Device and method for improving pulling speed of czochralski monocrystalline silicon

A technology of Czochralski single crystal and silicon pulling speed, applied in the direction of self-melt pulling method, single crystal growth, single crystal growth, etc., can solve the problem of unusable thermal field components, reduce production costs and improve safety. , the effect of increasing the axial temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

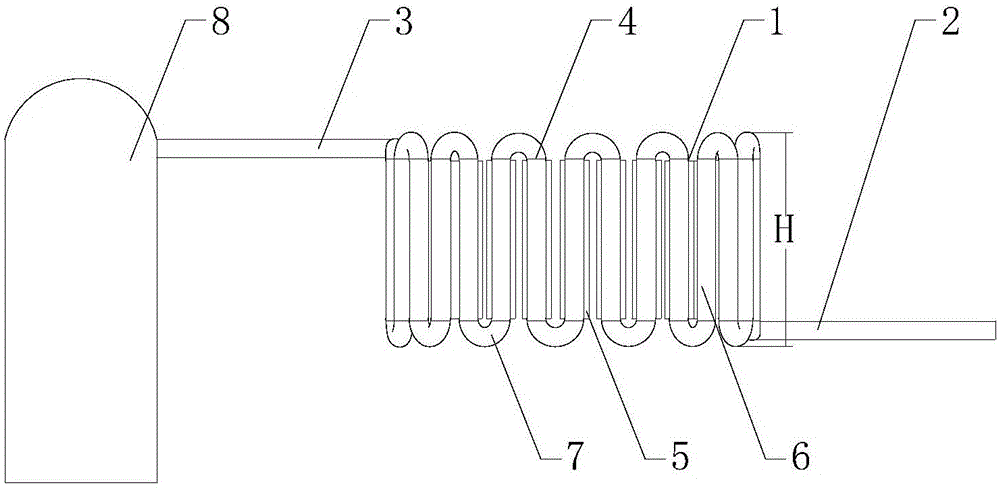

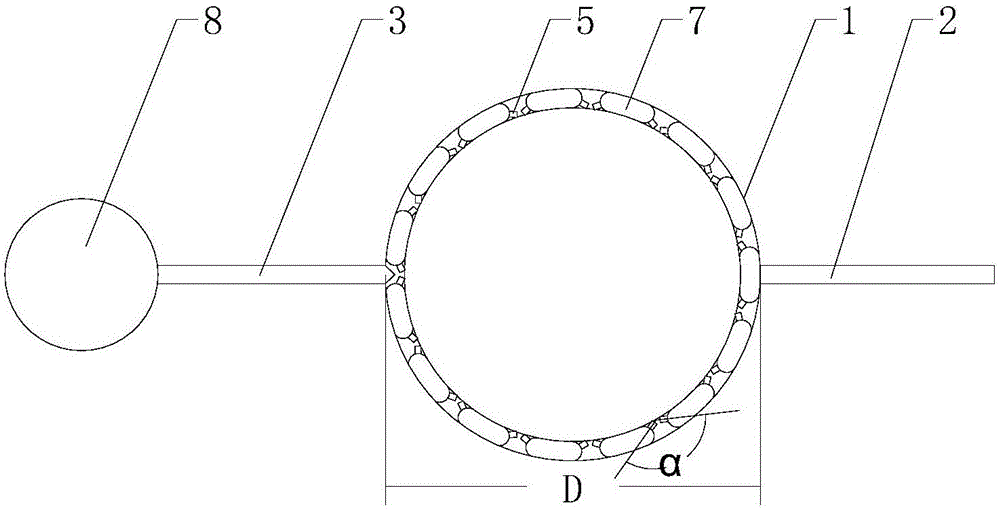

[0032] like Figure 1-2As shown, the device for improving the pulling speed of Czochralski monocrystalline silicon includes a cooling mechanism 1, a cooling medium inlet pipe 2, and a cooling medium outlet pipe 3. The cooling mechanism 1 includes a hollow cylindrical cooling body 4 and six Ten fins 5, the ratio of the height H of the cooling body 4 to the diameter D is 1:2, the cooling body 4 includes thirty sections of vertical tubes 6 and thirty sections of U-shaped tubes 7, two adjacent sections of vertical tubes 6 A section of U-shaped tube 7 is arranged between the nozzles of the tubes, and the adjacent vertical tubes 6 and U-shaped tubes 7 are connected from end to end to form a serpentine coil, and a pair of fins are symmetrically arranged on the inner and outer walls of each vertical tube 6 5. The fins 5 are high-temperature-resistant fins, and the fins 5 can increase the heat dissipation area of the cooling body 4; the angle α between the adjacent two fins 5 on each...

