A kind of polyurethane adhesive and preparation method thereof

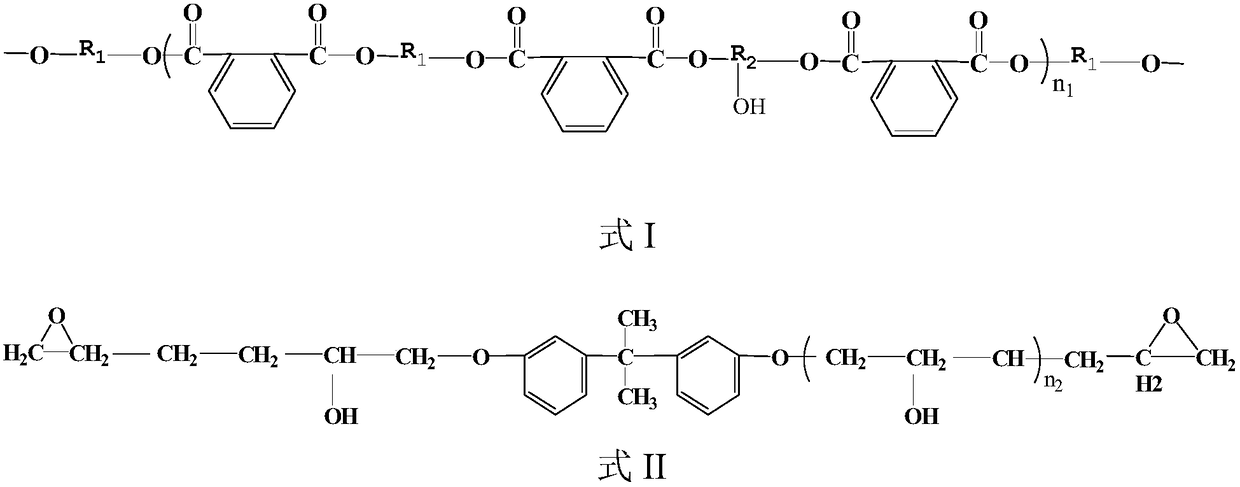

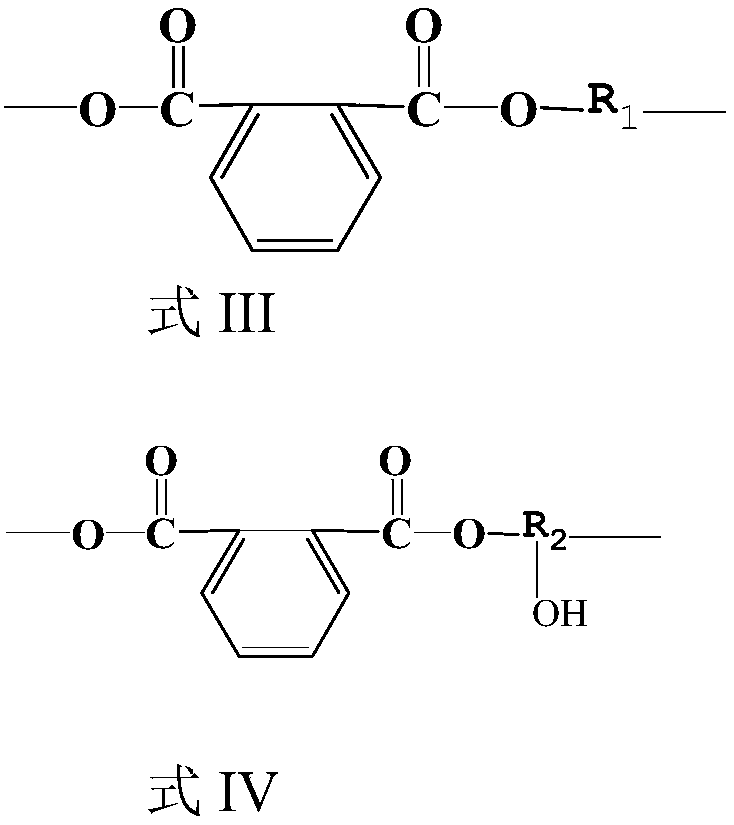

A technology of polyurethane and modified polyester, applied in the field of polyurethane, can solve the problems of poor water resistance and heat resistance, insufficient bonding strength, high density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A polyurethane adhesive for difficult-to-bond hardwoods and a preparation method thereof, mainly comprising the following steps:

[0052] (1) Preparation of castor oil modified polyester polyol

[0053] Add castor oil, phthalic anhydride, neopentyl glycol and catalyst methanesulfonic acid into a reaction kettle with nitrogen gas, use toluene to separate the generated water and polyester polyol, and perform esterification and dehydration in vacuum at 150°C for 3 hours , and then heated up to 170°C to continue the reaction for 4h, cooled and dried in a vacuum oven at 50°C to obtain a castor oil-modified polyester polyol; see Table 1 for the specific dosage of each component.

[0054] (2) Preparation of modified polyurethane adhesive

[0055] Add the obtained castor oil modified polyester polyol, polyadipate-1,4-butylene glycol ester diol with a molecular weight of 2000, and hexamethylene diisocyanate into the reaction kettle, and add the catalyst dibutyltin dilaurate Re...

Embodiment 2

[0058] A polyurethane adhesive for difficult-to-bond hardwoods and a preparation method thereof, mainly comprising the following steps:

[0059] (1) Preparation of castor oil modified polyester polyol

[0060] Add castor oil, phthalic anhydride, propylene glycol and catalyst tetra-n-butyl titanate into a reaction kettle with nitrogen gas, use butyl acetate to separate the generated water and polyester polyol, and dehydrate under vacuum at 160°C After reacting for 2 hours, raise the temperature to 210°C, keep the head temperature not lower than 100°C and react for 5h, after cooling, place it in a vacuum oven at 50°C to dry to obtain castor oil modified polyester polyol; the specific dosage of each component is detailed See Table 1.

[0061] (2) Preparation of modified polyurethane adhesive

[0062] Add the prepared castor oil modified polyester polyol, polyoxypropylene diol with a molecular weight of 2000, and toluene diisocyanate into the reaction kettle, add the catalyst di...

Embodiment 3

[0065] A polyurethane adhesive for difficult-to-bond hardwoods and a preparation method thereof, mainly comprising the following steps:

[0066] (1) Preparation of castor oil modified polyester polyol

[0067] Add castor oil, phthalic anhydride, diethylene glycol and catalyst methanesulfonic acid into a reaction kettle with nitrogen gas, use toluene to separate the generated water and polyester polyol, and perform a vacuum esterification dehydration reaction at 160°C After 2.5 hours, raise the temperature to 220°C, keep the temperature of the distillation head not lower than 100°C for 5 hours, and then place it in a vacuum oven at 50°C to dry to obtain castor oil modified polyester polyol; the specific dosage of each component is detailed See Table 1.

[0068] (2) Preparation of modified polyurethane adhesive

[0069] Add the obtained castor oil modified polyester polyol, polyethylene adipate diol with a molecular weight of 3000 and isophorone diisocyanate into the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com