Treatment method of berberine hydrochloride containing waste water

A technology of berberine hydrochloride and its treatment method, which is applied in the field of treatment of berberine hydrochloride wastewater, can solve the problems of difficult to achieve high-efficiency treatment effect, pollution of berberine hydrochloride wastewater, low efficiency, etc., to save manpower, reduce pollution load and Toxic, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

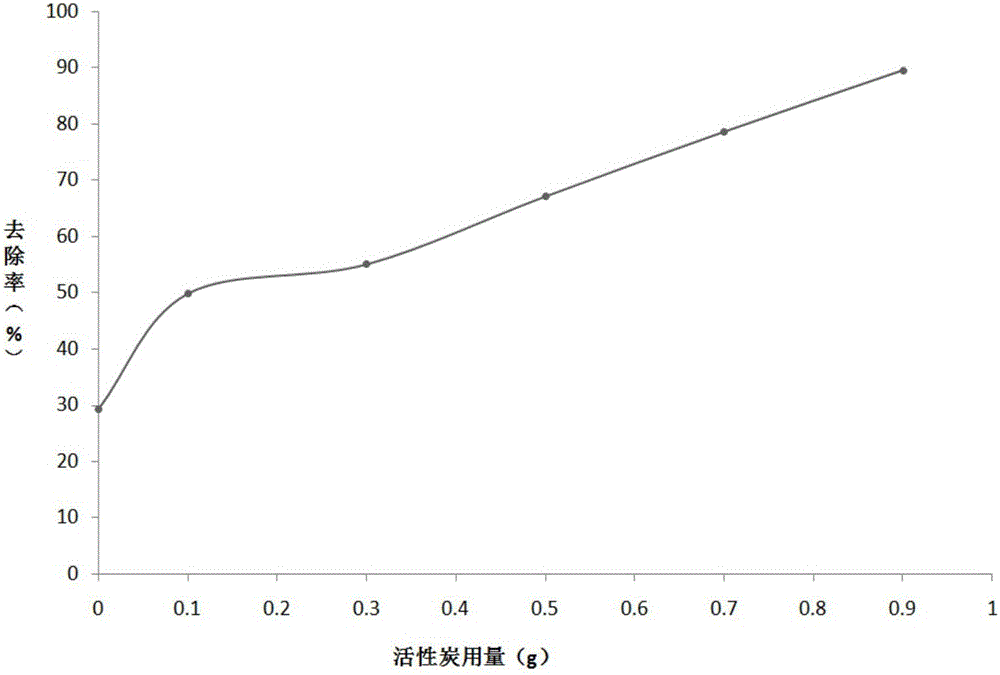

[0025] Get concentration and be the berberine hydrochloride solution 50mL of 800mg / L in 100mL Erlenmeyer flask, in Fe 2+ 0.41g, H 2 o 2 Under the condition of 0.6mol / L, add 0g, 0.1g, 0.3g, 0.5g, 0.7g, 0.9g of activated carbon respectively, set the microwave power to 700W, and microwave time to 5min to make it fully react. After the reaction, the flask was taken out, centrifuged, and cooled to room temperature. The result is as figure 1 .

[0026] With the increase of the amount of activated carbon, the removal rate of berberine hydrochloride gradually increased. When the amount of activated carbon was 0.1g, the removal rate of berberine hydrochloride was only 47.95%. When the amount of activated carbon increased to 0.7g, the removal rate of berberine hydrochloride reached 89.48%. %.

