Terminal structure of super-junction MOS and manufacturing method thereof

A terminal structure and manufacturing method technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing device stability and reliability, unstable device performance, complex and cumbersome processes, etc., to improve stability, simplify structure, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

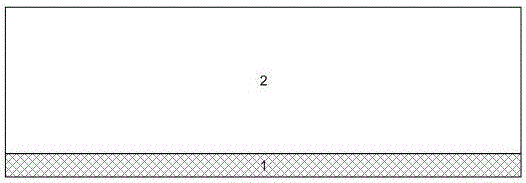

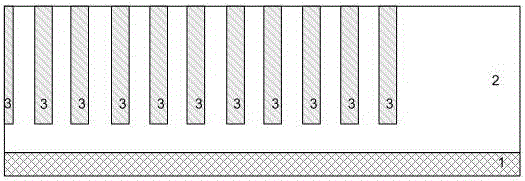

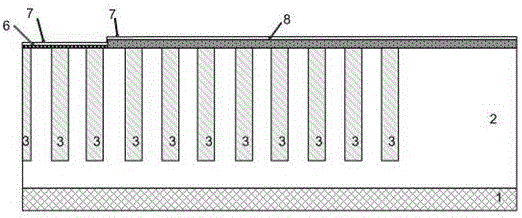

[0032] The terminal structure of a super junction MOS of the present invention includes P-type pillars and N-type pillars, wherein: a polycrystalline field plate 7 is used in the transition region from the active region to the terminal region to make the electric field distribution smoothly transition from the active region To the terminal area, the alternating structure of P-type columns and N-type columns in the terminal area is used to balance the electric field charge, wherein, the N-type epitaxial layer 2 is grown on the heavily doped N+ substrate 1, and the N-type epitaxial layer 2 An oxide layer is grown on the surface, and the trench in the active area and the trench ring in the terminal area are etched through the photolithography plate using deep groove etching. In this embodiment, the trench is a P-type trench 3, assuming that the trench width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com