A kind of compound foliage fertilizer and its preparation method and application

A foliar fertilizer and compound technology, applied in the fields of agriculture and compound fertilizers, can solve the problems of endangering the health and safety of humans and animals, easy to directly enter the water body, destroying the ecological balance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

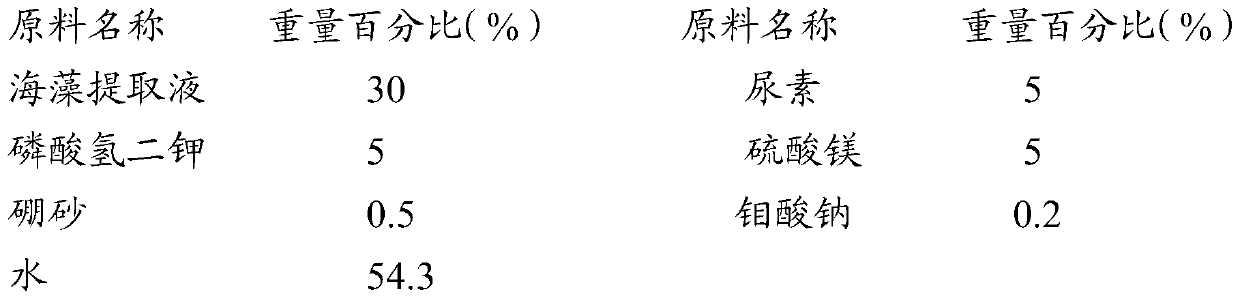

[0034] Example 1 A compound foliar fertilizer

[0035] The raw material composition is:

[0036]

[0037] Prepared by:

[0038] Add 300 kg of seaweed extract, 50 kg of urea, 50 kg of dipotassium hydrogen phosphate, 50 kg of magnesium sulfate, 5 kg of borax, and 2 kg of sodium molybdate into 543 kg of water, heat up to 20°C, and mix with a high-speed homogenizer for 1 Hour, the homogeneous and stable suspension that obtains is the target product of this embodiment.

[0039] Wherein, the seaweed extract is prepared by the following method:

[0040] 1) Cut 1,000 kg of fresh Sargassum to 5-10 cm, and pass through a colloid mill for 2 minutes;

[0041] 2) Add 1000 kg of water to the Sargassum obtained in step 1), then add 1 kg of alginate lyase, and enzymolyze it at 35°C for 2 hours with stirring to obtain a mixed solution;

[0042] 3) Cool the mixed solution obtained in step 2) to normal temperature, centrifuge at a speed of 3000 rpm, separate for 30 minutes, and separate...

Embodiment 2

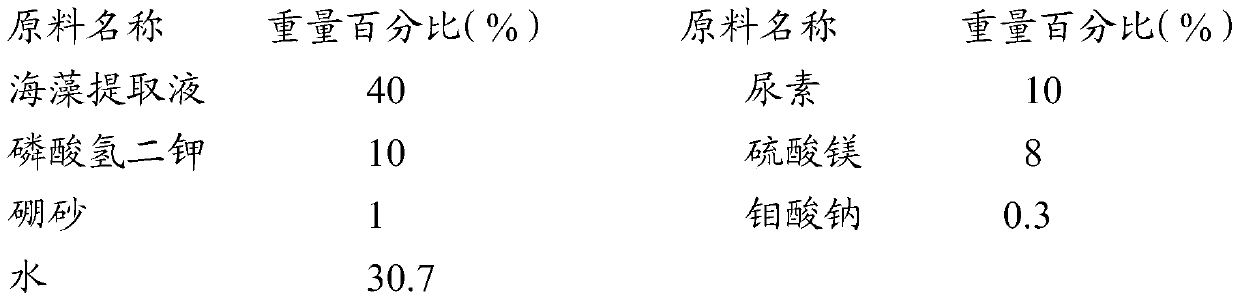

[0044] Example 2 A compound foliar fertilizer

[0045] Raw material composition:

[0046]

[0047] Prepared by:

[0048] Add 400 kg of seaweed extract, 100 kg of urea, 100 kg of dipotassium hydrogen phosphate, 80 kg of magnesium sulfate, 10 kg of borax, and 3 kg of sodium molybdate into 307 kg of water, heat up to 30°C, and mix in a high-speed homogenizer After 2 hours, the obtained uniform and stable suspension is the target product of this embodiment.

[0049] The seaweed extract wherein is prepared by the following method:

[0050] 1) Cut 1,000 kg of fresh kelp to 5-10 cm, and pass it through a colloid mill for 2 minutes;

[0051] 2) Add 1000 kg of water to the kelp obtained in step 1), then add 1.2 kg of alginate lyase, stir and enzymolyze at 40°C for 4 hours to obtain a mixed solution;

[0052] 3) Cool the mixed solution obtained in step 2) to normal temperature, centrifuge at a speed of 3000 rpm, separate for 30 minutes, and separate the supernatant and the preci...

Embodiment 3

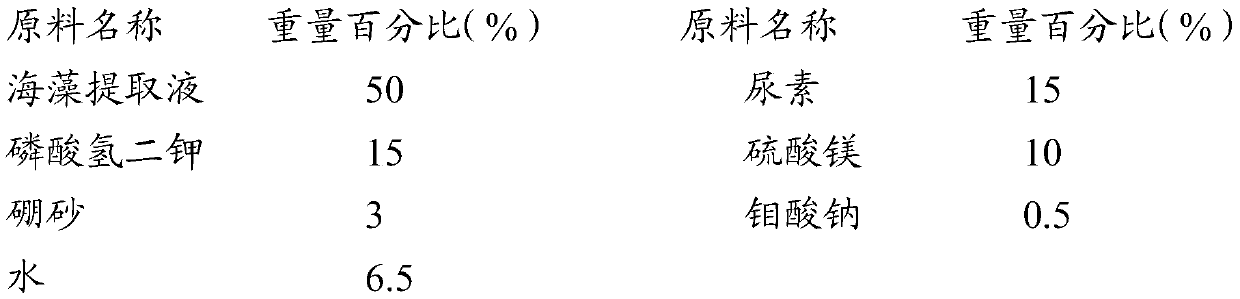

[0054] Example 3 A compound foliar fertilizer

[0055] Raw material composition:

[0056]

[0057] Prepared by:

[0058] Add 500 kg of seaweed extract, 150 kg of urea, 150 kg of dipotassium hydrogen phosphate, 100 kg of magnesium sulfate, 30 kg of borax, and 5 kg of sodium molybdate into 65 kg of water, heat up to 40°C, and mix in a high-speed homogenizer After 3 hours, the obtained uniform and stable suspension was the target product of this embodiment.

[0059] Wherein, the raw seaweed extract is prepared by the following method:

[0060] 1) Cut 1,000 kg of fresh wakame to 5-10 cm, and pass it through a colloid mill for 2 minutes;

[0061] 2) Add 1000 kg of water to the fresh wakame obtained in step 1), then add 1.4 kg of alginate lyase, stir and enzymolyze at 45°C for 5 hours to obtain a mixed solution;

[0062] 3) Cool the mixed solution obtained in step 2) to normal temperature, centrifuge at a speed of 3000 rpm, separate for 30 minutes, and separate the superna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com