Energy-saving heat preservation box

A heat preservation box and box body technology, applied in the field of heat preservation, can solve the problems of complex structure of energy-saving heat preservation box, unsuitable for daily use, inconvenient use, etc., and achieve the effect of improving heat preservation performance, improving heat preservation performance, and good particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

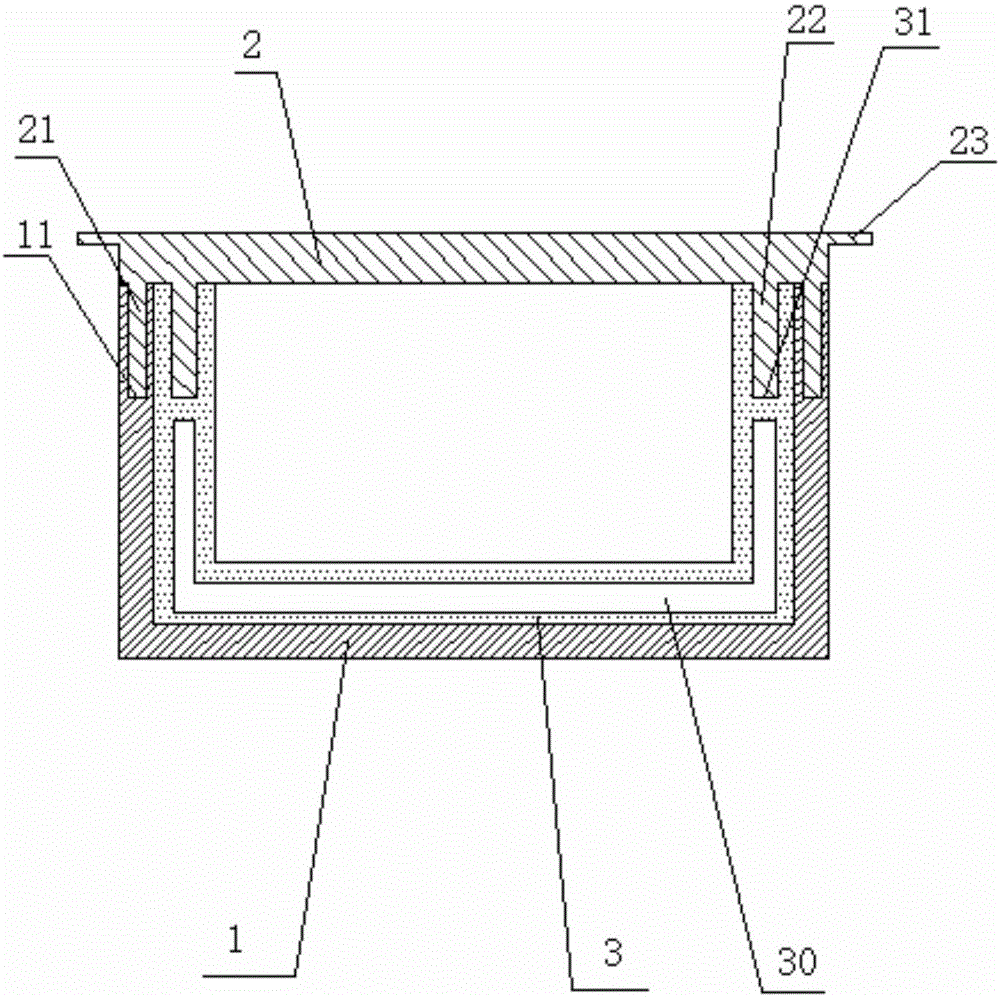

[0032] like Figure 1 to Figure 2 As shown, the present invention provides an energy-saving heat preservation box, comprising: a box body 1 , an insulation lining 3 arranged inside the box body 1 , and a box cover 2 arranged on the top of the box body 1 . Wherein, the material of the box body 1 and the box cover 2 can be polyurethane foam plastics. The material of the thermal insulation lining 3 can be food-grade plastics.

[0033] Specifically, the end surface of the top of the box body 1 is provided with a first sealing groove 11; the end surface of the top of the thermal insulation liner 3 is provided with a second sealing groove 31; the lower surface of the box cover 2 is provided with a first sealing strip 21 corresponding to the first sealing groove 11 ; The lower surface of the box cover 2 is provided with a second sealing strip 22 corresponding to the second sealing groove 31 ; When in use, the first sealing strip 21 and the second sealing strip 22 of the box cover 2...