Embodiment 2

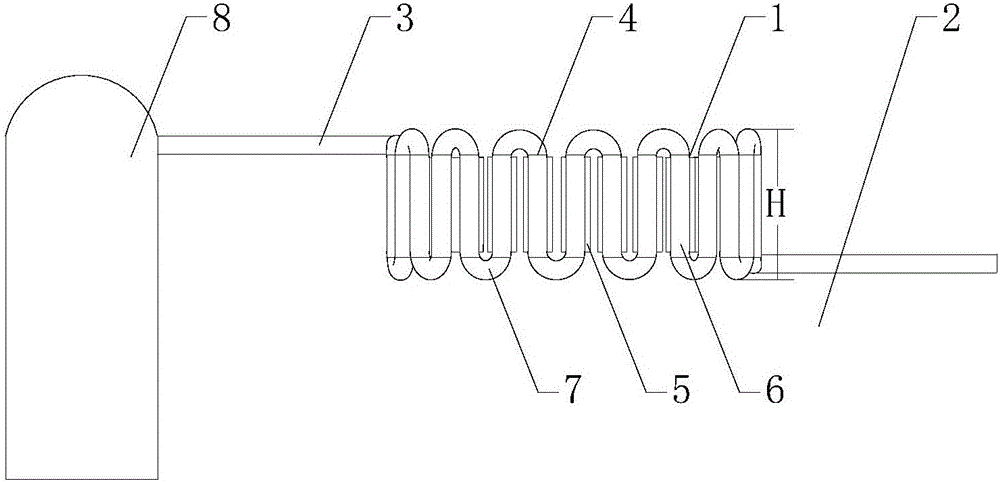

[0034] like Figure 3-4 As shown, the device for improving the pulling speed of Czochralski monocrystalline silicon includes a cooling mechanism 1, a cooling medium inlet pipe 2, and a cooling medium outlet pipe 3. The cooling mechanism 1 includes a hollow cylindrical cooling body 4 and six Ten fins 5, the ratio of the height H of the cooling body 4 to the diameter D is 1:3, the cooling body 4 includes thirty sections of vertical tubes 6 and thirty sections of U-shaped tubes 7, two adjacent sections of vertical tubes 6 A section of U-shaped tube 7 is arranged between the nozzles of the tubes, and the adjacent vertical tubes 6 and U-shaped tubes 7 are connected from end to end to form a serpentine coil, and a pair of fins are symmetrically arranged on the inner and outer walls of each vertical tube 6 5. The fins 5 are high-temperature-resistant fins 5, and the fins 5 can increase the heat dissipation area of the cooling body 4; the angle α between the adjacent two fins 5 on e...

Embodiment 3

[0036] The method for improving the pulling speed of Czochralski monocrystalline silicon carried out by using Example 1 includes the following steps: (1) preparation, (2) heating chemical material, (3) intermediate treatment, (4) equal diameter, (5) finishing and post-processing; among them,

[0037] (1) Preparation: install the cooling mechanism 1 at a place 500 mm above the monocrystalline silicon growth interface;

[0038] (2) Heating chemical material: After the preparation is completed, place the polysilicon raw material in the quartz crucible and vacuumize it, then feed argon gas into the quartz crucible so that the furnace pressure in the quartz crucible is 10torr, and wait until the furnace pressure in the quartz crucible After stabilization, start to heat the chemical material. The heating power is 70kw. While heating the material, the inert element cooling medium is delivered to the cooling mechanism 1 through the cooling medium inlet pipe 2. The delivery flow rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com