Composite leaf fertilizer and preparing method and application thereof

A foliar fertilizer and compound technology, which is applied in the field of agriculture and compound fertilizers, can solve the problems of endangering the health and safety of humans and animals, destroying ecological balance, and easily entering water bodies directly, so as to speed up the growth and development of plants, improve the quality, and have outstanding environmental protection performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

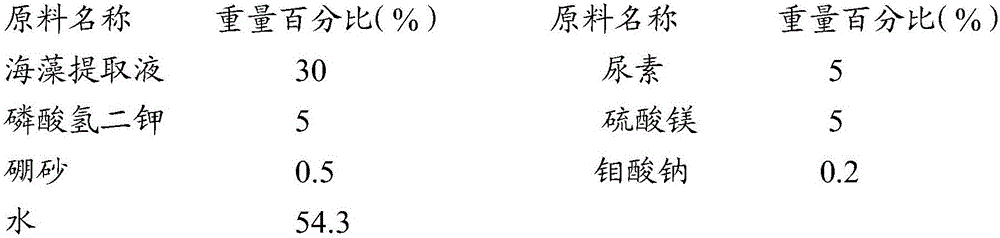

[0034] Example 1 A compound foliar fertilizer

[0035] The composition of raw materials is:

[0036]

[0037] Prepared by:

[0038] 300 kg of seaweed extract, 50 kg of urea, 50 kg of dipotassium hydrogen phosphate, 50 kg of magnesium sulfate, 5 kg of borax, and 2 kg of sodium molybdate were added to 543 kg of water, heated to 20°C, and mixed with a high-speed homogenizer for 1 hour, the obtained uniform and stable suspension is the target product of this example.

[0039] Wherein, the seaweed extract is prepared by the following method:

[0040] 1) Cut 1000 kilograms of fresh Sargassum to 5~10cm, and pass through colloid mill for 2 minutes;

[0041] 2) adding 1000 kilograms of water to the sargassum obtained in step 1), then adding 1 kilogram of alginate lyase, and enzymolysis for 2 hours under stirring at 35°C to obtain a mixed solution;

[0042] 3) cooling the mixed solution obtained in step 2) to normal temperature, centrifuging, rotating speed 3000 rev / Min, separa...

Embodiment 2

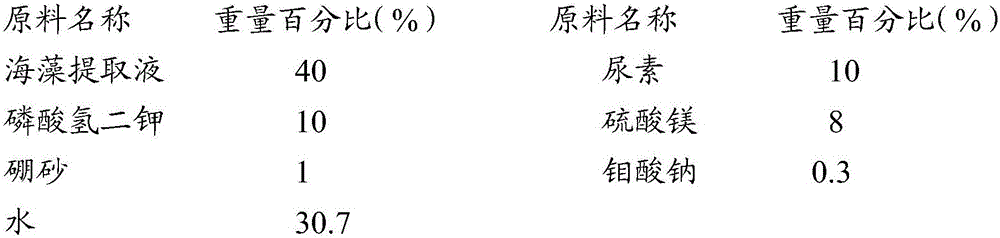

[0044] Example 2 A compound foliar fertilizer

[0045] Raw material composition:

[0046]

[0047] Prepared by:

[0048] 400 kg of seaweed extract, 100 kg of urea, 100 kg of dipotassium hydrogen phosphate, 80 kg of magnesium sulfate, 10 kg of borax, and 3 kg of sodium molybdate were added to 307 kg of water, heated to 30°C, and mixed in a high-speed homogenizer After 2 hours, the obtained uniform and stable suspension is the target product of this example.

[0049] The described seaweed extract wherein is prepared by the following method:

[0050] 1) Cut 1000 kilograms of fresh kelp to 5-10 cm, and pass the colloid mill for 2 minutes;

[0051] 2) adding the kelp obtained in step 1) to 1000 kilograms of water, then adding 1.2 kilograms of alginate lyase, and stirring the enzymolysis for 4 hours at 40°C to obtain a mixed solution;

[0052] 3) the mixed solution obtained in step 2) was cooled to normal temperature, centrifuged at 3000 rev / Min, and separated for 30 minutes...

Embodiment 3

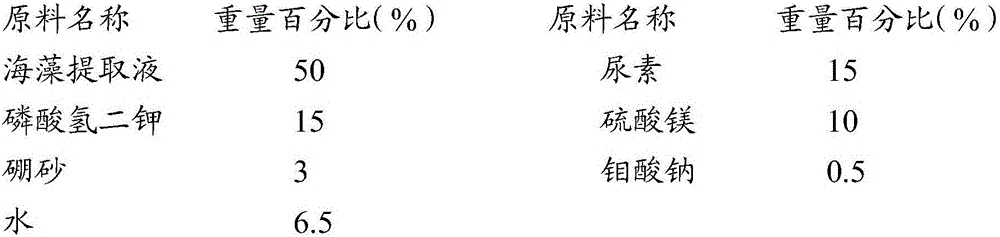

[0054] Example 3 A compound foliar fertilizer

[0055] Raw material composition:

[0056]

[0057] Prepared by:

[0058] 500 kg of seaweed extract, 150 kg of urea, 150 kg of dipotassium hydrogen phosphate, 100 kg of magnesium sulfate, 30 kg of borax, and 5 kg of sodium molybdate were added to 65 kg of water, heated to 40°C, and mixed in a high-speed homogenizer After 3 hours, the obtained uniform and stable suspension is the target product of this example.

[0059] Wherein, the raw material seaweed extract is prepared by the following method:

[0060] 1) Cut 1000 kg of fresh wakame to 5-10 cm, and pass through a colloid mill for 2 minutes;

[0061] 2) adding 1000 kilograms of water to the fresh wakame obtained in step 1), then adding 1.4 kilograms of alginate lyase, and stirring enzymolysis for 5 hours at 45°C to obtain a mixed solution;

[0062] 3) the mixed solution obtained in step 2) was cooled to normal temperature, centrifuged at 3000 rev / Min, and separated for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com