Embodiment 2

[0035] The thermal insulation lining material is made of the following components in parts by mass:

[0036] 30 parts silicate, 35 parts closed cell perlite, 20 parts magnesite, 5 parts limestone, 5 parts high territory, 3 parts hydroxypropyl methylcellulose, 2 parts polydatin.

[0037] The preparation method of the thermal insulation lining material, the steps are as follows:

[0038] ①. Add 30 parts of silicate and 35 parts of closed-cell perlite into the mixer, and stir and mix for 30 minutes;

[0039] ②. Add 20 parts of magnesite and 5 parts of limestone into the mixer, and stir and mix for 60 minutes;

[0040] ③. Add 5 parts of high territory and 3 parts of hydroxypropyl methylcellulose into the mixer, and stir and mix for 20 minutes;

[0041] ④. Add 2 parts polydatin into the mixer, stir and mix for 5 minutes;

[0042] ⑤. The mixed material is transferred to a ball mill and pulverized to obtain a thermal insulation lining material.

Embodiment 3

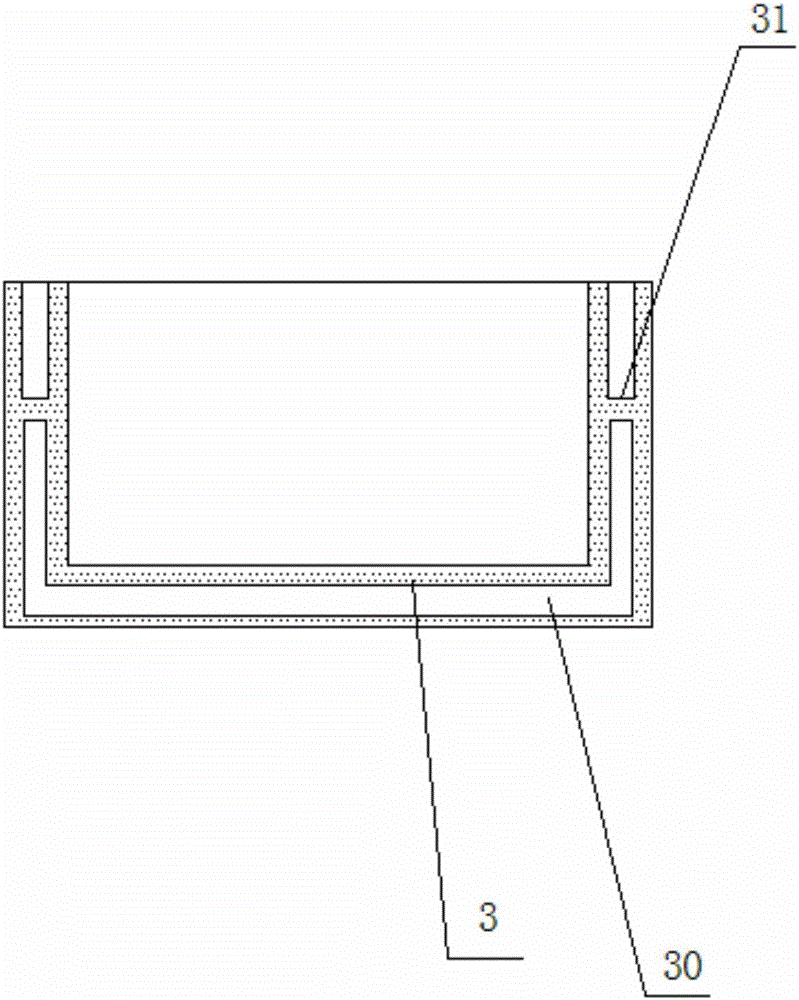

[0044] The thermal insulation lining of the energy-saving thermal insulation box has a double-layer structure, and a vacuum insulation cavity is arranged inside; the thermal insulation lining is made of thermal insulation lining material.

[0045] The manufacturing method of the thermal insulation inner lining of the energy-saving thermal insulation box, the steps are as follows:

[0046] ①. Design the sand casting mold according to the structural shape of the thermal insulation lining;

[0047] 2. Heat the thermal insulation lining material (prepared in Example 2) to melt, and cast it into the mould;

[0048] ③, cooling down, demoulding, and polishing the surface;

[0049] ④. Put it into a constant temperature furnace for constant temperature heat treatment for 1 hour, and the temperature in the constant temperature furnace is 300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com