Glove box and atomic layer deposition combination coating equipment

A technology of atomic layer deposition and coating equipment, applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve problems such as material corrosion, and achieve the effect of avoiding side reactions, high efficiency and good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

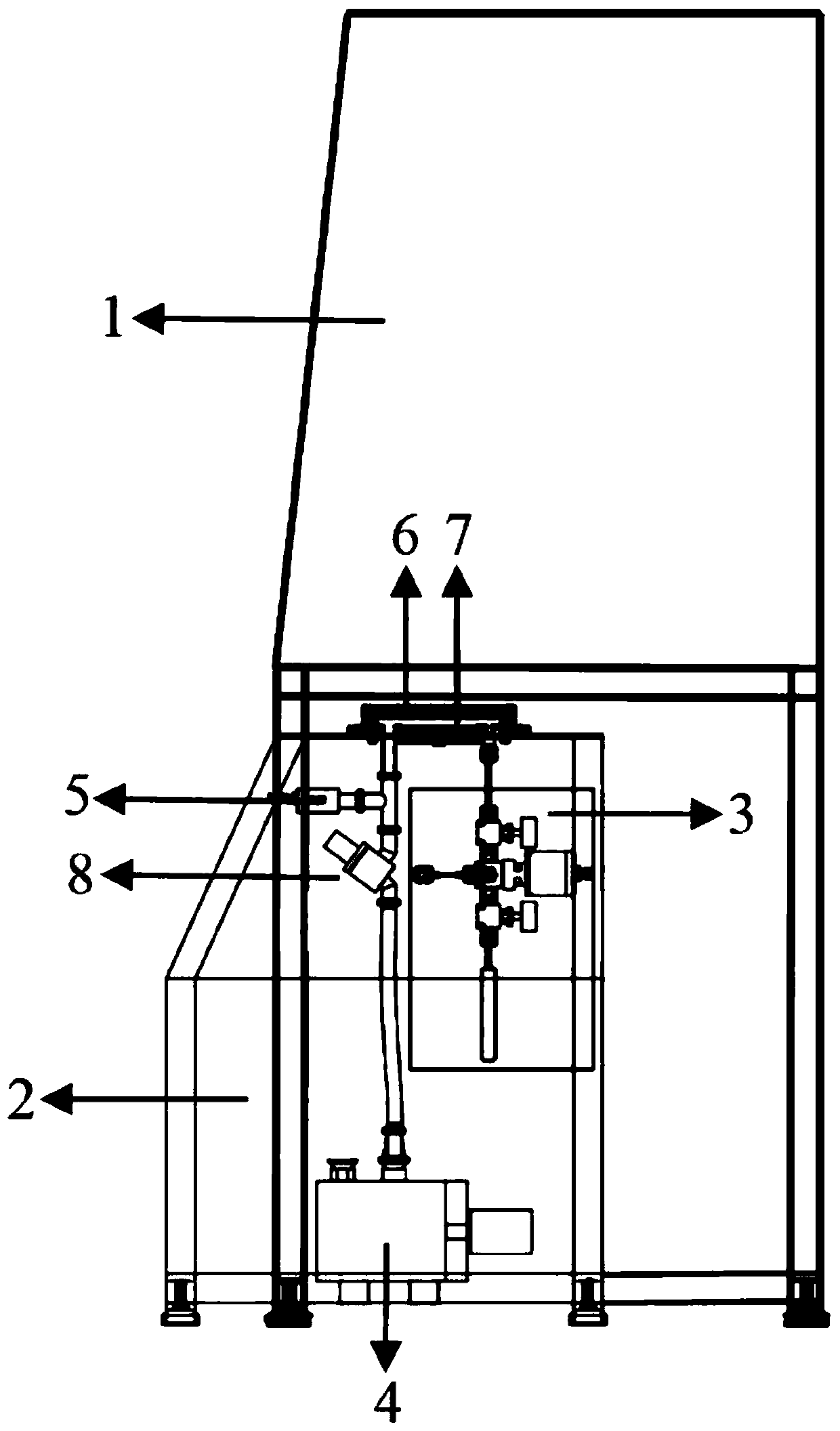

Embodiment 1

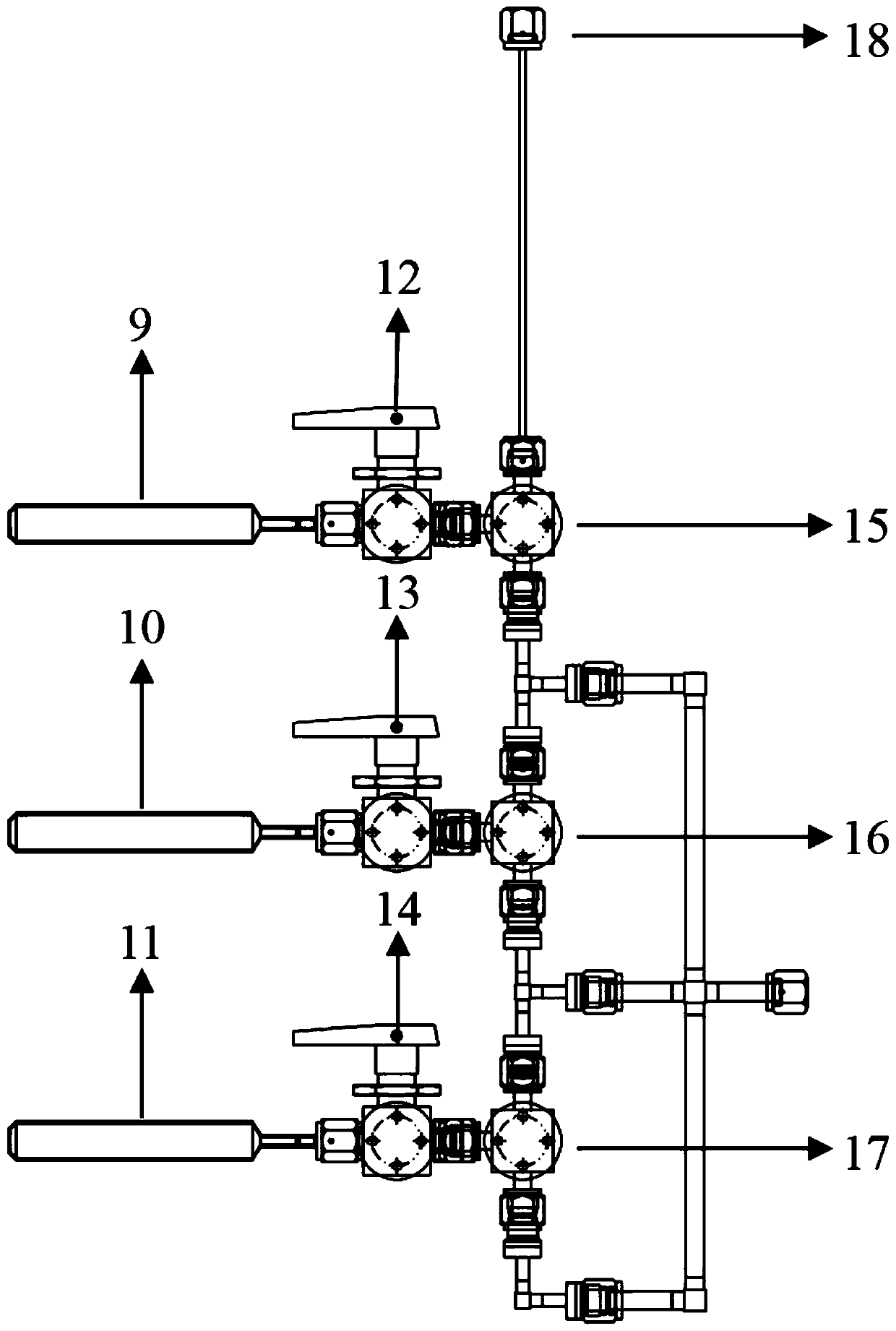

[0034] In the present invention, two paths of precursors TTIP and H 2 O, deposited TiO 2 As an example to elaborate:

