A kind of 2-h benzopyran derivative and its synthetic method

A technology of benzopyran derivatives and synthesis methods, applied in directions such as organic chemistry, to achieve the effects of low toxicity of raw materials, good adaptability and easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

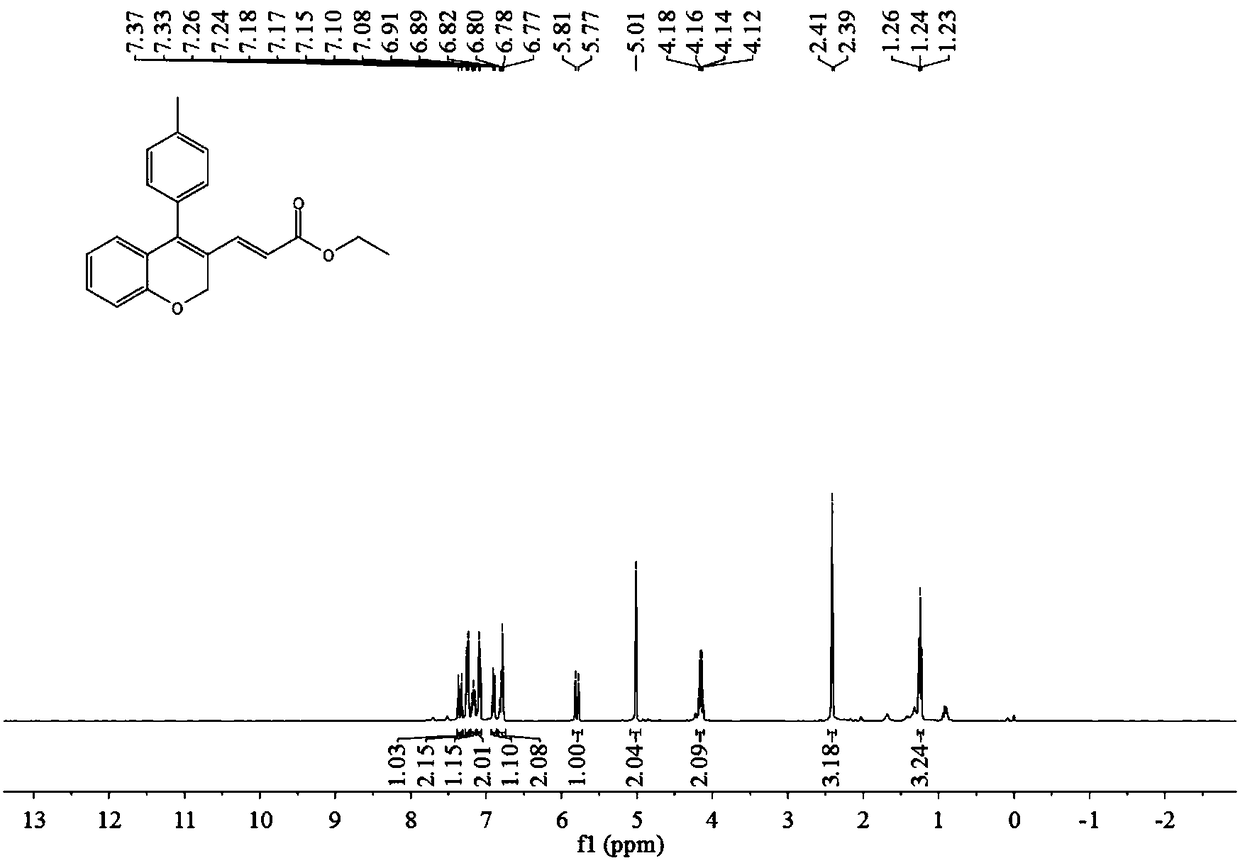

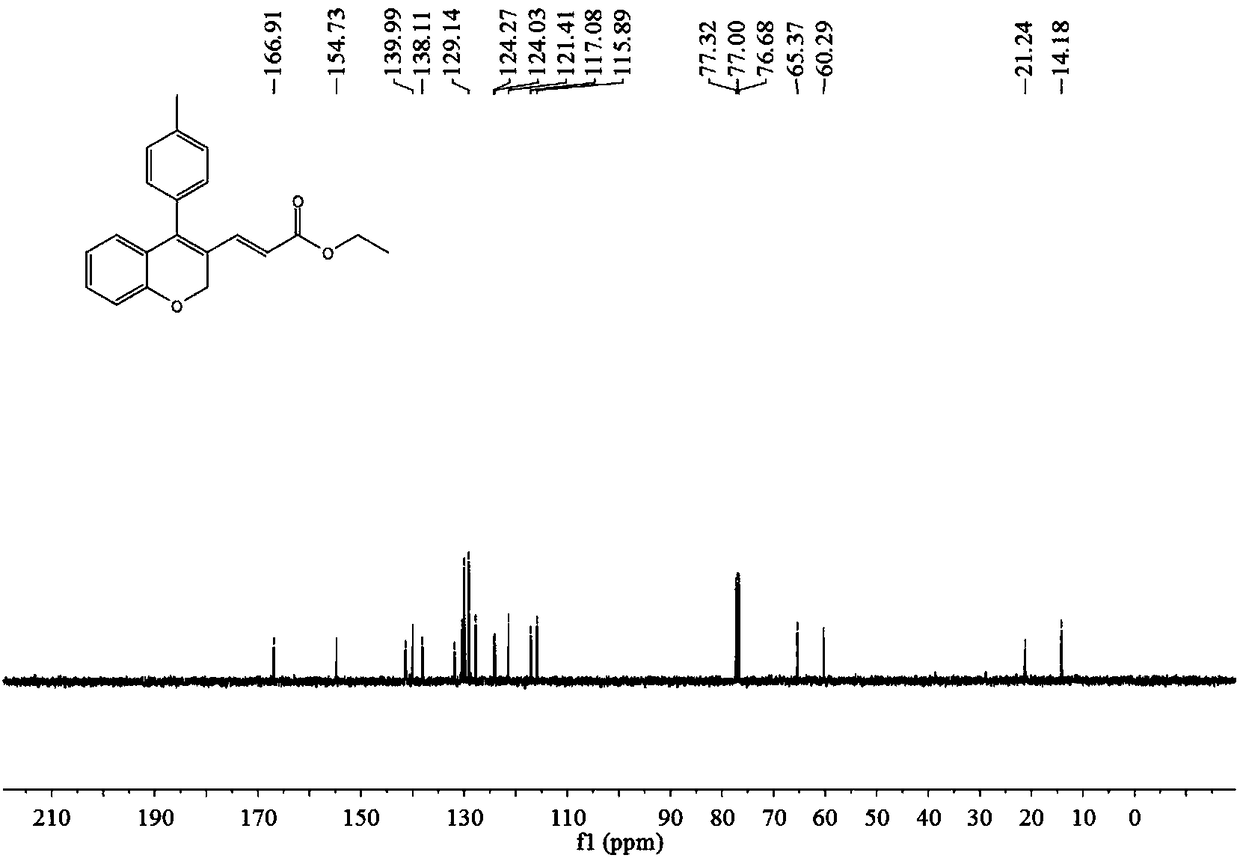

[0040] Add 0.25 mmoles of phenyl-p-tolyl propargyl ether to a screw-top test tube (preparation method: add 5 mmoles of phenyl propargyl ether, 5 mmoles of p-methyliodobenzene, 0.25 mmoles of Phenylphosphine palladium, 0.5 millimoles of cuprous iodide, 3 milliliters of triethylamine, stirred and reacted at room temperature for 3 hours, then stopped stirring. The reaction mass was decompressed and rotary evaporated to remove the solvent, and then separated and purified by column chromatography to obtain the Raw materials, the column chromatography eluent used is petroleum ether) (reference: V.S.Prasada RaoLingam.Tetrahedron Letters, 2008,49(27), 4260), 0.25 mmol ethyl acrylate, 0.025 mmol palladium chloride, 0.25 mmol Mole of silver oxide and 2 ml of acetonitrile were stirred and reacted at 80°C for 5 hours, then heating and stirring were stopped, and cooled to room temperature. The reaction material was decompressed and rotary evaporated to remove the solvent, and then separate...

