Method for synthesizing Cu-SSZ-13 molecular sieve catalyst by one step

A technology of molecular sieves and catalysts, which is applied in the field of one-step synthesis of Cu-SSZ-13 molecular sieve catalysts, can solve the problems of reducing the hydrothermal stability of catalysts, high cost of template agents, and high dosage of template agents, so as to achieve optimal hydrothermal aging performance, solid The effect of high phase yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

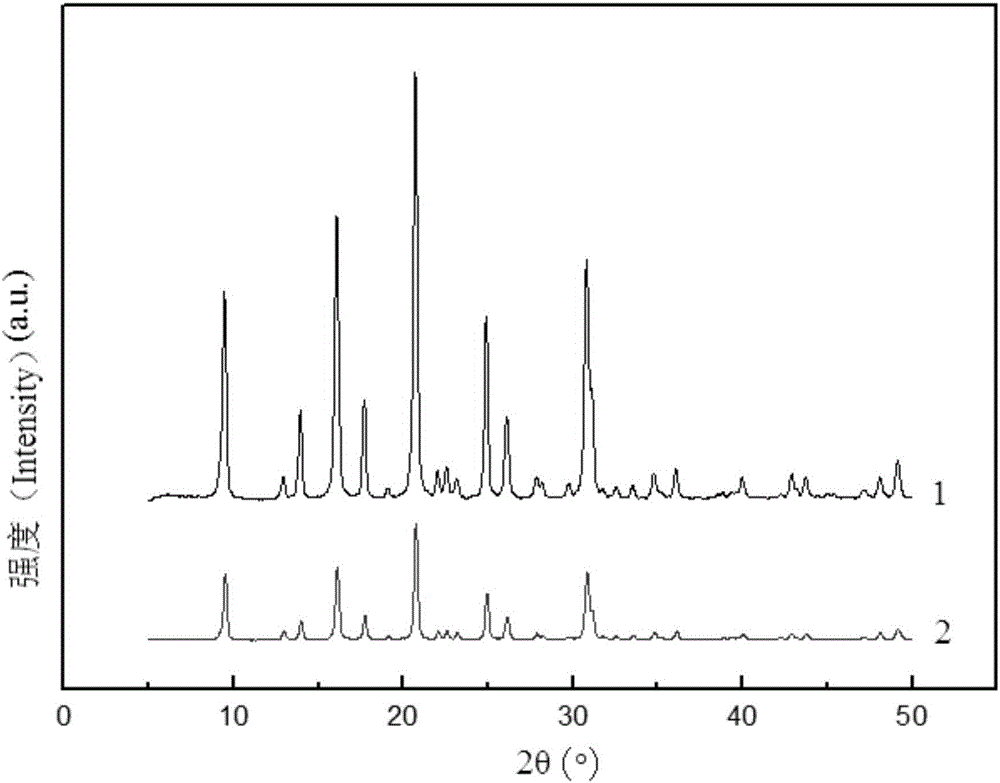

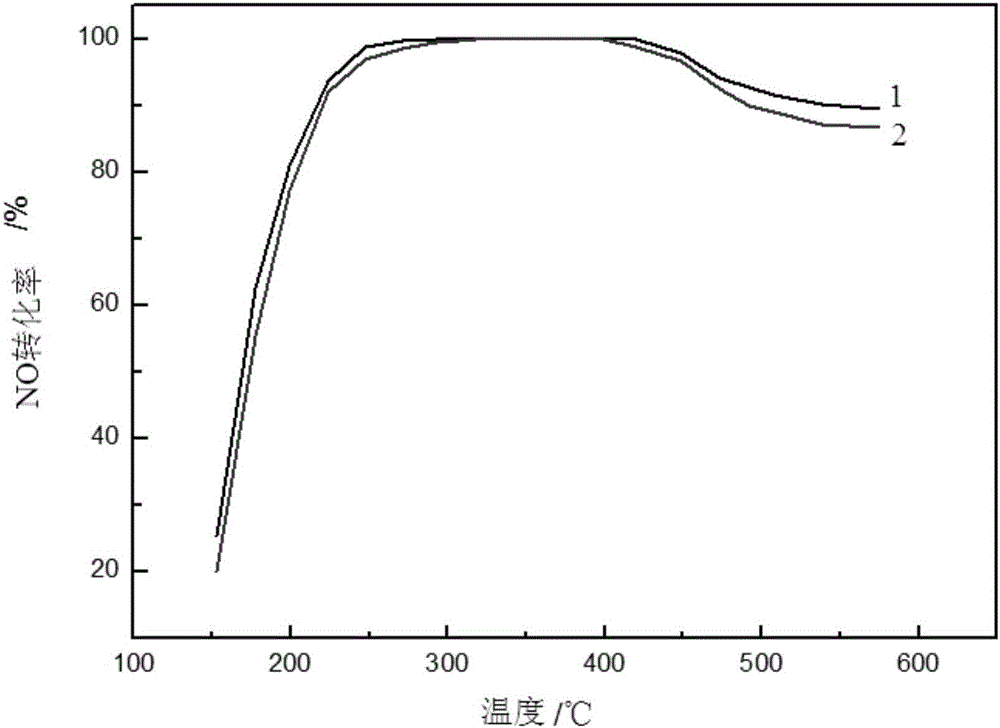

Embodiment 1

[0022] (1) First, N,N,N-trimethyl-1-adamantane ammonium hydroxide, diethylamine and NaOH aqueous solution are mixed, and the complex of copper acetate and TEPA is added, and after thorough stirring, pseudoboehmite and Silica sol with a solid content of 20% and stir until the mixture is uniform; the molar ratio of each component in the mixed solution to SiO 2 :Al 2 O 3 :Na 2 O:R:T:Cu-TEPA:H 2 O is 1:0.05:0.01:0.05:0.2:0.03:25, wherein R is N,N,N-trimethyl-1-adamantane ammonium hydroxide, and T is diethylamine; after stirring for 3 hours, the mixed solution Loaded into a stainless steel reactor lined with tetrafluoroethylene or para-polyphenylene, and crystallized at 160°C for 4 days;

[0023] (2) Wash the obtained product by suction filtration for several times until the solution is neutral, and dry the obtained solid product in a 100 °C oven for 10 hours; dry the dried solid in a muffle furnace at 5 °C / min The temperature was raised to 600° C. and calcined for 2 hours to ...

Embodiment 2