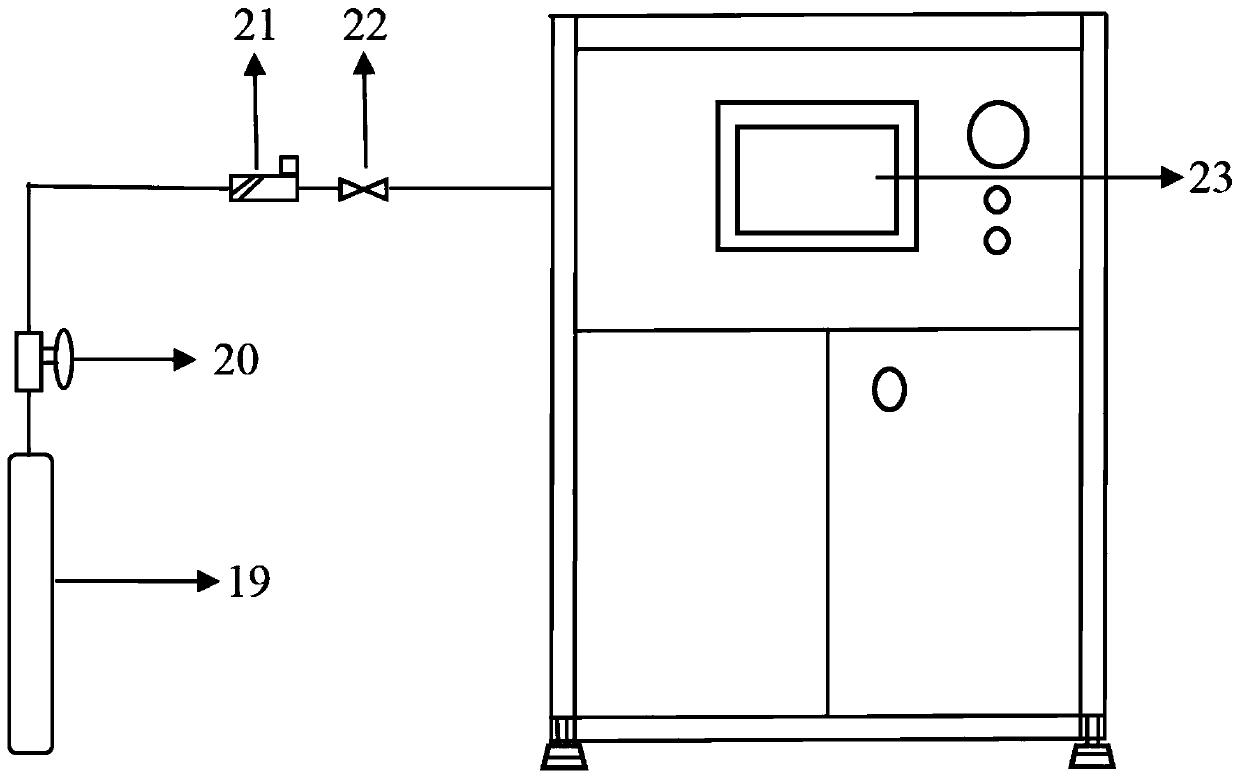

[0035] The first precursor source bottle 9 is filled with H 2 O precursor, the third precursor source bottle 11 is equipped with TTIP precursor. First prepare the sample to be deposited inside the glove box, open the metal cover above the vacuum reaction chamber 6, place the sample on the heating substrate 7, cover the metal cover, close the vacuum reaction chamber 6, and then open the PLC program control system, Control and start the vacuum mechanical pump 4, open the two ventilation valves 8 to pump the vacuum reaction chamber 6 and the system pipeline air pressure to less than 0.1Pa; set the third precursor source bottle 11 equipped with TTIP, so that the temperature reaches 85 degrees Celsius, and set the TTIP The temperature of the inlet pipeline of the precursor reaches 95 degrees Celsius, and the vacuum reaction chamber 6 and the heating substrate st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com