Forming mold for foamed cement board and method for preparing foamed cement board

A foamed cement board and forming mold technology, which is applied in the field of building materials processing, can solve the problems of thickness control and temperature control of foamed cement products, and achieve the effects of simple structure, product quality assurance, and accelerated curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

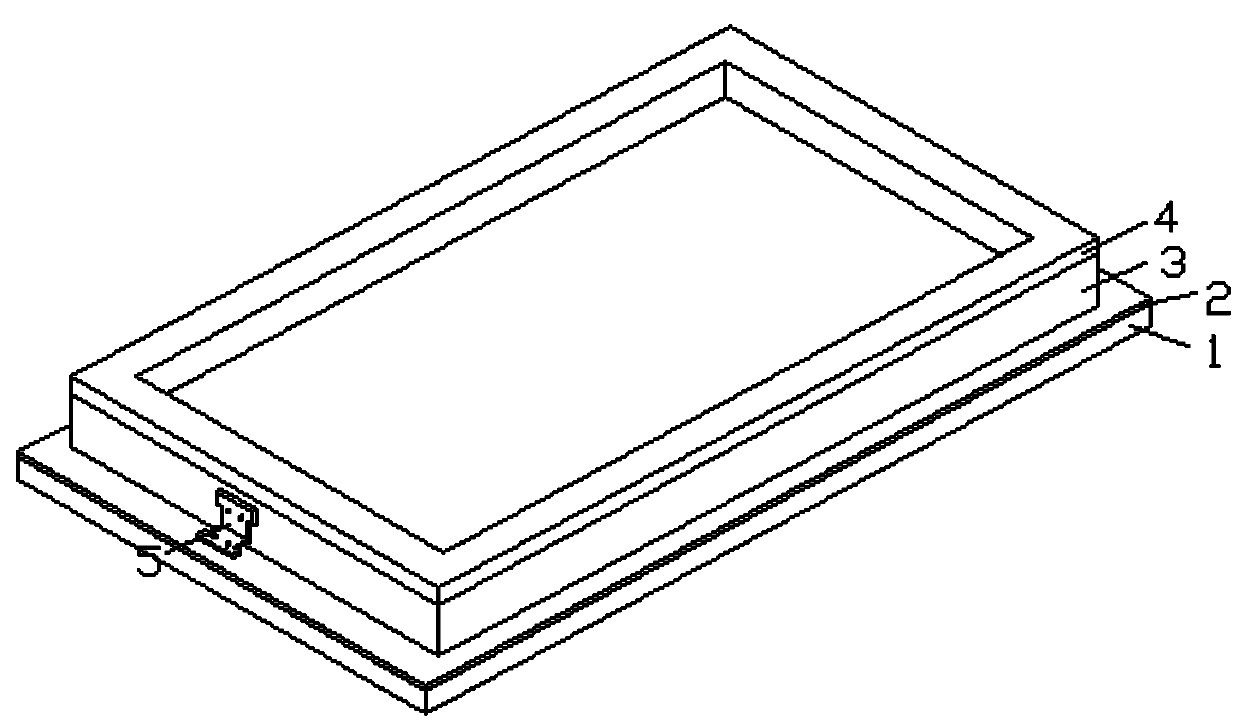

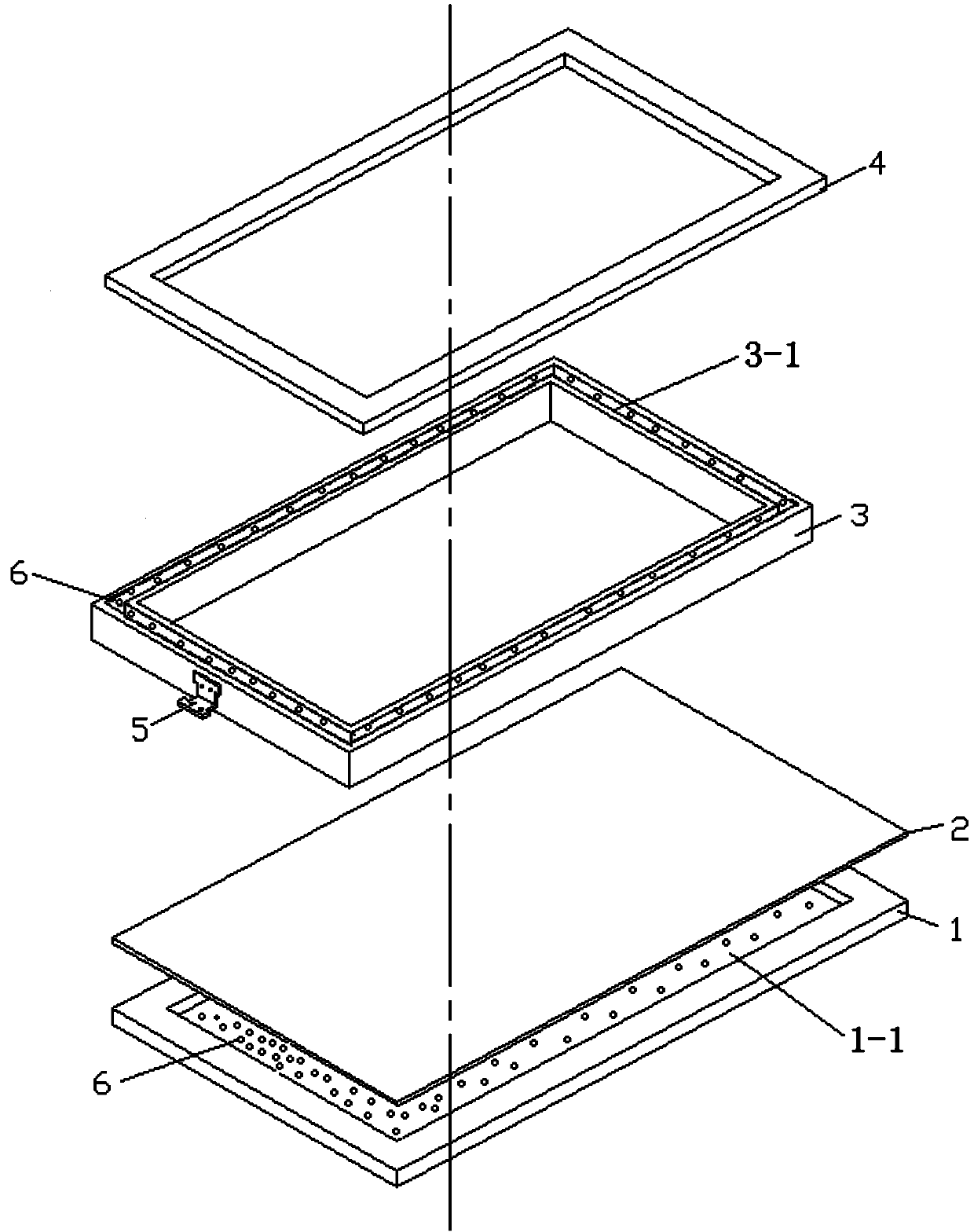

[0036] The materials for preparing the bottom mold (1), bottom mold cover (2), side molds (3), side mold covers (4) and connectors (5) can be metal, metal alloy, engineering plastics, and are not limited to this.

[0037] A method for preparing foamed cement boards with a foamed cement board molding die, comprising the following steps:

[0038] 1. Select the appropriate phase change material;

[0039] 2. Fill the bottom mold cavity of the bottom mold and the side mold cavity of the side mold with phase change material, cover the bottom mold on the bottom mold, and cover the side mold on the side mold, and package them;

[0040] 3. Install the side mold on the base of the forming mold through the connecting piece;

[0041] 4. Stir the foamed cement well, pour it into the mold, and let it stand for foaming;

[0042] 5. After curing at room temperature or microwave for a certain age, the formwork is removed, the foamed cement is cut to make foamed cement boards, inspected, pac...

Embodiment 1

[0049] Embodiment 1: A method for preparing foamed cement board by a foamed cement board forming mold

[0050] 1. Select inorganic phase change heat storage materials.

