Porous alumina ceramic supported cu-mof adsorbent and preparation method thereof

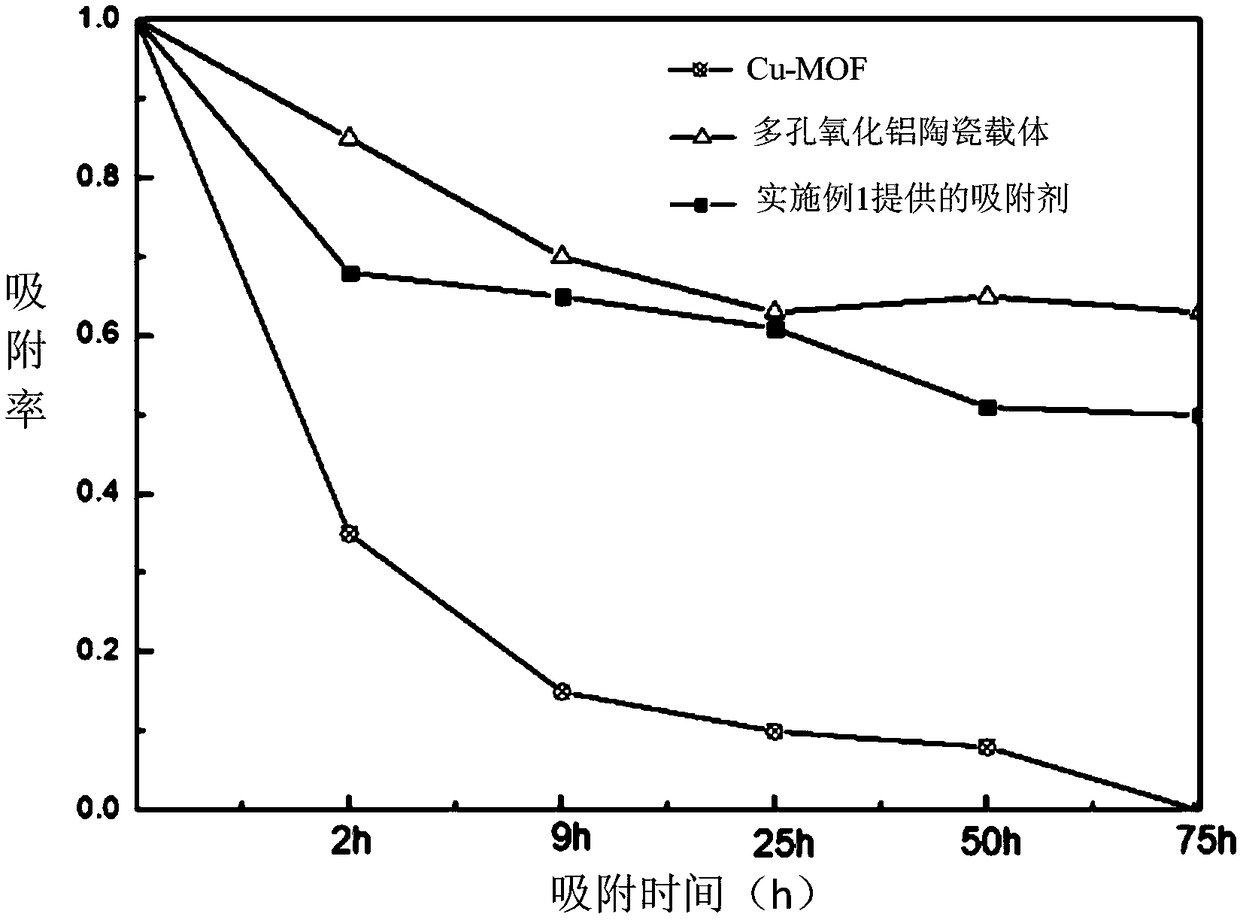

A porous alumina and ceramic loading technology, which is applied in ceramic products, chemical instruments and methods, and other chemical processes, can solve the problem of no loading of MOF materials, achieve the effect of overcoming low strength, high permeability, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for preparing a porous alumina ceramic loaded Cu-MOF adsorbent, which includes the following steps:

