Multifunctional composite film material and production process thereof

A composite membrane and multi-functional technology, applied in the field of gas purification, can solve the problems of short service life, low dust removal rate, inability to remove harmful gases, etc., and achieve the effect of long service life and efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

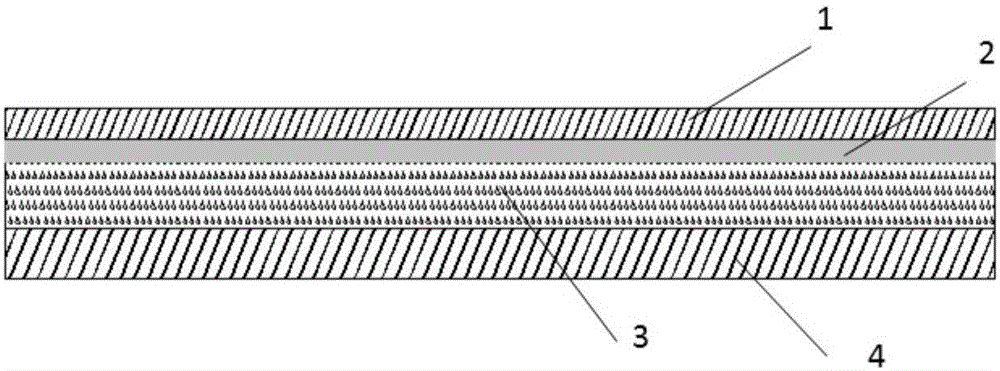

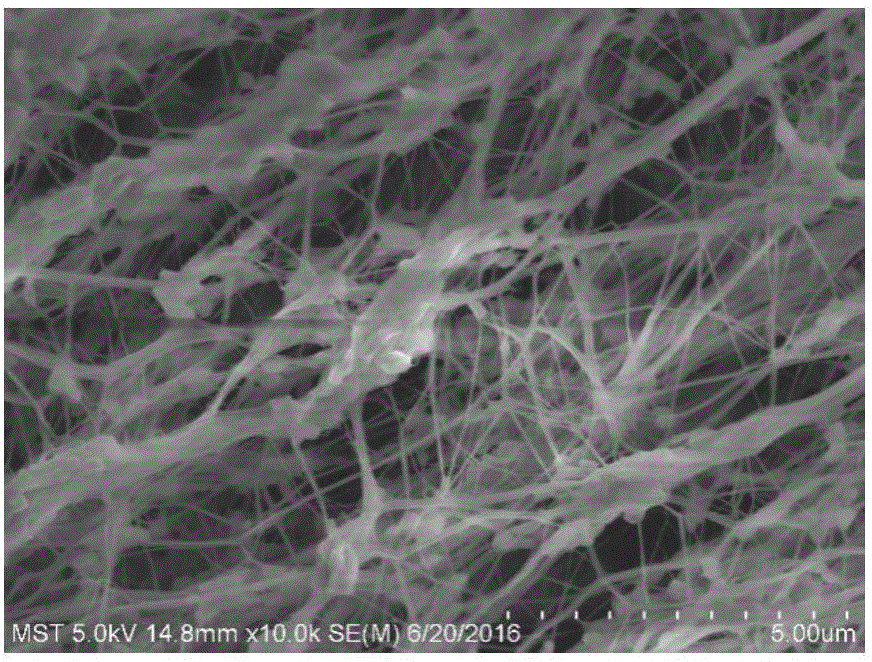

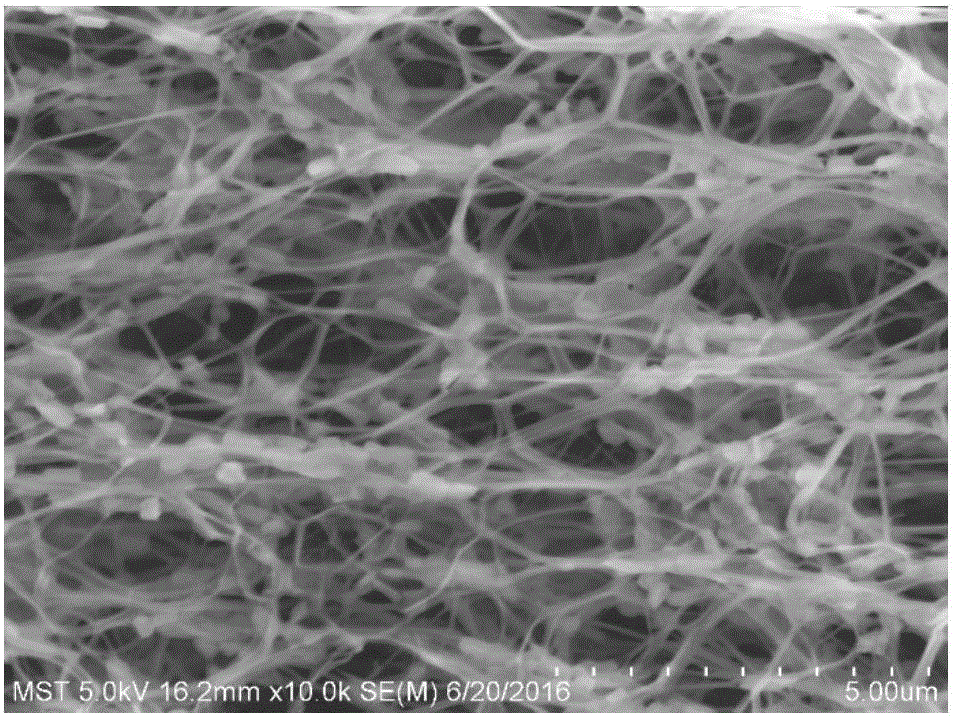

[0033] A multifunctional composite membrane material, which sequentially includes an antibacterial fiber layer, a membrane layer, a functional particle layer, and a non-woven support layer from outside to inside. The antibacterial fiber layer is prepared by mixing polyester with antibacterial material nano-silver after melting, and spinning on the surface of the membrane material by a melt-blown method. The film layer is composed of hydrophobic and oleophobic polytetrafluoroethylene porous film, which is made by depositing a layer of perfluorododecanoic acid monomolecular film on the surface of ordinary polytetrafluoroethylene film by self-assembly technology, and the oil contact angle is greater than 100°, the water contact angle is greater than 100°. The thickness of PTFE porous membrane is 0.1μm, the pore size is 5μm, and the air permeability is 10m 3 / m 2 h Pa; the thickness of the antibacterial fiber layer is 50 μm, the fiber diameter is 500 nm, and the fiber material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com