A method for improving oxidation resistance of carbon anode for electrolytic aluminum

An anti-oxidation, carbon anode technology, applied in the field of industrial catalysis and organic chemicals, can solve the problems of difficult coating, little blocking effect, poor adhesion, etc., achieve simple and easy-to-understand preparation methods, and improve high-temperature coking value. , the effect of improving the coking properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

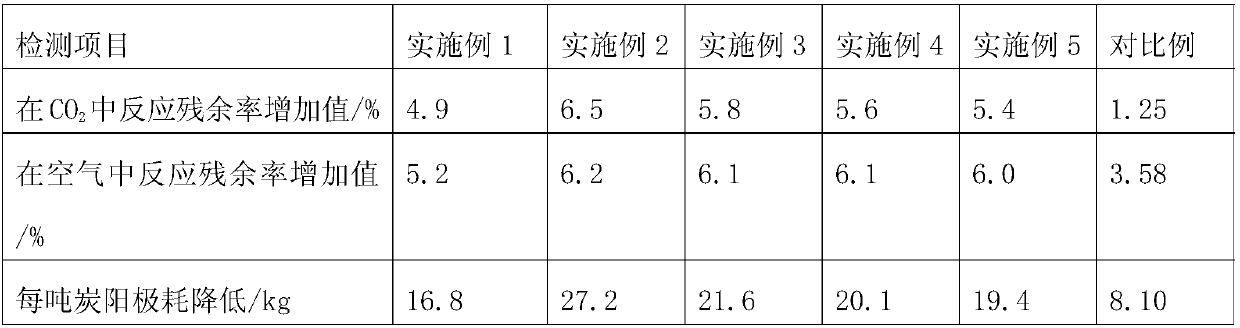

Examples

Embodiment 1

[0028] A method for improving the oxidation resistance of a carbon anode for electrolytic aluminum, comprising the following steps:

[0029] (1) Preparation of modified coal tar pitch: mix coal tar pitch and pitch modifier A, heat up to 180°C for cross-linking and fusion for 1 min, then lower the temperature after cross-linking and fusion to 90°C, and then add asphalt modification Agent B and stirred for 20 minutes, after cooling, the modified coal tar pitch can be obtained and set aside;

[0030] According to parts by weight, 50 parts of coal tar pitch, 5 parts of asphalt modifier A, and 3 parts of asphalt modifier B;

[0031] Wherein, the asphalt modifier A includes 1 part of modified diatomite and 2 parts of modified bentonite in parts by weight;

[0032] Among them, the modified diatomite is calcined at 500°C for 10 minutes, and after cooling, it is crushed by ultrasonic wave until the particle size is 100 mesh;

[0033] Among them, the modified bentonite is mechanically...

Embodiment 2

[0041] A method for improving the oxidation resistance of a carbon anode for electrolytic aluminum, comprising the following steps:

[0042] (1) Preparation of modified coal tar pitch: mix coal tar pitch and pitch modifier A, heat up to 200°C for cross-linking and fusion for 30 minutes, then lower the temperature after cross-linking and fusion to 90°C, and then add asphalt modification Add agent B and stir for 30 minutes, and after cooling, the modified coal tar pitch can be obtained and set aside;

[0043] 85 parts by weight of the coal tar pitch, 15 parts of asphalt modifier A, and 8 parts of asphalt modifier B;

[0044] Wherein, the asphalt modifier A includes 5 parts of modified diatomite and 8 parts of modified bentonite in parts by weight;

[0045] Among them, the modified diatomite is calcined at 600°C for 30 minutes, and after cooling, it can be pulverized by ultrasonic waves until the particle size is 150 mesh;

[0046] Among them, the modified bentonite is mechanic...

Embodiment 3

[0054] A method for improving the oxidation resistance of a carbon anode for electrolytic aluminum, comprising the following steps:

[0055] (1) Preparation of modified coal tar pitch: mix coal tar pitch and pitch modifier A, heat up to 185°C for cross-linking and fusion for 15 minutes, then lower the temperature after cross-linking and fusion to 100°C, and then add asphalt modification Agent B and stirred for 23 minutes, after cooling, the modified coal tar pitch can be obtained and set aside;

[0056] According to parts by weight, 55 parts of coal tar pitch, 8 parts of asphalt modifier A, 4 parts of asphalt modifier B;

[0057] Wherein, the asphalt modifier A includes 2 parts of modified diatomite and 3 parts of modified bentonite in parts by weight;

[0058] Among them, the modified diatomite is calcined at 540°C for 18 minutes, and after cooling, it can be pulverized by ultrasonic waves until the particle size is 120 mesh;

[0059] Among them, the modified bentonite is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com