Preparation method of super-hydrophobic resin coating

A super-hydrophobic coating and hydrophobic technology, which is applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of fragile micro-nano structures on super-hydrophobic surfaces, loss of super-hydrophobic properties, and vulnerability to damage. Strong force, not easy to fall off, strong controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

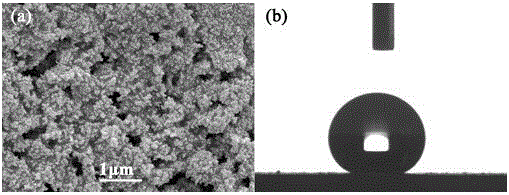

[0025] A preparation method of epoxy superhydrophobic coating: 1.8g epoxy resin E51, 0.18g epoxy resin curing agent 593, 0.55g hydrophobic nano-silicon dioxide and 15g acetone are stirred and mixed uniformly to obtain transparent coating, use The spray gun is sprayed on the glass sheet under the pressure of 2.5MPa, and cured at 100°C for 1 hour to obtain the epoxy resin superhydrophobic coating.

[0026] The SEM and contact angle photos of the resulting superhydrophobic coating can be found in figure 1 , the measured contact angle was 154.0±1°.

[0027] The relationship between the continuous residence time of strong acid or strong alkali droplets on the superhydrophobic coating and the contact angle is shown in figure 2 ,Depend on figure 2 It can be seen that the acid droplet (pH=1) is in continuous contact with the superhydrophobic coating, and after 20 minutes, the contact angle is 151±1°. After continuous contact with alkali drop (pH=14) for 25 minutes, the contact an...

Embodiment 2

[0029] A preparation method of epoxy resin superhydrophobic coating: 1.8g epoxy resin E51, 0.18g epoxy resin curing agent 593, 0.85g hydrophobic nano silicon dioxide and 15g n-hexane are stirred and mixed to obtain transparent coating, Use a spray gun to spray on a glass sheet under a pressure of 2.5MPa, and cure at 120°C for 1.5h to obtain an epoxy resin superhydrophobic coating.

[0030] The contact angle photo of the resulting superhydrophobic coating can be found in image 3 , the measured contact angle was 154±1°.

Embodiment 3

[0032] A preparation method of polyurethane superhydrophobic coating: 1.7g polyether polyurethane prepolymer, 0.17g 4,4'-methylenebis(2-chloroaniline), 0.6g hydrophobic nano-silica and 15g Xylene was stirred and mixed evenly to obtain a transparent coating, which was sprayed on a glass sheet with a spray gun at a pressure of 2.5 MPa, and cured at 100° C. for 1.5 h to obtain a polyurethane superhydrophobic coating. SEM and contact angle photos of gained polyurethane superhydrophobic coating are shown in Figure 4 , the measured contact angle was 152±1°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com