New application of polyvinylamine, perovskite thin film, perovskite solar cell and fabrication method of perovskite solar cell

A solar cell and polyvinylamine technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficulty in obtaining continuous dense and consistent films, charge and energy loss, and battery efficiency decline, and achieve long-term stability , Inhibit interface recombination and reduce charge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

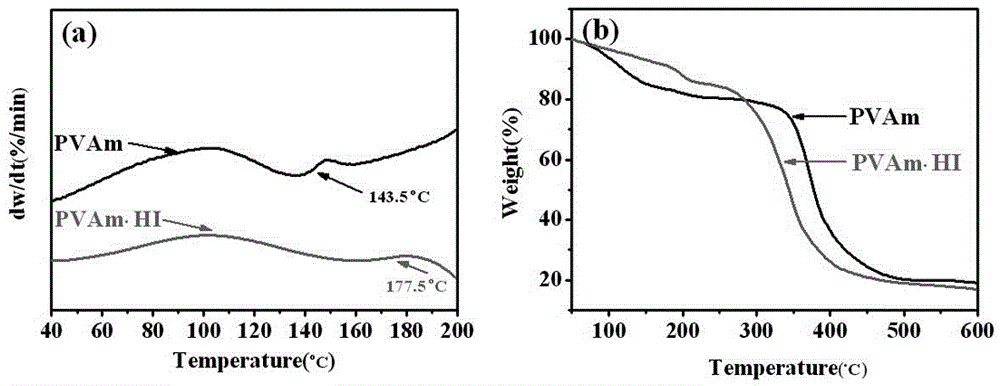

[0031] The preparation method of embodiment 1 PVAm HI

[0032] This embodiment provides a preparation method of PVAm HI, and its specific synthetic route is as follows:

[0033] .

[0034](1) Synthesis of PNVF: Add NVF aqueous solution and initiator AIBN into a three-necked flask, where ω(NVF)=20%, m(AIBA) / m(NVF)=0.5%. Nitrogen was passed to remove the oxygen in the system, and the mixture was stirred under reflux at 65° C. for 6 h. After the reaction was completed, the reaction solution was slowly added to four times the volume of acetone, stirred to precipitate a white precipitate, and filtered with suction to obtain a white precipitate. Dissolve the white precipitate in a small amount of deionized water, then slowly pour it into four times the volume of acetone for precipitation, and repeat the operation three times to ensure that there is no unreacted monomer NVF and initiator AIBN remaining in the precipitate. Vacuum dry at 40°C for 24h to constant weight, and calcul...

Embodiment 2

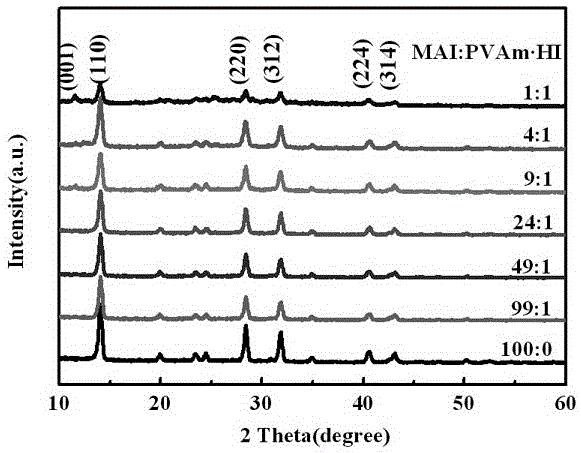

[0040] A kind of perovskite film, its general structural formula is: ABX 3 , the A is -[CH 2 CH(NH 3 + )] n - and CH 3 NH 3 + A mixture of the two, the B is Pb 2+ ; Said X is I - . In other embodiments, B can also be Sn 2+ or Cu 2+ etc.; X can also be Cl - or Br - Wait.

[0041] Its preparation method comprises the following steps:

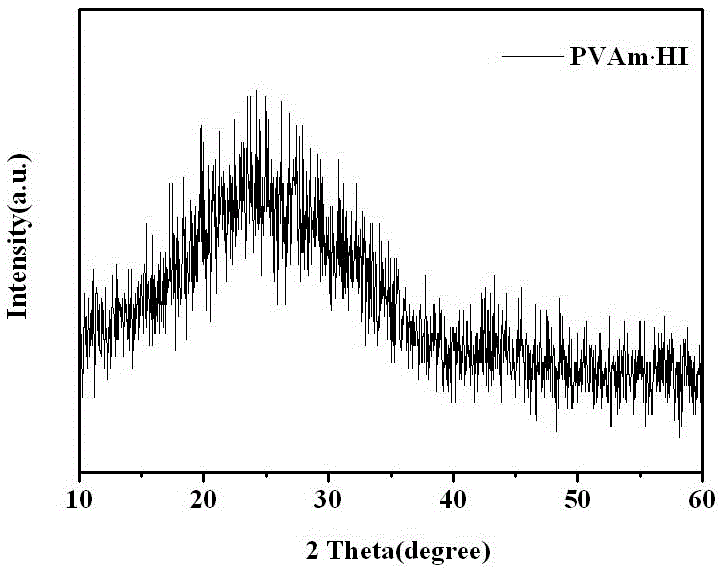

[0042] a) Acidification reaction of polyvinylamine PVAm with hydroiodic acid HI to obtain polyvinylaminoiodate PVAm·HI;

[0043] b) PVAm HI, methylamine iodide MAI and lead iodide PbI 2 Add it into an organic solvent and stir at 60°C for 12h to obtain a perovskite precursor solution; in step b), the amino groups in the MAI and PVAm·HI and PbI 2 The molar ratio of C(PbI 2 )=1.25M, and the molar ratio of MAI and PVAm HI is 24:1, the organic solvent is a mixture of dimethyl sulfoxide and γ-butyrolactone; dimethyl sulfoxide and γ-butyrolactone by volume 3:7 for mixing.

[0044] c) Spin-coating: Spin-coat at 1000r.p.m for 20s, then s...

Embodiment 3

[0046] A kind of perovskite thin film, with embodiment 2.

[0047] Its preparation method comprises the following steps:

[0048] a) Acidification reaction of polyvinylamine PVAm with hydroiodic acid HI to obtain polyvinylaminoiodate PVAm·HI;

[0049] b) PVAm HI, methylamine iodide MAI and lead iodide PbI 2 Add it into an organic solvent and stir at 50°C for 14h to obtain a perovskite precursor solution; in step b), the amino groups in the MAI and PVAm·HI and PbI 2 The molar ratio of C(PbI 2 )=1.25M, and the molar ratio of MAI and PVAm HI is 24:1, the organic solvent is a mixture of dimethyl sulfoxide and γ-butyrolactone; dimethyl sulfoxide and γ-butyrolactone by volume 2:7 for mixing.

[0050] c) Spin-coating: first spin-coat at 1200r.p.m for 15s, then spin-coat at 3500r.p.m for 25s; after spin-coating, add toluene and continue spin-coating to remove the solvent to obtain a perovskite film. Lower annealing for 12 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com