Full aluminum type plate heat exchanger for cooling heating part on electric vehicle

A technology for plate heat exchangers and electric vehicles, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as increasing the cost of heat exchangers, affecting heat exchange performance, and wasting space in the car , to minimize volume and weight, improve heat transfer efficiency, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

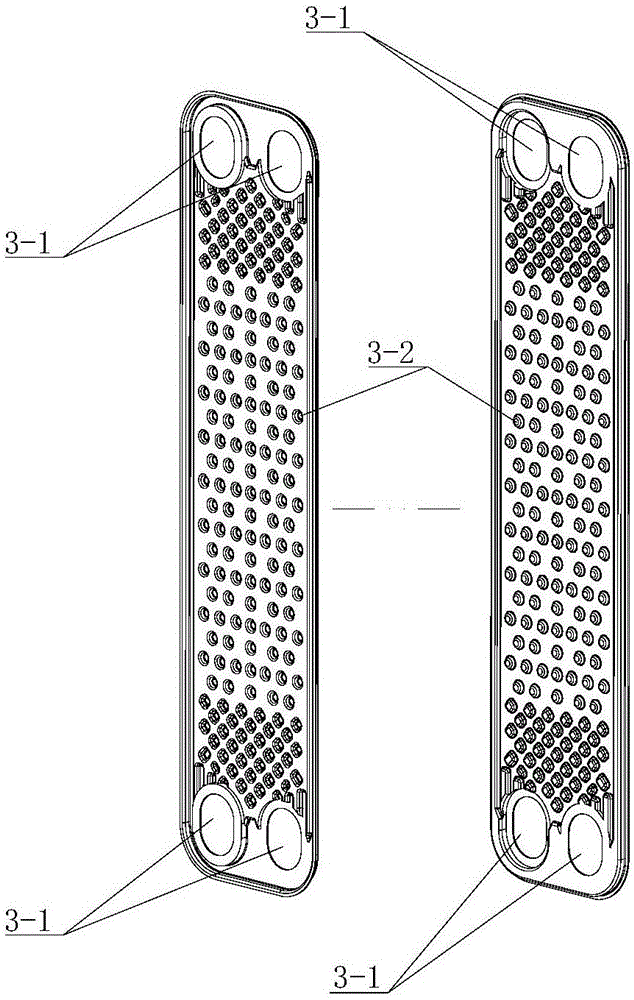

[0036] see Figure 1-8, an all-aluminum plate heat exchanger for cooling heating parts on electric vehicles, mainly including a front end plate 1, a rear end plate 2 arranged parallel to the front end plate, and several heat exchange plates 3 arranged between the front and rear end plates , Between the front end plate and the heat exchange plate located at the front end, between the adjacent heat exchange plates and between the rear end plate and the heat exchange plate located at the rear end all form a sandwich cavity. The above-mentioned front end plate, rear end plate, and several heat exchange plates are all made of aluminum alloy materials, and are integrally connected by brazing. That is, the edge of the front end plate and the edge o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com