Production method of Hubei flavored fermented mandarin fish

A production method and technology of mandarin fish, applied in the production field of fermented mandarin fish with Hubei flavor, can solve problems such as different fermentation speeds, poor control of taste and flavor, and influence on product quality uniformity, so as to reduce fishy smell Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

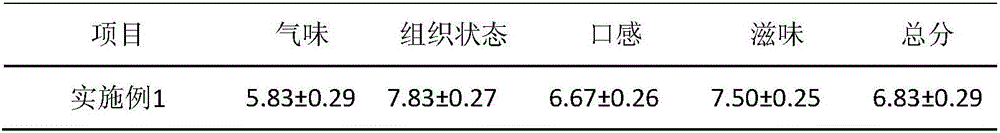

Embodiment 1

[0036] A production method of Hubei flavor fermented mandarin fish, the steps comprising:

[0037] (1) Raw fish: select freshly dead mandarin fish without disease as raw fish, the size is 400-600g / tail.

[0038] (2) Pretreatment: use the dorsal section method to process the raw fish in step (1), and clean the internal organs, fish gills and fish scales, etc., and at the same time, cut diagonally on the back of the fish on both sides, with 3-4 knives on each side , the length of each flower knife is 3-5cm, and the depth is 1-2cm.

[0039] (3) Cleaning: soak the fish body in step (2) in running water at 10°C to remove blood and water for 20 minutes, and then drain the water on the surface.

[0040] (4) Bacteria reduction: immerse the fish body in step (3) in food-grade chlorine dioxide 200 mg / L to remove bacteria on the surface of the fish body, soak for 20 minutes, then rinse with sterile water and drain the surface water.

[0041] (5) Composite deodorization: immerse the fis...

Embodiment 2

[0059] Effects of different bacteria-reducing agents on the total number of colonies in mandarin fish meat:

[0060] Mandarin fish is processed by (1)~(3) steps of embodiment 1, and the fish after cleaning is immersed in sodium hypochlorite solution (100mg / L), chlorine dioxide solution (200mg / L) and ozone water (6mg / L) respectively. L), the ratio of fish meat to liquid is 1:3 (w:w), and the soaking time is 10min. At the same time, a control group is set, and the surface of the fish body is rinsed with sterile water (distilled water boiled and cooled), and then the liquid on the surface is drained. Put it into a ziplock bag (the ziplock bag is sterilized with ultraviolet rays in advance) for later use, and then measure the total number of colonies after the bacteria reduction treatment. The determination of the total number of colonies refers to GB4789.2-2010.

[0061] Table 4 The effect of bacteria reduction on the total number of colonies in mandarin fish meat (mean ± standa...

Embodiment 3

[0065] The effect of deodorization agent on the fishy degree of mandarin fish:

[0066] Mandarin fish is processed by (1)~(4) of embodiment 1, after reducing bacteria, then soak in 6 kinds of deodorizing agents (see table 6) respectively, the deodorizing agent temperature is 25 ℃, time 20min, The ratio of fish meat to deodorizer is 1:3 (w:w). Then measure the fishy degree of the fish meat after the fishy smell removal treatment.

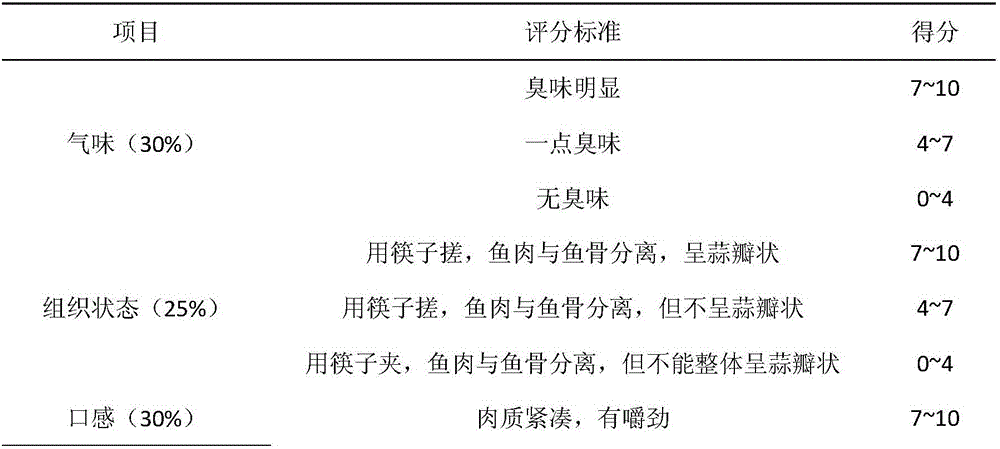

[0067] The degree of fishy smell is obtained by weighted summation of fishy smell and fishy smell, and the evaluation method refers to literature (Lei Yuelei, Zheng Xiaoning, Lu Sufang, Qiu Chaokun, Han Tao. Optimization research on deodorization process of cultured mandarin fish meat perilla juice[J]. Food Industry Science and Technology , 2015,36(327):228-231.) method. The deodorized fish was steamed for 5 minutes at 100°C, and the fishy smell and fishy smell were used as evaluation indicators, and the fishy smell score was obtained by smelling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com