Preparation and application method of titanium dioxide loaded highly dispersed platinum composite photocatalytic material

A composite photocatalysis and titanium dioxide technology, which is applied in the field of titanium dioxide nanosheet-loaded noble metal composite materials and titanium dioxide photocatalysis, can solve the problems of cumbersome methods and high reagent consumption, achieve good repeatability, improve separation efficiency, and uniform particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

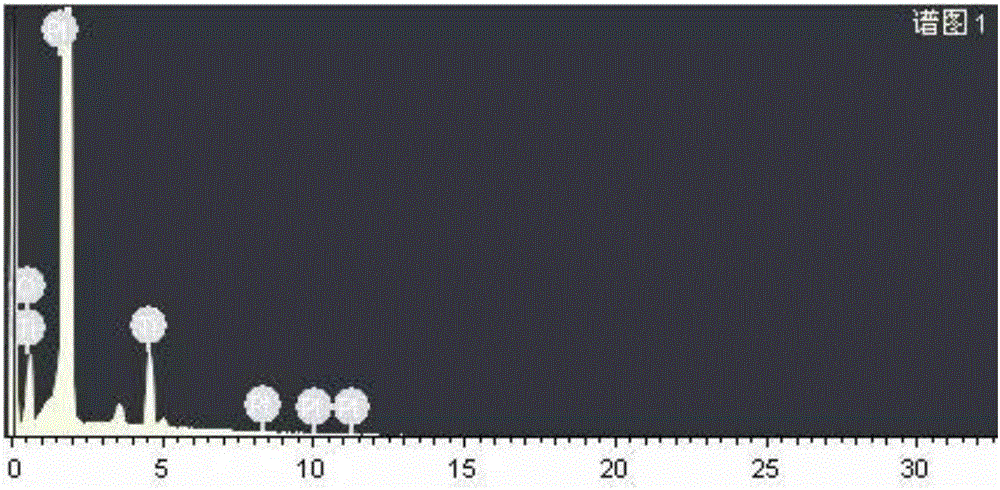

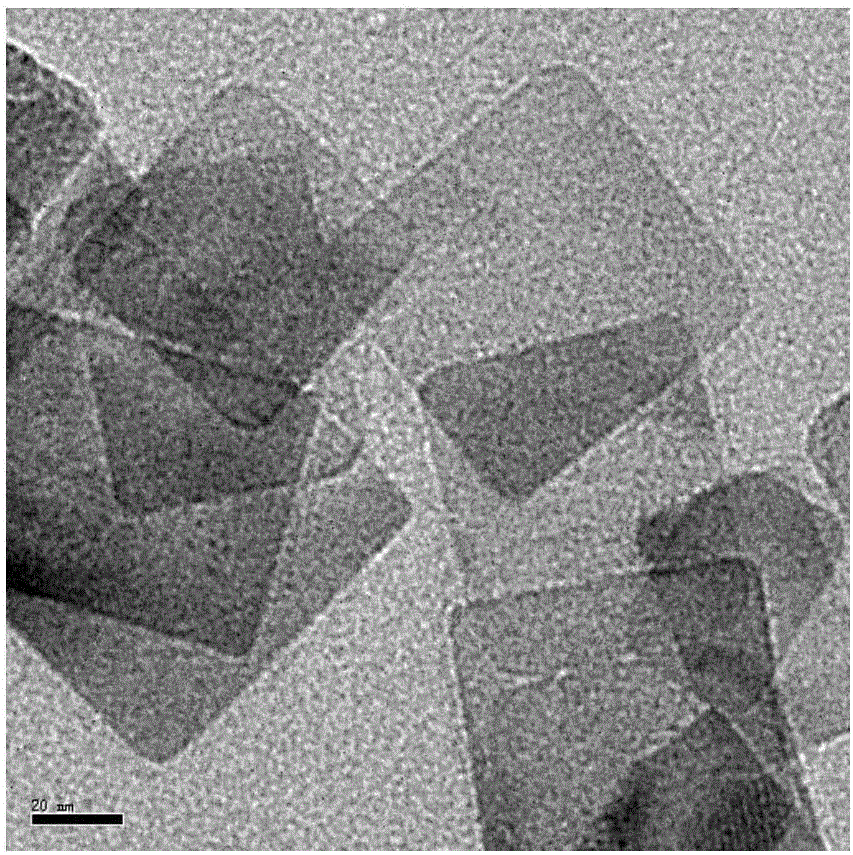

[0026] (1) 5ml of hydrofluoric acid with a mass fraction of 40% was added to 25ml of tetrabutyl titanate, stirred evenly at 25°C, put into a 100ml autoclave, and reacted at 200°C for 20 hours. After the reaction is completed, it is washed with deionized water and ethanol until neutral, and dried to obtain titanium dioxide nanosheet powder.

