A preparation method of μ=60 iron-nickel soft magnetic powder core

A magnetic powder core, iron-nickel technology, applied in the field of preparation of μ = 60 iron-nickel soft magnetic powder core, can solve the problem of poor DC superposition performance and loss performance of the magnetic powder core, can not eliminate the internal stress of the magnetic core well, and affect the power of the magnetic powder core Loss and other issues, to achieve the effect of high DC superposition performance, simple equipment and process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

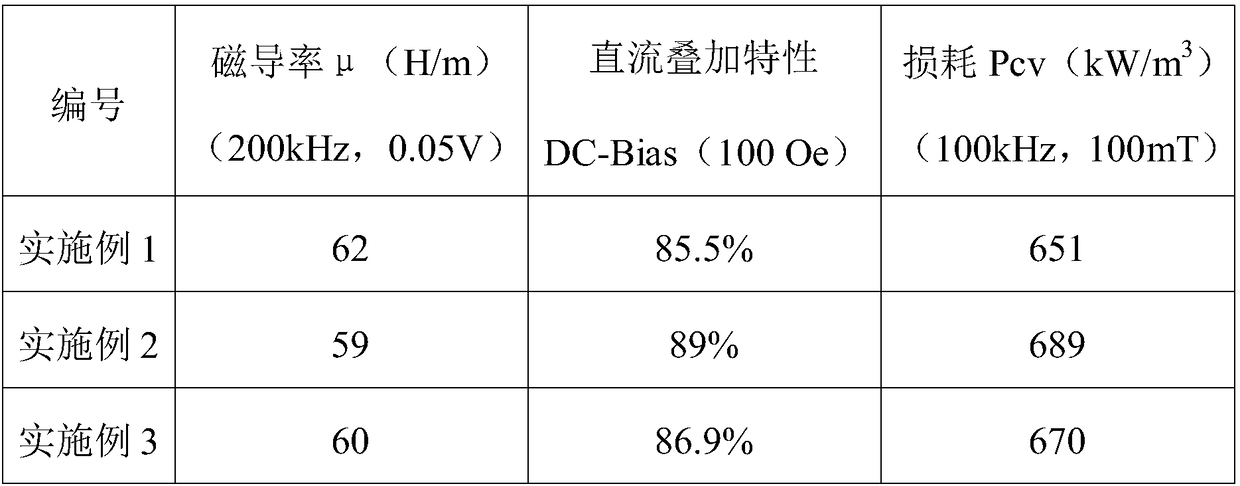

Embodiment 1

[0022] Take the gas-atomized FeNi powder, wherein the content of nickel is 50%, and the balance is iron, and use an ultrasonic vibrating sieve to classify it according to two particle sizes of +45 μm and -45 μm, and then press +45 μm:-45 μm=2:3 Mix the ratio evenly; put it in the annealing furnace, blow nitrogen, and keep it warm at 800°C for 6 hours; add the magnetic powder into the aluminum dihydrogen phosphate solution and heat it to 150°C and roast until dry. After cooling, add the magnetic powder into the water glass and kaolin to mix The solution is heated to 150°C and roasted until dry, wherein the amount of aluminum dihydrogen phosphate is 1% of the weight of the iron-nickel magnetic powder, the amount of water glass is 1.2% of the weight of the iron-nickel magnetic powder, and the amount of kaolin is 0.8% of the weight of the iron-nickel magnetic powder. %; add molybdenum disulfide 1% of the weight of iron-nickel magnetic powder as a release agent before pressing and f...

Embodiment 2

[0024] Take the gas-atomized FeNi powder, wherein the content of nickel is 45%, and the balance is iron, and use an ultrasonic vibrating sieve to classify it according to two particle sizes of +45 μm and -45 μm, and then press +45 μm:-45 μm=2:3 Mix the ratio evenly; put it into an annealing furnace, pass hydrogen, and keep it warm at 900°C for 1 hour; add the magnetic powder into the aluminum dihydrogen phosphate solution and heat it to 180°C and roast until dry. After cooling, add the magnetic powder into the water glass and kaolin to mix The solution is heated to 180°C and roasted until dry, wherein the amount of aluminum dihydrogen phosphate is 2% of the weight of the iron-nickel magnetic powder, the amount of water glass is 0.5% of the weight of the iron-nickel magnetic powder, and the amount of kaolin is 0.5% of the weight of the iron-nickel magnetic powder. %; Add 0.8% of iron-nickel magnetic powder weight stearate as a release agent before pressing and forming. After mix...

Embodiment 3

[0026] Take the gas-atomized FeNi powder, wherein the content of nickel is 42%, and the balance is iron, and use an ultrasonic vibrating sieve to classify it according to two particle sizes of +45 μm and -45 μm, and then press +45 μm:-45 μm=2:3 Mix the ratio evenly; put it into the annealing furnace, pass the mixed gas of nitrogen and hydrogen, and keep it warm at 850°C for 3h; add the magnetic powder into the aluminum dihydrogen phosphate solution and heat it to 120°C and roast until dry, after cooling, add the magnetic powder into the Heating to 120°C in a mixed solution of water glass and kaolin and roasting until dry, wherein the amount of aluminum dihydrogen phosphate is 0.5% of the weight of the iron-nickel magnetic powder, the amount of water glass is 2% of the weight of the iron-nickel magnetic powder, and the amount of kaolin is 0.5% of the weight of the iron-nickel magnetic powder. 1% of the weight of nickel magnetic powder; before pressing and forming, add a mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| core loss | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com