High slump loss resistant concrete water reducer and preparation method thereof

A concrete water reducer, high slump retention technology, applied in the field of concrete admixtures, can solve the problems of unsatisfactory high-performance concrete, poor slump retention capacity, single component of water reducer, etc., to overcome large slump loss , Strong slump retention ability, high early strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

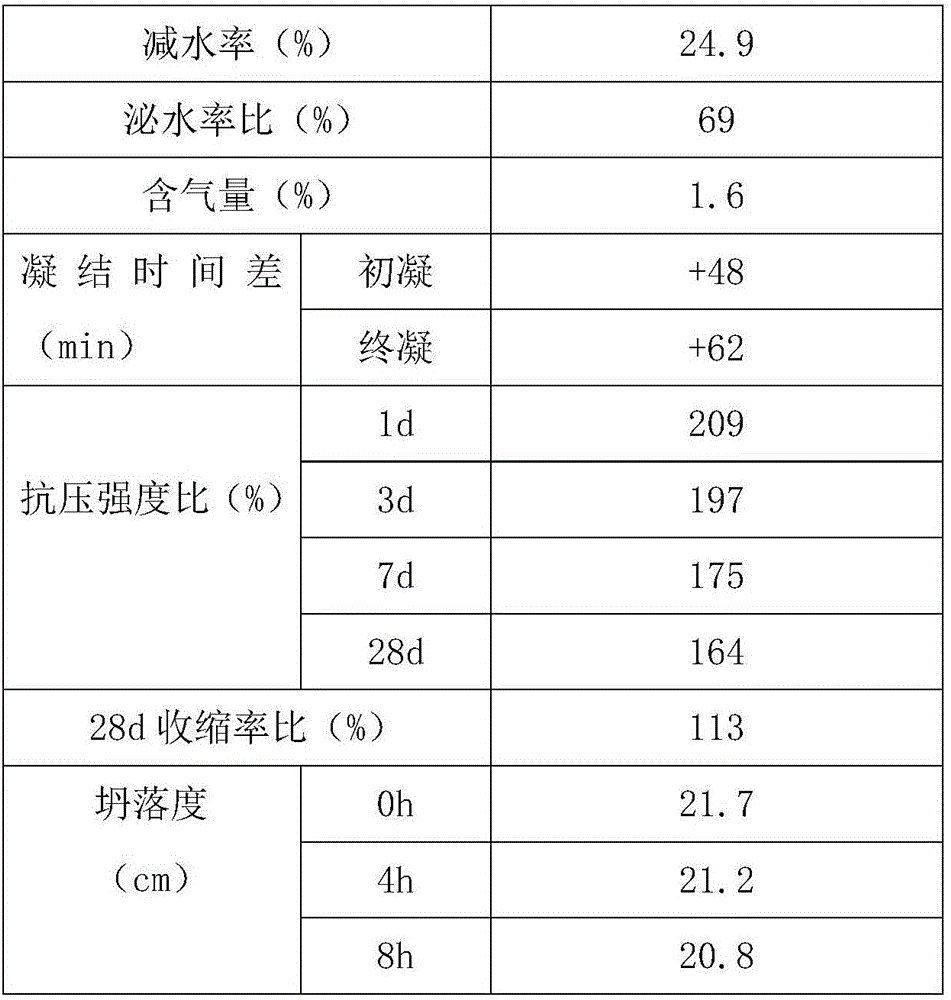

[0012] A high slump-retaining concrete water-reducing agent, which is composed of the following raw materials by weight (kg): aliphatic hydroxysulfonate condensate 11, β-naphthalenesulfonate sodium formaldehyde condensate 9, sulfonated phenolic resin 7, casein 4.5 , MPEGMA-MA-SMAS terpolymer 8, ammonium alginate 6, potassium humate 10, calcium chloride 6, sodium hydroxypropyl starch succinate 8, sodium dodecylbenzenesulfonate 4.5.

[0013] A preparation method of high slump-retaining concrete water reducer, comprising the following steps:

[0014] (1) Mix the aliphatic hydroxysulfonate condensate, β-naphthalenesulfonate sodium formaldehyde condensate, sulfonated phenolic resin, and MPEGMA-MA-SMAS terpolymer evenly, and then add it to the ball mill to control the ball-to-material ratio to 4:1, the speed is 500r / min, dry ball milling for 7h, then add sodium hydroxypropyl oxidized starch succinate, sodium dodecylbenzenesulfonate, potassium humate, control the ratio of ball to mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com