[0027] (1) First, N,N,N-trimethyl-1-adamantane ammonium hydroxide, tetramethylammonium hydroxide and NaOH aqueous solution were mixed, and the complex of copper acetate and TEPA was added, and the pseudo-thin was added after thorough stirring. The diaspore and the silica sol with a solid content of 30% are stirred until they are evenly mixed; the molar ratio of each component in the mixed solution to SiO 2 :Al 2 O 3 :Na 2 O:R:T:Cu-TEPA:H 2 O is 1:0.025:0.05:0.15:0.1:0.03:30, wherein R is N,N,N-trimethyl-1-adamantane ammonium hydroxide, and T is tetramethylammonium hydroxide; after stirring for 3 hours The mixed solution was put into a stainless steel reactor lined with tetrafluoroethylene or para-polyphenylene, and crystallized at 180°C for 3.5 days;

[0028] (2) The product obtained by crystallization is washed several times by centrifugation until the solution is neutral, and the obtained solid product is dried in a 100°C oven for 10 hours; the dried solid is heated in a...

Embodiment 3

[0030](1) First, N,N,N-trimethyl-1-adamantane ammonium hydroxide, tetraethylammonium hydroxide and NaOH aqueous solution are mixed, and the complex of copper acetate and TEPA is added, and the aluminum sol is added after stirring evenly. and fumed silica and stir until the mixture is uniform; the molar ratio of each reaction raw material in the mixed solution is SiO 2 :Al 2 O 3 :Na 2 O:R:T:Cu-TEPA:H 2 O is 1:0.038:0.025:0.1:0.2:0.03:22, where R is N,N,N-trimethyl-1-adamantane ammonium hydroxide, T is tetraethylammonium hydroxide; stir for 3 hours Then, the mixed solution was loaded into a stainless steel reactor lined with tetrafluoroethylene or para-polyphenylene, and crystallized at 140°C for 6 days;

[0031] (2) The product obtained from crystallization is washed several times by means of plate and frame filtration until the solution is neutral, and the obtained solid product is dried in an oven at 100 °C for 10 hours; the dried solid is dried in a muffle furnace at 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com