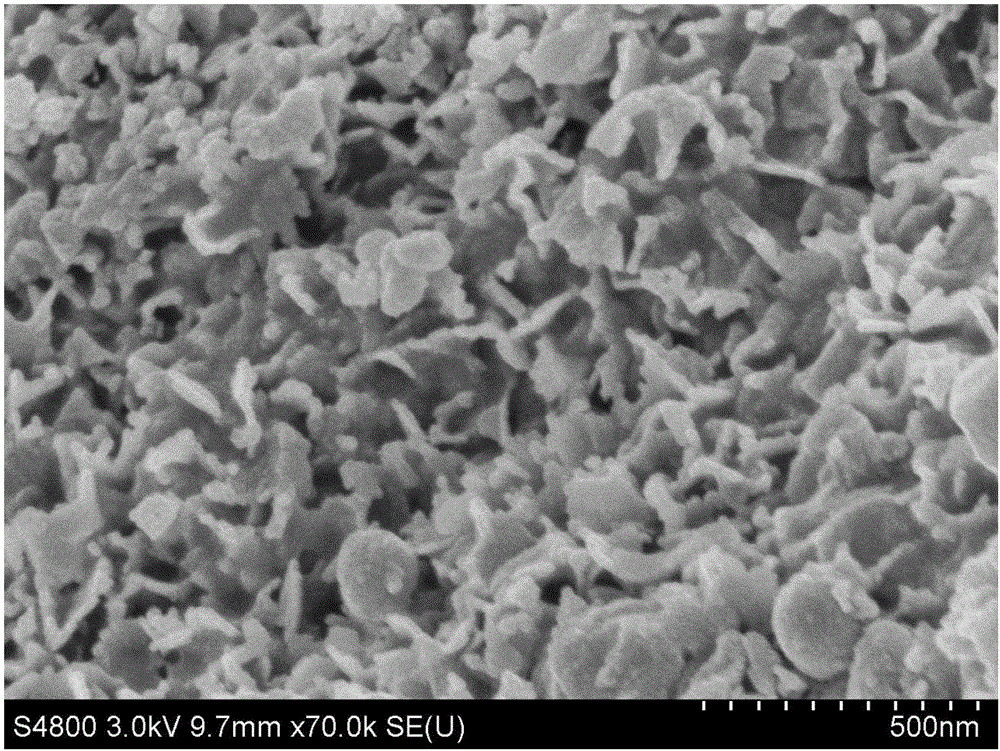

Image

Examples

preparation example Construction

[0034] A kind of sulfur-doped oxygen-deficient TiO 2 The preparation method of photocatalyst comprises the following steps:

[0035] (1) According to the fixed ratio of molar ratio n(Ti):n(Si)=1:2, Ti(SO 4 ) 2 and Na 2 SiO 3 9H 2 The amount of O, and then according to the molar ratio n(TiO 2 ): n(TiS 2 )=1:(0.03~0.1) ratio to determine Na 2 The amount of S and Ti(SO 4 ) 2 Supplementary dosage, thus determined Ti(SO 4 ) 2 total usage. Then based on the total molar amount of Ti and the molar ratio n(Ti):n(SO 4 )=1:(0.02~0.06) to determine the doping (NH 4 ) 2 SO 4 the amount of introduction. Thereafter, the corresponding chemical reagents were weighed, and the Na 2 S, Ti(SO 4 ) 2 and (NH 4 ) 2 SO 4 dissolve into an aqueous solution;

[0036] (2) Na 2 SiO 3 9H 2 O Use deionized water to prepare an aqueous solution with a concentration of 0.60-0.65 mol / L, place it in a digitally controlled temperature-adjusted ultrasonic instrument, and first dissolve Ti(...

Embodiment 1

[0042] (1) According to the fixed ratio of molar ratio n(Ti):n(Si)=1:2, Ti(SO 4 ) 2 and Na 2 SiO 3 9H 2 The amount of O, and then according to the molar ratio n(TiO 2 ): n(TiS 2 ) = 1:0.06 ratio to determine Na 2 The amount of S and Ti(SO 4 ) 2 Supplementary dosage, thus determined Ti(SO 4 ) 2 total usage. Then based on the total molar amount of Ti and the molar ratio n(Ti):n(SO 4 )=1:0.04 to determine doping (NH 4 ) 2 SO 4 the amount of introduction. Thereafter, the corresponding chemical reagents were weighed, and the Na 2 S, Ti(SO 4 ) 2 and (NH 4 ) 2 SO 4 dissolve into an aqueous solution;

[0043] (2) Na 2 SiO 3 9H 2 O Use deionized water to prepare an aqueous solution with a concentration of 0.65 mol / L, place it in a digitally controlled temperature-adjusting ultrasonic instrument, and under the action of continuous stirring and ultrasonic waves at 50°C, Ti(SO 4 ) 2 Add the solution slowly, and continue adding Na slowly after 10 min 2 S solution...

Embodiment 2

[0050] (1) According to the fixed ratio of molar ratio n(Ti):n(Si)=1:2, Ti(SO 4 ) 2 and Na 2 SiO 3 9H 2 The amount of O, and then according to the molar ratio n(TiO 2 ): n(TiS 2 )=1:0.03 ratio to determine Na 2 The amount of S and Ti(SO 4 ) 2 Supplementary dosage, thus determined Ti(SO 4 ) 2 total usage. Then based on the total molar amount of Ti and the molar ratio n(Ti):n(SO 4 )=1:0.06 to determine doping (NH 4 ) 2 SO 4 the amount of introduction. Thereafter, the corresponding chemical reagents were weighed, and the Na 2 S, Ti(SO 4 ) 2 and (NH 4 ) 2 SO 4 dissolve into an aqueous solution;

[0051] (2) Na 2 SiO 3 9H 2 O Use deionized water to prepare an aqueous solution with a concentration of 0.60 mol / L, place it in a digitally controlled temperature-adjusted ultrasonic instrument, and firstly dissolve Ti(SO 4 ) 2 Add the solution slowly, and continue to add Na slowly after 5min 2 S solution. Continue ultrasonic stirring for 25 minutes to form a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com