Embodiment 2

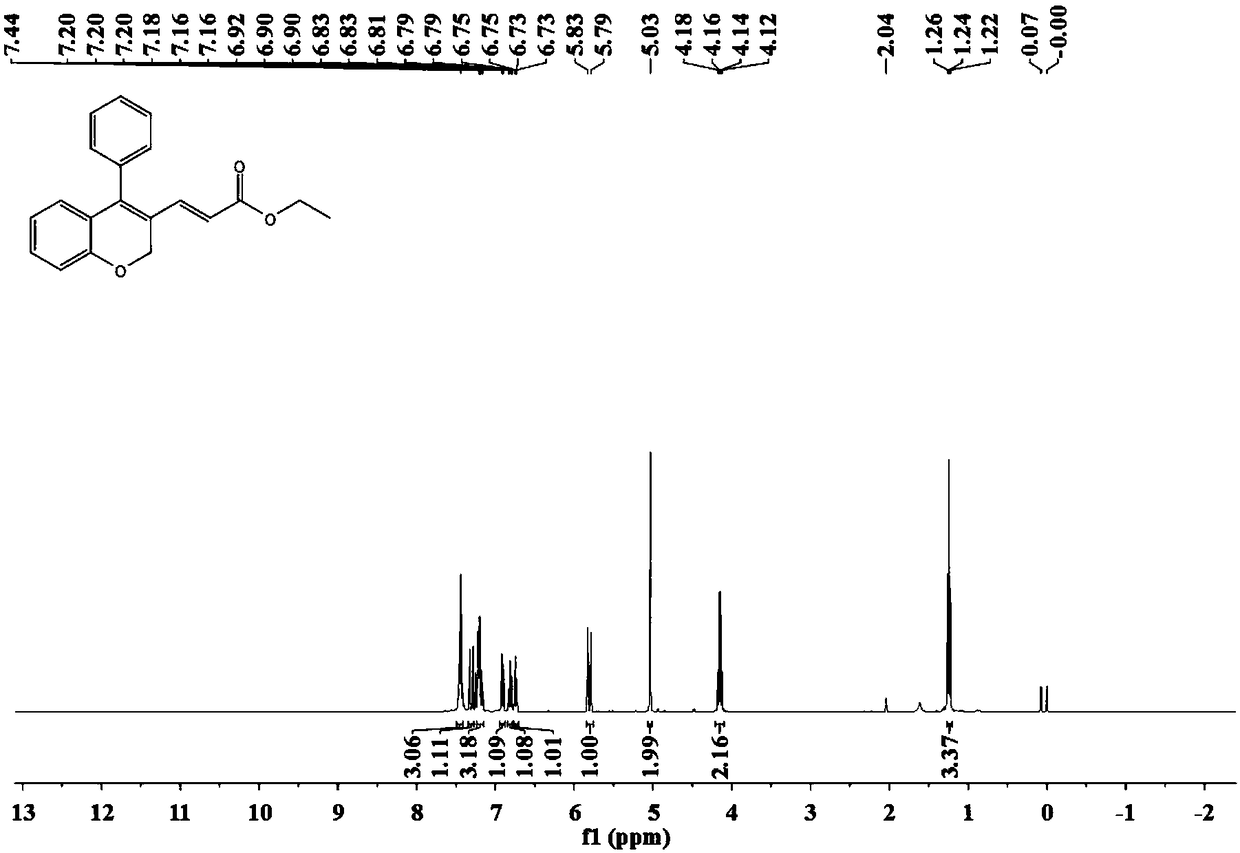

[0042] Add 0.25 mmol phenyl-p-tolyl propargyl ether, 0.40 mmol ethyl acrylate, 0.020 mmol palladium acetate, 0.50 mmol silver acetate, 3 ml toluene to a screw-top test tube, stir and react at 70°C for 6 hours, stop Heat and stir, and cool to room temperature. The reaction material was decompressed and rotary evaporated to remove the solvent, and then separated and purified by column chromatography to obtain 2-H benzopyran derivatives. The column chromatography eluent used was petroleum ether:ethyl acetate with a volume ratio of 5:1 Mixed solvents, yield 80%.

Embodiment 3

[0044] Add 0.25 mmoles of phenyl-p-tolyl propargyl ether, 0.30 mmoles of ethyl acrylate, 0.025 mmoles of palladium carbon, and 2 ml of acetonitrile into a screw-top test tube, cover with an oxygen bulb, stir and react at 90°C for 30 hours, then stop heating And stir, cool to room temperature. The reaction material was decompressed and rotary evaporated to remove the solvent, and then separated and purified by column chromatography to obtain 2-H benzopyran derivatives. The column chromatography eluent used was petroleum ether:ethyl acetate with a volume ratio of 1:1 Mixed solvents, yield 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com