Heating apparatus for x-ray inspection

a technology of x-ray inspection and heating apparatus, which is applied in the direction of ohmic-resistance heating, material analysis using wave/particle radiation, instruments, etc., can solve the problems of sample temperature drop, insufficient control of temperature, and inability to conduct accurate inspection, etc., to achieve high maintenance properties, high durability, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

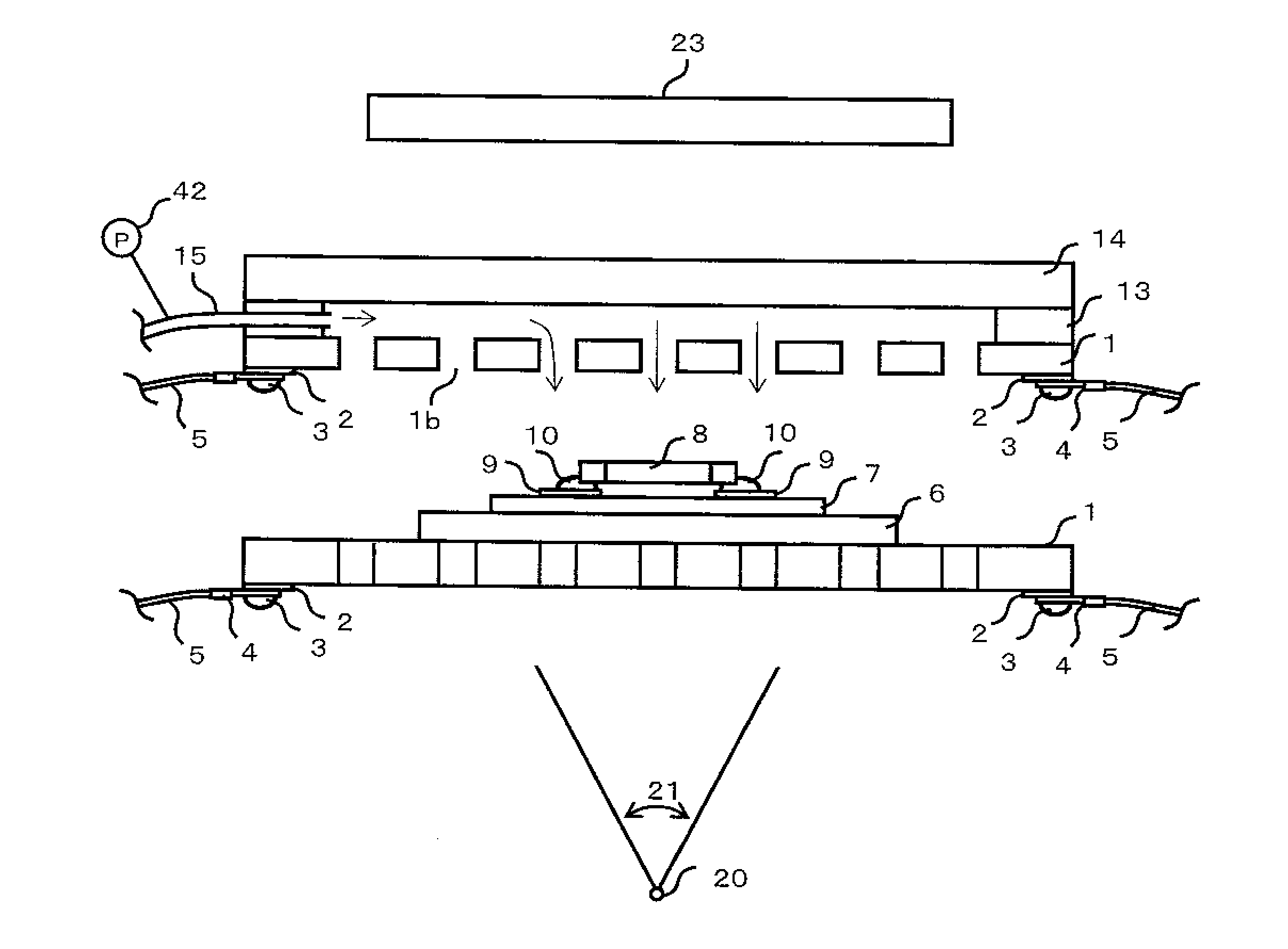

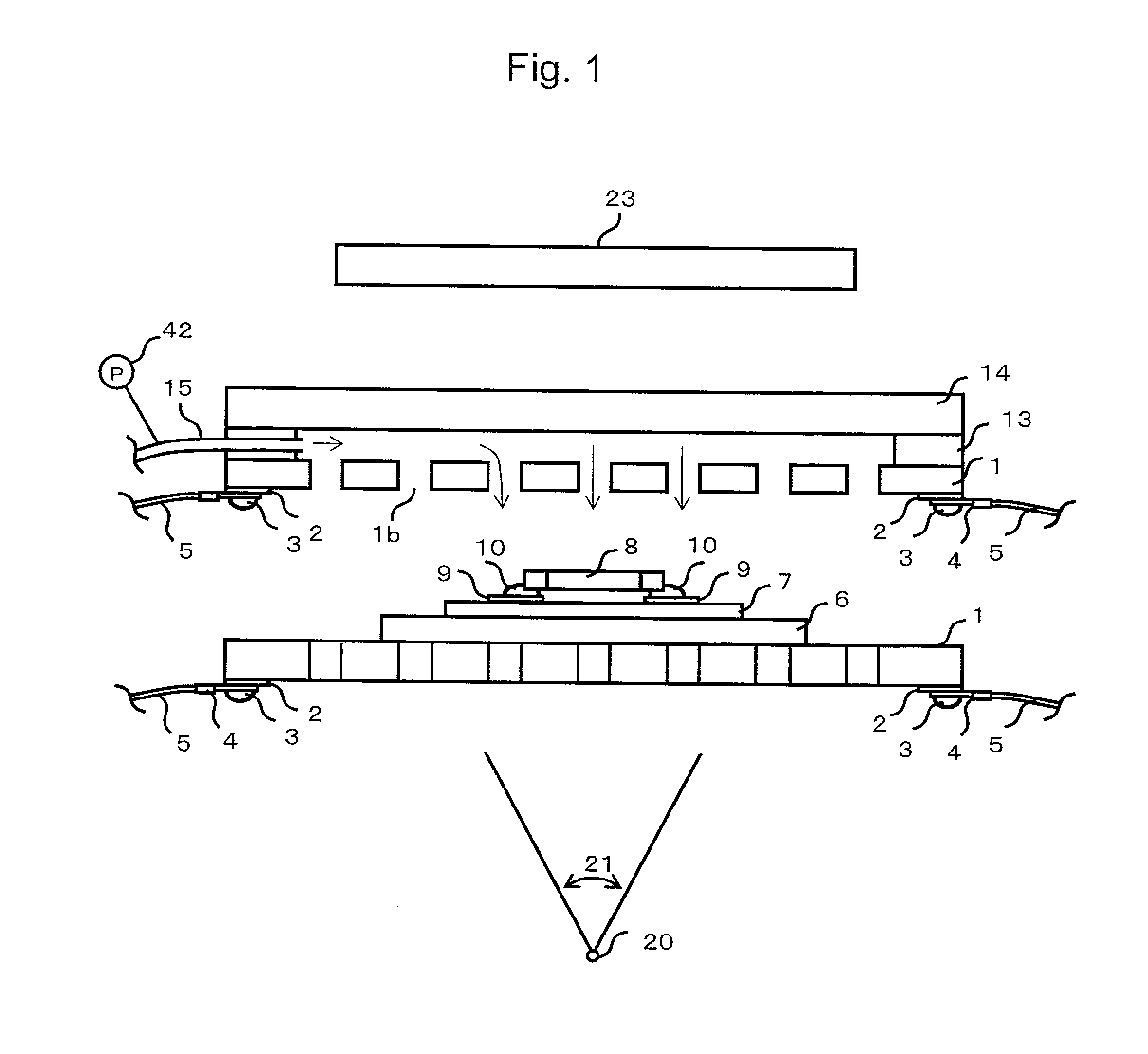

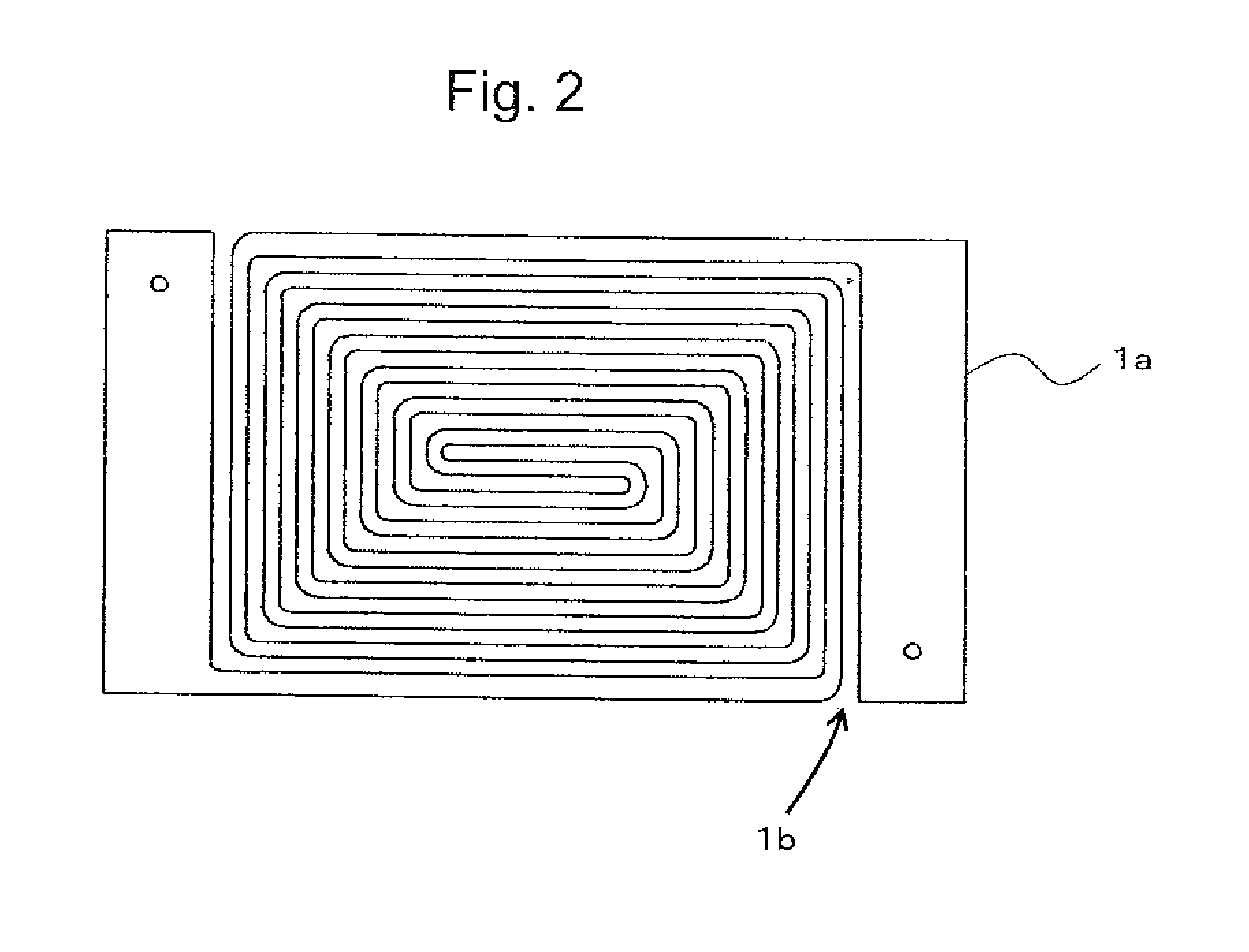

[0140]Planar heaters made of a carbon-fiber reinforced carbon composite material plate were disposed above and below and formed into the shape shown in FIG. 1. Then, they were used to fabricate a heating apparatus.

embodiment 2

[0141]Planar heaters made of a carbon-fiber reinforced carbon composite material plate were disposed above and below and formed into the shape shown in FIG. 9. Then, they were used to fabricate a heating apparatus.

embodiment 3

[0142]Planar heaters made of a carbon-fiber reinforced carbon composite material plate and ceramics plates were used to fabricate the heating apparatus shown in FIG. 10 and FIG. 16.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat resistant temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com