[0051] 2. Fill the bottom mold cavity (1-1) of the bottom mold (1) with the preferred phase change material, and connect the bottom mold (1) and the bottom mold cover (2) by bolts to form the base of the foamed cement board mold ; Fill the side mold cavity (3-1) of the side mold (3) with the preferred phase change material, select the number of side molds (3) matching the thickness of the foamed cement board, and connect the side molds ( 3) and the side mold cover (4), forming the frame of the foamed cement board mould;

[0052] 3. Install the side mold on the bottom mold through the connecting piece (5);

[0053] 4. Stir according to the weight ratio of 500 parts of Portland cement, 20 parts of foaming agent hydrogen peroxide, 2.5 parts of foam stabilizer fatty acid methanol amide, 5 parts of potassium sili...

Embodiment 2

[0055] Embodiment 2: A method for preparing foamed cement board by a foamed cement board forming mold

[0056] 1. Select organic phase change heat storage materials.

[0057] 2. Fill the bottom mold cavity (1-1) of the bottom mold (1) with the preferred phase change material, and connect the bottom mold (1) and the bottom mold cover (2) by bolts to form the base of the foamed cement board mold ; Fill the side mold cavity (3-1) of the side mold (3) with the preferred phase change material, select the number of side molds (3) matching the thickness of the foamed cement board, and connect the side molds ( 3) and the side mold cover (4), forming the frame of the foamed cement board mould;

[0058] 3. Install the side mold on the bottom mold through the connecting piece (5);

[0059]4. According to 500 parts of Portland cement, 50 parts of foaming agent hydrogen peroxide, 5 parts of foam stabilizer fatty acid methanol amide, 5 parts of foam stabilizer ethylenediaminetetraacetic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com