Vehicle-mounted large-capacity water tank

A large-capacity, water tank technology, applied in large containers, containers, underwater structures, etc., can solve the problems of fixed seat impact, the water tank cannot effectively prevent cold, and the water tank cannot continue to supply water, etc., and achieves the effect of convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings.

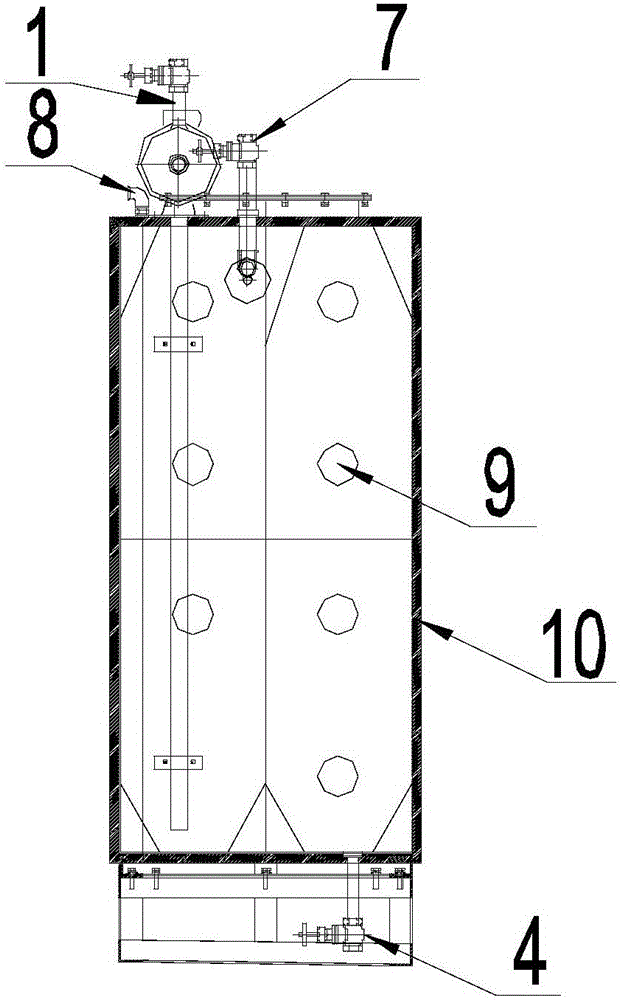

[0035] like Figure 1-3 As shown, a vehicle-mounted large-capacity water tank includes a water tank body 12, a water inlet 7, a water outlet 11, an overflow port 8, a sewage outlet 4, a floating ball liquid level valve 2, a self-priming centrifugal pump 1, and a visible liquid level. Mirror 3 , fixed seat 5 , inspection hole 61 , anti-wave board 9 , thermal insulation cotton 10 . The water tank body 12 is fixed on the fixing base 5 . The water tank body 12 is a double-layer stainless steel structure, which can withstand high corrosion and high humidity environments. The double-layer structure designed interlayer is filled with thermal insulation cotton 10, which can effectively prevent the freezing and expansion of the water tank caused by the low temperature environment. s damage.

[0036] The water inlet 7 and the overflow port 8 are arranged on the top surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com