Polyurethane adhesive and method for preparing same

A polyurethane and modified polyester technology, applied in the field of polyurethane, can solve the problems of poor water and heat resistance, failure to meet the needs of hardwood bonding, and insufficient bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

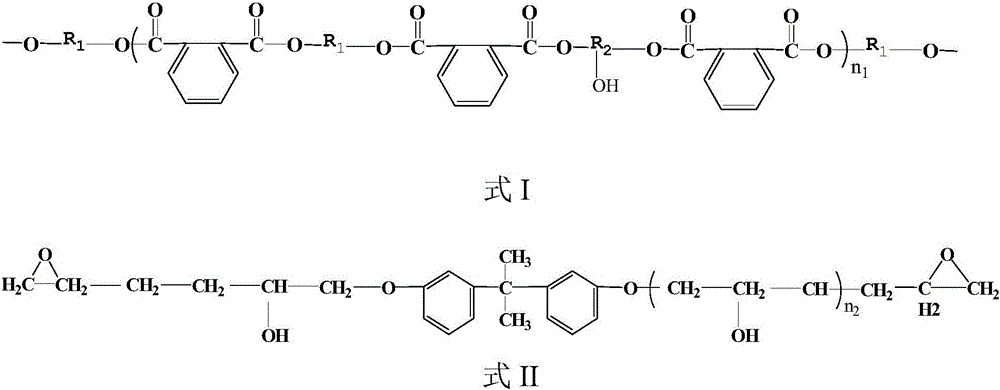

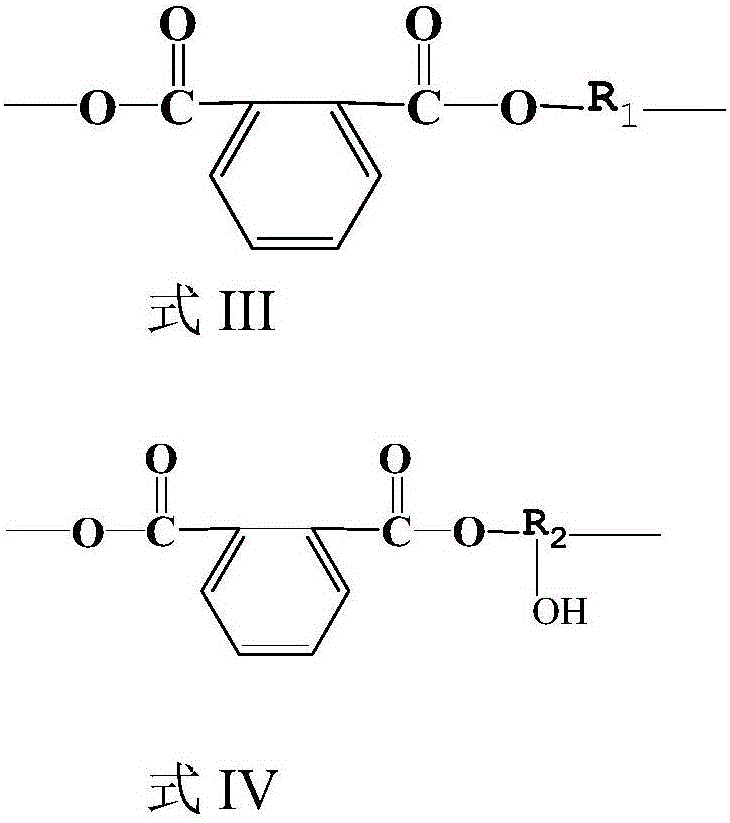

Method used

Image

Examples

Embodiment 1

[0051] A polyurethane adhesive for difficult-to-bond hardwoods and a preparation method thereof, mainly comprising the following steps:

[0052] (1) Preparation of castor oil modified polyester polyol

[0053] Add castor oil, phthalic anhydride, neopentyl glycol and catalyst methanesulfonic acid into a reaction kettle with nitrogen gas, use toluene to separate the generated water and polyester polyol, and perform esterification and dehydration in vacuum at 150°C for 3 hours , and then heated up to 170°C to continue the reaction for 4h, cooled and dried in a vacuum oven at 50°C to obtain a castor oil-modified polyester polyol; see Table 1 for the specific dosage of each component.

[0054] (2) Preparation of modified polyurethane adhesive

[0055] Add the obtained castor oil modified polyester polyol, polyadipate-1,4-butylene glycol ester diol with a molecular weight of 2000, and hexamethylene diisocyanate into the reaction kettle, and add the catalyst dibutyltin dilaurate Re...

Embodiment 2

[0058] A polyurethane adhesive for difficult-to-bond hardwoods and a preparation method thereof, mainly comprising the following steps:

[0059] (1) Preparation of castor oil modified polyester polyol

[0060] Add castor oil, phthalic anhydride, propylene glycol and catalyst tetra-n-butyl titanate into a reaction kettle with nitrogen gas, use butyl acetate to separate the generated water and polyester polyol, and dehydrate under vacuum at 160°C After reacting for 2 hours, raise the temperature to 210°C, keep the head temperature not lower than 100°C and react for 5h, after cooling, place it in a vacuum oven at 50°C to dry to obtain castor oil modified polyester polyol; the specific dosage of each component is detailed See Table 1.

[0061] (2) Preparation of modified polyurethane adhesive

[0062] Add the prepared castor oil modified polyester polyol, polyoxypropylene diol with a molecular weight of 2000, and toluene diisocyanate into the reaction kettle, add the catalyst di...

Embodiment 3

[0065] A polyurethane adhesive for difficult-to-bond hardwoods and a preparation method thereof, mainly comprising the following steps:

[0066] (1) Preparation of castor oil modified polyester polyol

[0067] Add castor oil, phthalic anhydride, diethylene glycol and catalyst methanesulfonic acid into a reaction kettle with nitrogen gas, use toluene to separate the generated water and polyester polyol, and perform a vacuum esterification dehydration reaction at 160°C After 2.5 hours, raise the temperature to 220°C, keep the temperature of the distillation head not lower than 100°C for 5 hours, and then place it in a vacuum oven at 50°C to dry to obtain castor oil modified polyester polyol; the specific dosage of each component is detailed See Table 1.

[0068] (2) Preparation of modified polyurethane adhesive

[0069] Add the obtained castor oil modified polyester polyol, polyethylene adipate diol with a molecular weight of 3000 and isophorone diisocyanate into the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com