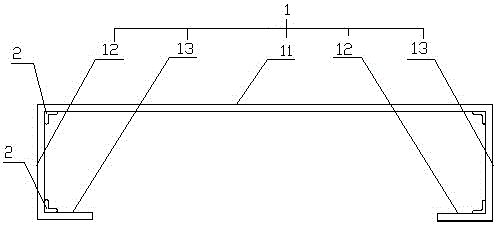

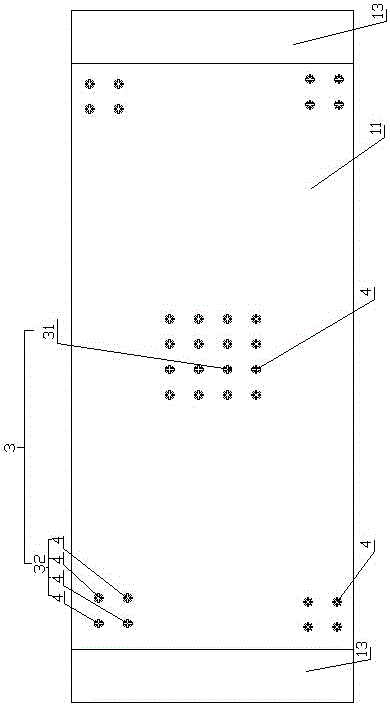

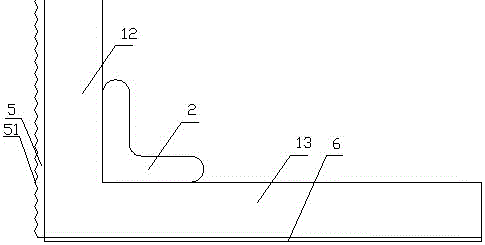

Protection side connection cover plate specially for bus connector

A busbar connector and side connection technology, which is applied to cooling busbar devices, fully enclosed busbar devices, coatings, etc. Improve the anti-electric performance, facilitate heat dissipation, and have the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The special protective side connection cover plate for the busbar connector, wherein the preparation method of the antistatic layer is as follows:

[0039] (1) Add 45 parts of phenolic resin and 18 parts of modified epoxy resin into a mixer and stir for 2 hours to obtain mixture A, calculated in parts by weight;

[0040] (2) Add 12 parts of microsilica powder, 15 parts of cyclomethicone, 11 parts of polyethylene glycol, and 22 parts of distilled water into a mixer and stir for 1 hour to obtain mixture B, calculated in parts by weight;

[0041] (3) Heat the mixture A, stir during the heating process, the stirring rate is 55r / min, add and stir with the mixture B after heating to 150 degrees Celsius, the mixture A and the mixture B are mixed in a weight ratio of 3:4; the stirring rate is the same as Keep the temperature constant. After stirring for 10 minutes, lower the temperature to 90 degrees Celsius. After continuing to mix and stir for 1.5 hours, cool naturally to roo...

Embodiment 2

[0043] The special protective side connection cover plate for the busbar connector, wherein the preparation method of the antistatic layer is as follows:

[0044] (1) Add 65 parts of phenolic resin and 28 parts of modified epoxy resin into a mixer and stir for 3 hours to obtain mixture A, calculated in parts by weight;

[0045] (2) Add 22 parts of silicon micropowder, 22 parts of cyclomethicone, 25 parts of polyethylene glycol, and 28 parts of distilled water into a mixer and stir for 3 hours to obtain mixture B, calculated in parts by weight;

[0046] (3) Heat the mixture A, stir during the heating process, the stirring rate is 55r / min, add and stir with the mixture B after heating to 150 degrees Celsius, the mixture A and the mixture B are mixed in a weight ratio of 5: 8; the stirring rate is the same as Keep the temperature constant. After stirring for 30 minutes, lower the temperature to 100 degrees Celsius. After continuing to mix and stir for 2 hours, cool naturally to r...

Embodiment 3

[0048] The special protective side connection cover plate for the busbar connector, wherein the preparation method of the antistatic layer is as follows:

[0049] (1) Add 55 parts of phenolic resin and 21 parts of modified epoxy resin into a mixer and stir for 2.5 hours to obtain mixture A, calculated in parts by weight;

[0050](2) Add 17 parts of silicon micropowder, 18 parts of cyclomethicone, 13 parts of polyethylene glycol, and 25 parts of distilled water into a mixer and stir for 1.8 hours to obtain mixture B, calculated in parts by weight;

[0051] (3) Heat the mixture A, stir during the heating process, the stirring rate is 55r / min, add and stir with the mixture B after heating to 150 degrees Celsius, the mixture A and the mixture B are mixed in a weight ratio of 4:7; the stirring rate is the same as Keep the temperature constant. After stirring for 25 minutes, lower the temperature to 95 degrees Celsius. After continuing to mix and stir for 2 hours, cool naturally to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com