Embodiment 2

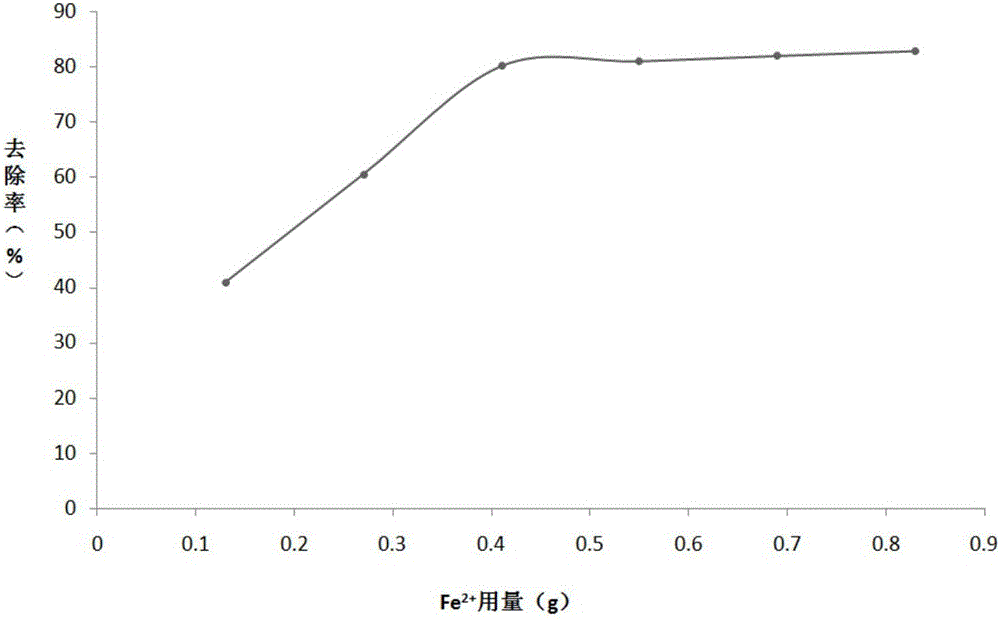

[0028] Get the berberine hydrochloride solution 50mL that concentration is 800mg / L in 100mL Erlenmeyer flask, in H 2 o 2 0.6mol / L and 0.7g of activated carbon, Fe 2+ 0.13g, 0.27g, 0.41g, 0.55g, 0.69g, 0.83g, set the microwave power to 700W, and the microwave time to 5min to make it fully react. After the microwave is over, take out the Erlenmeyer flask, cool to room temperature, centrifuge, and measure the filtrate content of berberine hydrochloride. The result is as figure 2 .

[0029] With Fe 2+ With the increasing dosage, the removal rate of berberine hydrochloride gradually increased. The removal rate decreases slowly at 0.55. When Fe 2+ When the dosage is 0.41g, the removal rate is the highest, reaching 80.17%.

Embodiment 3

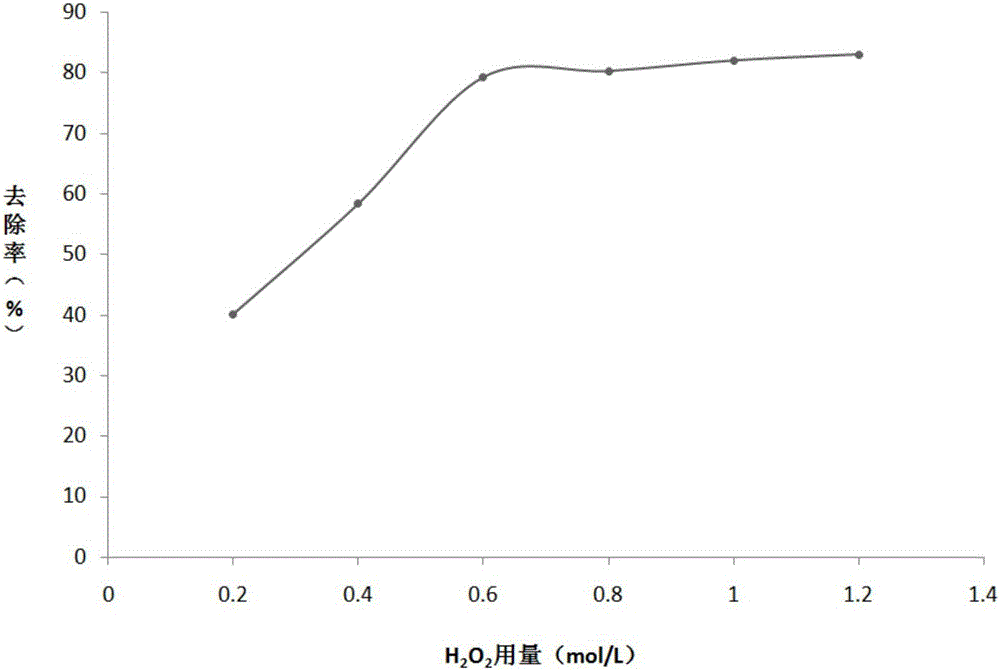

[0031] Get concentration and be the berberine hydrochloride solution 50mL of 800mg / L in 100mL Erlenmeyer flask, in Fe 2+ 0.41g, activated carbon 0.7g, add H 2 o 2 0.2mol / L, 0.4mol / L, 0.6mol / L, 0.8mol / L, 1mol / L, 1.2mol / L, set the microwave power to 700W, and the microwave time to 5min to make it fully react. After the microwave was finished, the Erlenmeyer flask was taken out, cooled to room temperature, centrifuged, and the content of berberine hydrochloride in the filtrate was determined. The result is as image 3 .

[0032] With H 2 o 2 With the increasing dosage, the removal rate of berberine hydrochloride increased. It tends to be flat at 0.8mol / L. When H 2 o 2 When the dosage is 0.6mol / L, the removal rate is 79.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com