A kind of preparation method of normal temperature oil product desulfurizer

A technology of desulfurizer and oil products, applied in chemical instruments and methods, refining hydrocarbon oil, treating hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

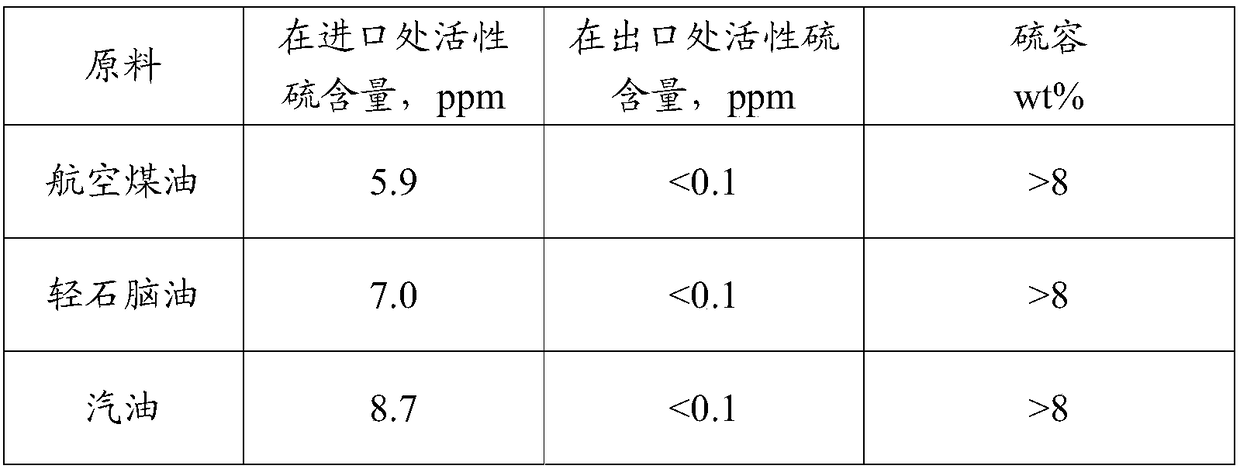

Examples

Embodiment 1

[0090] Embodiment 1: Preparation of normal temperature oil product desulfurizer of the present invention

[0091] The implementation steps of this embodiment are as follows:

[0092] A, preparation of zinc oxide mixture

[0093] Stir and mix 60 parts by weight of zinc oxide, 12 parts by weight of pseudo-boehmite additive and 3 parts by weight of starch binder to obtain the zinc oxide mixture;

[0094] B. Preparation of ferric nitrate solution

[0095] According to the ratio of ferric nitrate in grams to deionized water in milliliters is 15:15, dissolve ferric nitrate in deionized water and continue stirring for 35 minutes to obtain an aqueous solution of ferric nitrate;

[0096] C. Preparation of silver-copper mixture

[0097] According to the ratio of citric acid in grams to deionized water in milliliters as 8:13, dissolve citric acid in deionized water and continue to stir for 8 minutes to obtain an aqueous solution of citric acid; then in grams of citric acid, silver nit...

Embodiment 2

[0102] Embodiment 2: Preparation of normal temperature oil product desulfurizer of the present invention

[0103] The implementation steps of this embodiment are as follows:

[0104] A, preparation of zinc oxide mixture

[0105] 65 parts by weight of zinc oxide, 6 parts by weight of pseudoboehmite and diatomaceous earth mixture (weight ratio 5:1) additives and 4.98 parts by weight of gelatin and carboxymethyl cellulose mixture (weight ratio 3:1.98) are bonded The agent is stirred and mixed uniformly to obtain the zinc oxide mixture;

[0106] B. Preparation of ferric nitrate solution

[0107] According to the ratio of ferric nitrate in grams to deionized water in milliliters as 20:15, dissolve ferric nitrate in deionized water and continue stirring for 28 minutes to obtain an aqueous solution of ferric nitrate;

[0108] C. Preparation of silver-copper mixture

[0109] According to the ratio of citric acid in grams to deionized water in milliliters as 3:12, dissolve citric a...

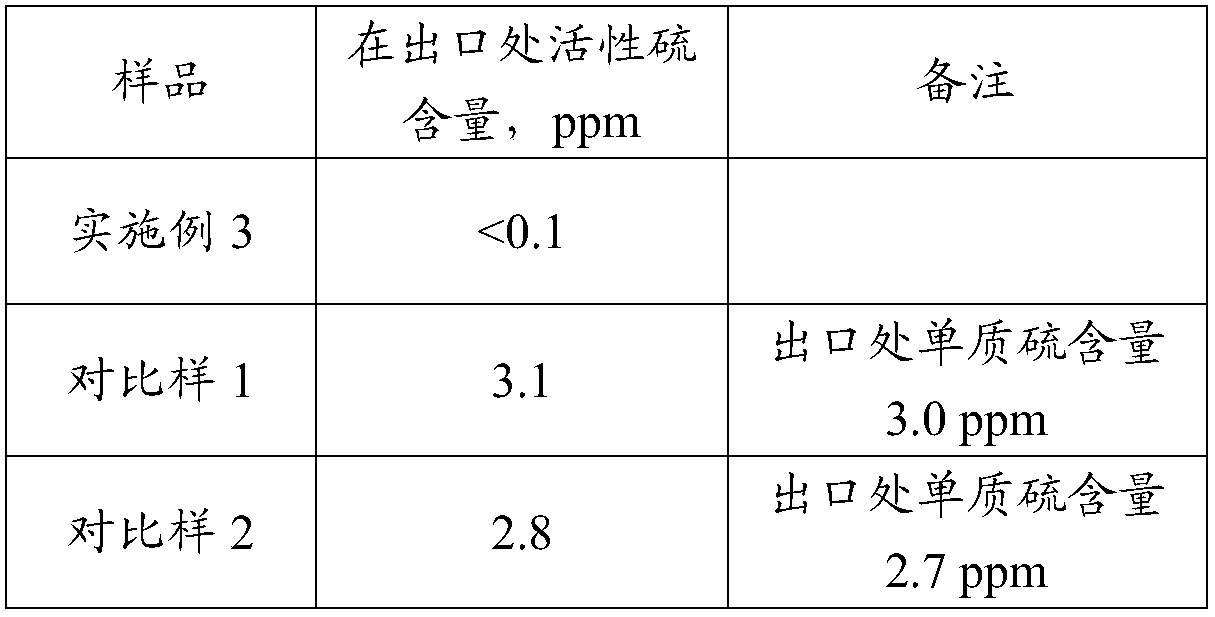

Embodiment 3

[0115] Embodiment 3: Preparation of normal temperature oil product desulfurizer of the present invention

[0116] The implementation steps of this embodiment are as follows:

[0117] A, preparation of zinc oxide mixture

[0118] 68 parts by weight of zinc oxide, 10 parts by weight of pseudo-boehmite and diatomaceous earth mixture (weight ratio 4:1) auxiliary agent and 4 parts by weight of carboxymethyl cellulose, starch and gelatin mixture (weight ratio 2:1: 1) The binder is stirred and mixed uniformly to obtain the zinc oxide mixture;

[0119] B. Preparation of ferric nitrate solution

[0120] According to the ratio of ferric nitrate in grams to deionized water in milliliters as 10:10, dissolve ferric nitrate in deionized water and continue stirring for 30 minutes to obtain an aqueous solution of ferric nitrate;

[0121] C. Preparation of silver-copper mixture

[0122] According to the ratio of citric acid in grams to deionized water in milliliters as 6:19, dissolve citric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com