Distributive stress measurement-based pipeline interior corrosion monitoring method

A distributed strain and internal corrosion technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, analysis of materials, etc., can solve problems such as low detection efficiency, flammability and explosion, and inability to assess the safety status of pipeline corrosion defects , to achieve the effect of high measurement accuracy and non-destructive structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

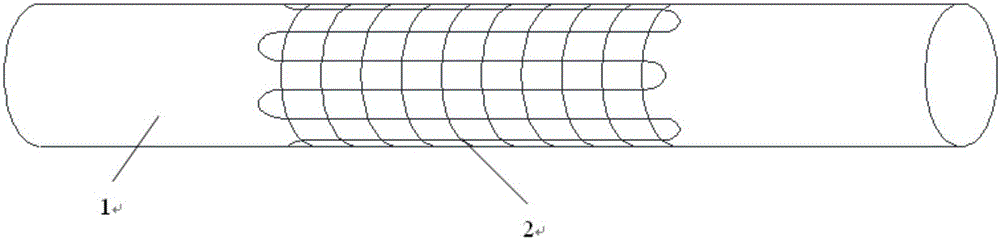

[0017] Step 1: In order to ensure that the polyimide optical fiber 2 is fully in contact with the outer surface of the metal pipe 1 and avoid measurement errors caused by strain transfer, first use a grinder to polish the outer surface of the metal pipe 1 to remove the paint layer, and then dip it with absorbent cotton balls Scrub the sanded area with absolute alcohol.

[0018] Step 2: Use epoxy resin glue to paste the polyimide optical fiber on the outer wall of the metal pipe at equal intervals along the ring direction of the metal pipe. The angle between the optical fiber and the metal pipe ring direction is controlled within 10°; After the polyimide fiber, the polyimide fiber is reciprocated and parallelly pasted on the surface of the metal pipe at equal intervals. The polyimide fiber is parallel to the metal pipe axis, and the polyimide fiber is pasted along the ring and axial The imide optical fiber forms an optical fiber monitoring network on the surface of the metal pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com