Method for producing foam material in rubber mold and sole material produced by method

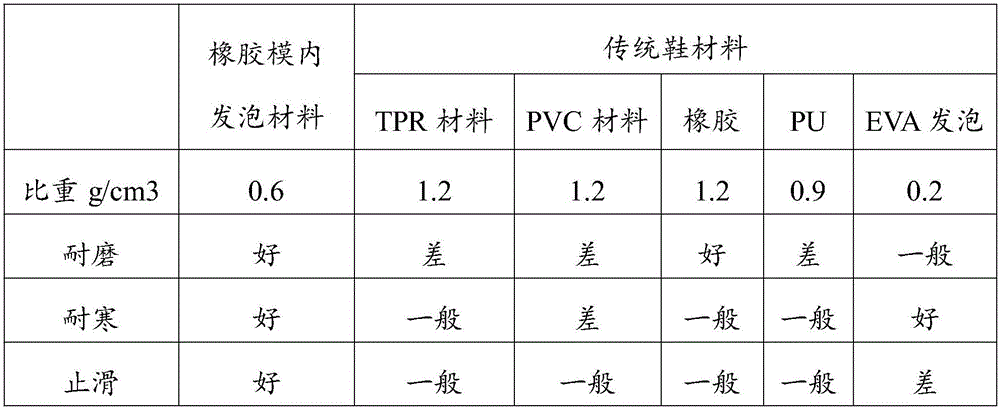

A foaming material and processing method technology, which is applied to the processing field of shoe sole material and rubber in-mold foaming material, can solve the problems of heavy quality, poor wear resistance and long cooling time of ordinary shoe materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The concrete processing method of the present embodiment is as follows:

[0046] (1) Preparation of oil-extended glue:

[0047] Styrene-Butadiene-Styrene Block Copolymer

80g

naphthenic oil

50g

mixing temperature

40℃

mixing time

3 hours

[0048] (2) Preparation of hard material:

[0049] Oil-extended glue

130g

20g

K resin

25g

Polyphenylene ether

20g

Melting section temperature

180℃

[0050] (3) Preparation of soft material:

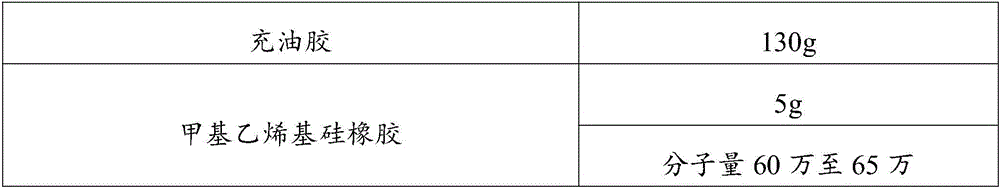

[0051]

[0052]

[0053] (4) Mechanically mix the hard material and the soft material according to the weight ratio of 1:2 to obtain the rubber in-mold foaming material. The obtained rubber in-mold foam material was used as a shoe sole material.

Embodiment 2

[0055] The concrete processing method of the present embodiment is as follows:

[0056] (1) Preparation of oil-extended glue:

[0057] Styrene-Butadiene-Styrene Block Copolymer

50g

20g

mixing temperature

80℃

mixing time

3 hours

[0058] (2) Preparation of hard material:

[0059] Oil-extended glue

70g

30g

K resin

26g

Polyphenylene ether

5g

10g

Melting section temperature

280℃

[0060] (3) Preparation of soft material:

[0061]

[0062]

[0063] (4) Mechanically mix the hard material and the soft material according to the weight ratio of 2:1 to obtain the rubber in-mold foaming material. The obtained rubber in-mold foam material was used as a shoe sole material.

Embodiment 3

[0065] The concrete processing method of the present embodiment is as follows:

[0066] (1) Preparation of oil-extended glue:

[0067] Styrene-Butadiene-Styrene Block Copolymer

75g

naphthenic oil

45g

mixing temperature

50℃

mixing time

2 hours

[0068] (2) Preparation of hard material:

[0069] Oil-extended glue

120g

polystyrene

22g

K resin

24g

Polyphenylene ether

15g

2g

Melting section temperature

200℃

[0070] (3) Preparation of soft material:

[0071]

[0072] (4) Mechanically mix the hard material and the soft material according to the weight ratio of 1:1 to obtain the rubber in-mold foaming material. The obtained rubber in-mold foam material was used as a shoe sole material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com