Halogen-free flame-retardant biodegradable composite material as well as preparation method and application thereof

A composite material and biodegradable technology, which is applied in the field of halogen-free flame-retardant biodegradable composite materials and their preparation, can solve the problems of unstable organic peroxide initiators, less research on flame-retardant properties, and potential safety hazards, and achieve Good thermal stability and flame retardant performance, low price, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

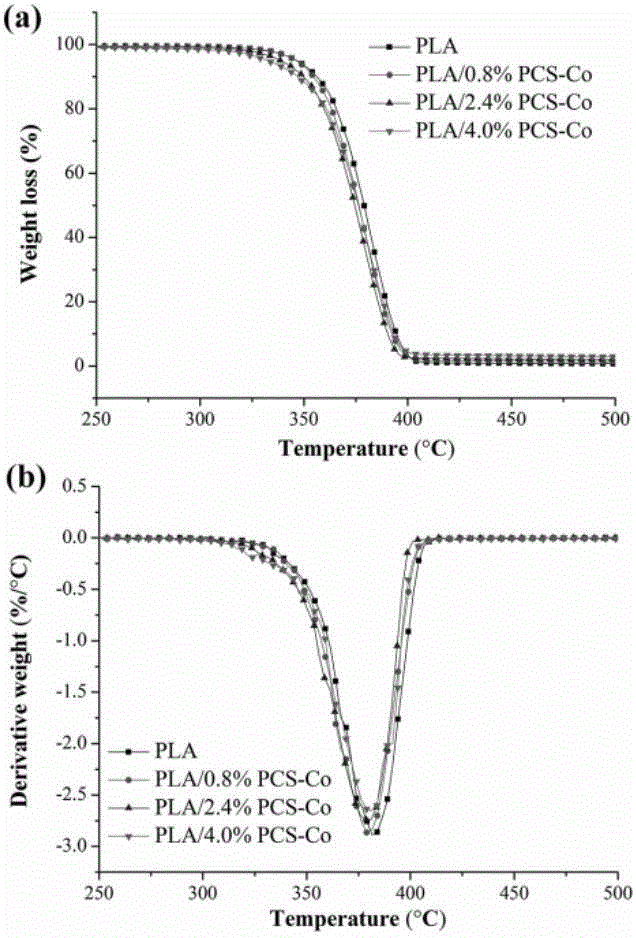

Image

Examples

Embodiment 1

[0032] Add polylactic acid (PLA) and functionalized chitosan (PCS-Co) to an internal mixer at a temperature of 180°C and a rotor speed of 45r / min according to the following mass ratio and mix for 8 minutes, and mix well to obtain blue shades Cured products with different degrees, that is, halogen-free flame-retardant biodegradable composite materials. The specific mass between functionalized chitosan and polylactic acid is shown in Table 1.

[0033] Wherein, the specific preparation steps of PCS-Co are as follows:

[0034] (1) Preparation of phosphated chitosan: Dissolve 4g of chitosan in 60ml of methanesulfonic acid, add 20g of phosphorus pentoxide after complete dissolution, react under nitrogen protection, and control it in an ice-water bath at 0°C for 3 Hour. The product after the reaction was washed with ether, acetone, and methanol respectively, and a white powder was obtained after suction filtration in a suction filtration machine. Then, put the white powder into a ...

Embodiment 2

[0039] Add polylactic acid (PLA) and functionalized chitosan (PCS-Fe) with a specific mass ratio (specific mass such as Example 1) to a banbury mixer with a temperature of 180°C and a rotor speed of 40r / min for 10min , to obtain a cured product after mixing evenly, that is, a halogen-free flame-retardant biodegradable composite material.

[0040] Wherein, the specific preparation steps of PCS-Fe are as follows:

[0041] (1) Preparation of phosphated chitosan: Dissolve 4g of chitosan in 60ml of methanesulfonic acid, add 36g of phosphorus pentoxide after complete dissolution, react under nitrogen protection, and control it in an ice-water bath at 5°C for 8 Hour. The product after the reaction was washed with ether, acetone, and methanol respectively, and a white powder was obtained after suction filtration in a suction filtration machine. Then, put the white powder into a vacuum drying oven and dry for 24 hours to obtain the intermediate product phosphorylated chitosan.

[00...

Embodiment 3

[0044] Polybutylene succinate ( PBS) and functionalized chitosan (PCS-Co, specific preparation steps such as embodiment 1) are joined in the internal mixer that temperature is 120 ℃, rotor speed is 45r / min banburying 8min, after mixing uniformly, obtain cured product, That is, halogen-free flame-retardant biodegradable composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com