Novel biodegradable Mg-Zn-Y-Nd-Ag antimicrobial magnesium alloy and preparation method thereof

A biodegradable, magnesium alloy technology, applied in the field of new biodegradable Mg-Zn-Y-Nd-Ag antibacterial magnesium alloy and its preparation, can solve the problem of high infection rate of metal implant materials, achieve excellent antibacterial function, The effect of promoting bonding and uniform corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

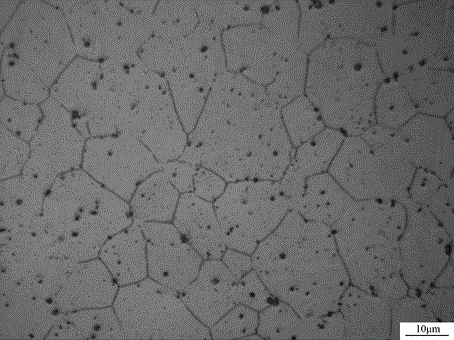

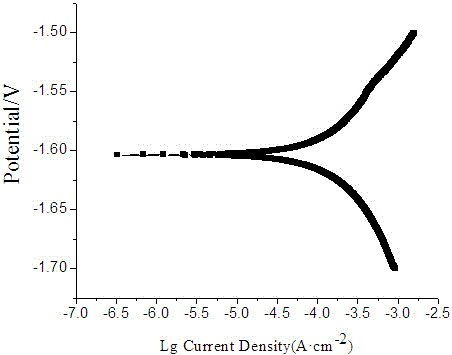

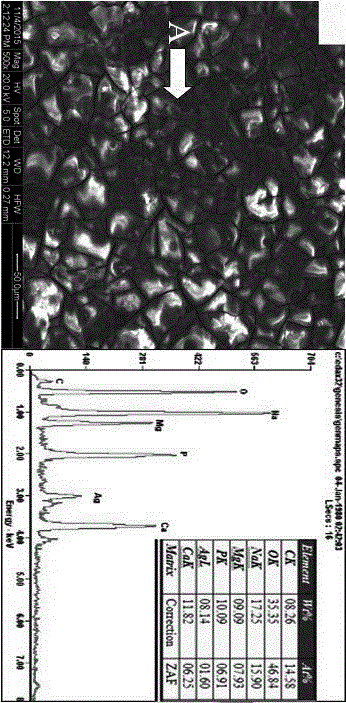

[0028] Preparation of Extruded Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.2 wt%Ag Magnesium Alloy

[0029] The preparation of the first step as-cast Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.2wt%Ag magnesium alloy comprises the following steps:

[0030] (1) Prepare raw materials:

[0031] Calculate the mass of each alloy element required for smelting, among which, the weight of Zn, Y, Nd in the charge is 1.2-1.3 times of its content in the magnesium alloy, and the weight of Ag is 1.1-1.2 times of its content in the magnesium alloy .

[0032] The charge quality required for this Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.2wt%Ag magnesium alloy of smelting 1kg is as follows:

[0033] High-purity magnesium ingot: 941.2g;

[0034] High-purity zinc ingot: 25g;

[0035] Mg-30wt%Y master alloy: 20.8g;

[0036] Mg-30wt%Nd master alloy: 20.8g;

[0037] High-purity silver wire: 2.2g;

[0038] The purity of high-purity magnesium ingot, high-purity zinc ingot and high-purity silver wire is ≥99.9%.

[0039] (2) Preparatio...

Embodiment 2

[0053] Preparation of Extruded Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.4wt%Ag Magnesium Alloy

[0054] The preparation of the first step as-cast Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.4wt%Ag magnesium alloy comprises the following steps:

[0055] (1) Prepare raw materials:

[0056] Calculate the mass of each alloy element required for smelting, wherein the amount of Zn, Y, Nd in the furnace charge is 1.2-1.3 times of its content in the magnesium alloy, and the amount of Ag is 1.1-1.2 times of its content in the magnesium alloy.

[0057] The charge quality required for this Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.4wt%Ag magnesium alloy of smelting 1.1kg is as follows:

[0058] High-purity magnesium ingot: 1210g

[0059] High-purity zinc ingot: 32.2g

[0060] Mg-30wt%Y master alloy: 26.8g

[0061] Mg-30wt%Nd master alloy: 26.8g

[0062] High-purity silver wire: 5.7g

[0063] The purity of high-purity magnesium ingot, high-purity zinc ingot and high-purity silver wire is ≥99.9%.

[0064] (2) Preparation ...

Embodiment 3

[0078] Preparation of Extruded Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.6wt%Ag Magnesium Alloy

[0079] The preparation of the first step cast state Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.6wt%Ag magnesium alloy comprises the following steps:

[0080] (1) Prepare raw materials:

[0081] Calculate the mass of each alloy element required for smelting, wherein the amount of Zn, Y, Nd in the furnace charge is 1.2-1.3 times of its content in the magnesium alloy, and the amount of Ag is 1.1-1.2 times of its content in the magnesium alloy .

[0082] The charge quality required for this Mg-2wt%Zn-0.5wt%Y-0.5wt%Nd-0.6wt%Ag magnesium alloy of smelting 1.3kg is as follows:

[0083] High-purity magnesium ingot: 1020g

[0084] High-purity zinc ingot: 27.2g

[0085] Mg-30wt%Y master alloy: 22.8g

[0086] Mg-30wt%Nd master alloy: 22.8g

[0087] High-purity silver wire: 7.3g

[0088] The purity of high-purity magnesium ingot, high-purity zinc ingot and high-purity silver wire is ≥99.9%.

[0089] (2) Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com