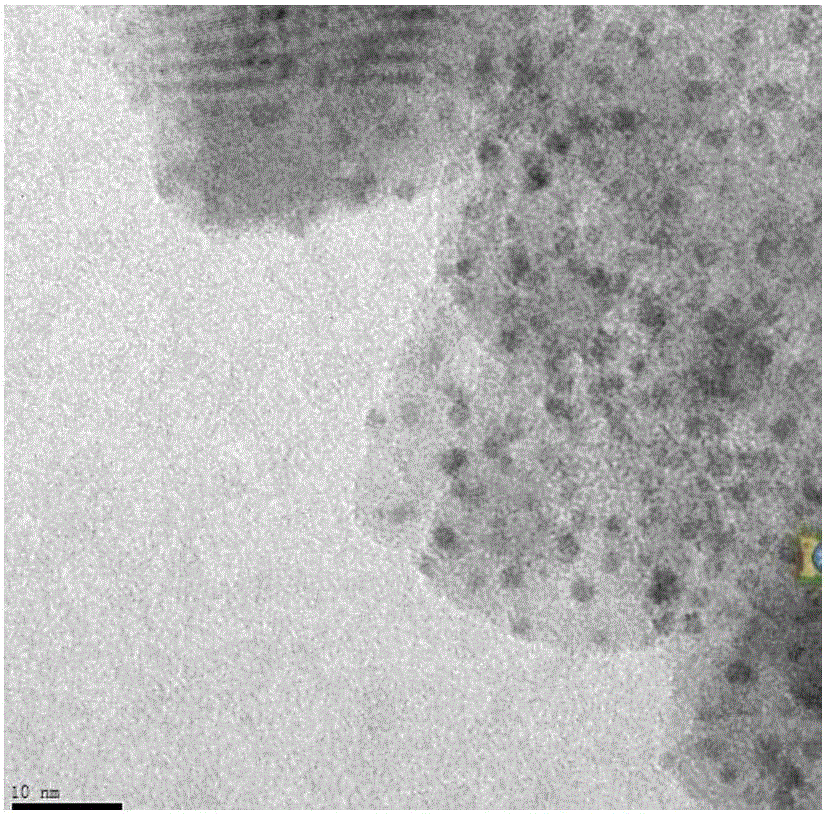

[0027] (2) Measure 10 ml of ethylene glycol in a round-bottomed flask and heat it in an oil bath at 110° C. for 30 min, then condense and reflux to remove excess water. Next, weigh 0.25 g of the prepared titanium dioxide nanosheet powder, disperse it into 5 ml of ethylene glycol and disperse it uniformly with ultrasonic waves, then add it to the above round-bottomed flask and heat at 110 °C for 30 min, and condense and reflux to remove excess water. At the same time, 0.033g of chloroplatinic acid and 0.225g of polyvinylpyrrolidone were weighed, and then added to 1ml of ethylene glycol solution respectively, ultrasonicated for 30min, and ch...

Embodiment 2

[0031] The preparation method of the highly dispersed platinum quantum dot-supported titanium dioxide nanosheet composite catalyst, the steps are the same as those in Example 1, the difference is: the mass of chloroplatinic acid used is 0.017g

[0032] Weigh 0.02 g of the titanium dioxide nanosheet-supported highly dispersed platinum quantum dot composite catalyst prepared above for the photocatalytic degradation of rhodamine B. The concentration of rhodamine B is 5 mg·L. -1 , the degradation rate of Rhodamine B was 91.0% after UV irradiation for 80 min.

Embodiment 3

[0034] The preparation method of the highly dispersed platinum quantum dot-supported titanium dioxide nanosheet composite catalyst has the same steps as those in Example 1, except that the mass of chloroplatinic acid used is 0.083 g.

[0035]Weigh 0.02 g of the titanium dioxide nanosheet-supported highly dispersed platinum quantum dot composite catalyst prepared above for the photocatalytic degradation of rhodamine B. The concentration of rhodamine B is 5 mg·L. -1 , the degradation rate of Rhodamine B was 66.4% after UV irradiation for 80 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com