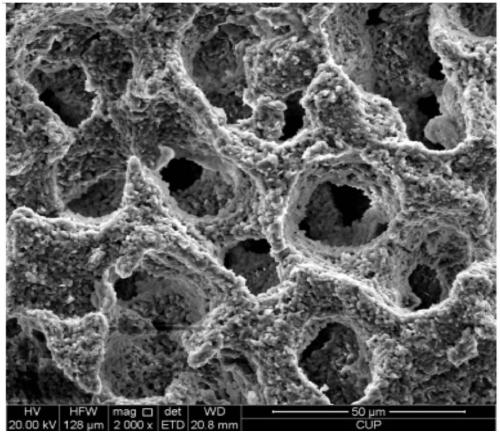

[0047] (1) Preparation of porous alumina ceramic carrier

[0048] Mix 10g of alumina powder, 0.3g of sodium polyacrylamide, 34.6mL of camphene, and 5.19mL of ethanol into a flask and mix and stir in an oil bath at 70°C for 12 hours to obtain a uniformly mixed ceramic slurry;

[0049] Inject the ceramic slurry into the forming mold and let it stand for 1 hour, take it out from the mold after solidification, and obtain the alumina ceramic green body;

[0050] Place the demolded alumina ceramic green body at -16°C for 24h, then put it into a vacuum freeze dryer at -40°C, dry it under reduced pressure at 100μHg for 12h, take it out, and finally dry it at 4°C / min The temperature is raised at a certain speed for high-temperature sintering, and the temperature is raised to 1600 ° C, kept for 3 hours, and the porous alumina ceramic carrier is ...

Embodiment 2

[0062] This embodiment provides a method for preparing a porous alumina ceramic loaded Cu-MOF adsorbent, which includes the following steps:

[0063] (1) The preparation process of the porous alumina ceramic carrier is the same as in Example 1;

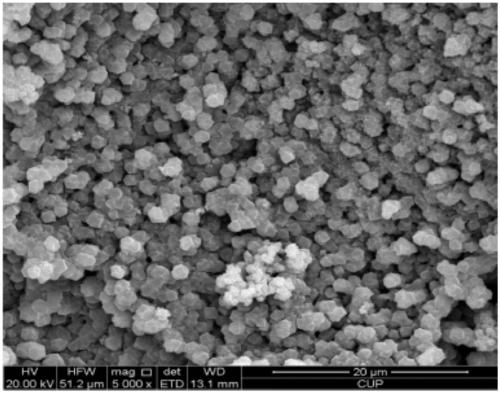

[0064] (2) In situ synthesis of Cu-MOF

[0065] Take 0.84g of trimesic acid, add it to 50mL of ethanol solution with a mass fraction of 95%, and use it as a ligand solution;

[0066] Soak the prepared porous alumina ceramic carrier in the ligand solution for 5h;

[0067] Weigh 1.90g copper nitrate trihydrate and dissolve in 50mL ethanol solution to obtain copper nitrate solution;

[0068] Filter the soaked alumina ceramic carrier and put it into the copper nitrate solution, react in an oil bath at 80°C under condensing and reflux conditions for 22h, filter, and dry (the drying temperature is 100°C, and the drying time is 2-12h) After obtaining Cu-MOF-Al 2 o 3 Adsorbent.

[0069] The loading of Cu-MOF in this adsorbent is 7.2wt%....

Embodiment 3

[0073] This embodiment provides a method for preparing a porous alumina ceramic loaded Cu-MOF adsorbent, which includes the following steps:

[0074] (1) Preparation of porous alumina ceramic carrier

[0075] 10g alumina powder, 0.5g ZrO 2 Sintering aid, 0.3g sodium polyacrylate, 34.6mL camphene, 5.19mL tert-butanol were mixed and put into a flask, mixed and stirred in an oil bath at 70°C for 12 hours to obtain a uniformly mixed ceramic slurry;

[0076] Inject the ceramic slurry into the forming mold and let it stand for 1 hour, take it out from the mold after solidification, and obtain the ceramic green body;

[0077] Place the demolded alumina ceramic green body at -16°C (freeze in the refrigerator) for 24h, then put it into a vacuum freeze dryer at -40°C, dry it under reduced pressure at 100μHg for 12h, and then take it out , and finally the temperature was raised at a rate of 4°C / min for high-temperature sintering, the temperature was raised to 1500°C, kept for 3 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com