Optical fiber outer sheath material and preparation method thereof

A technology of optical fiber sheath and outer sheath, which is applied in the field of optical fiber outer sheath material and its preparation, can solve the problems of unfavorable optical fiber signal transmission, increased cost and single weight, inconvenient procurement and construction, etc., and achieves good chemical stability, Low friction coefficient, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

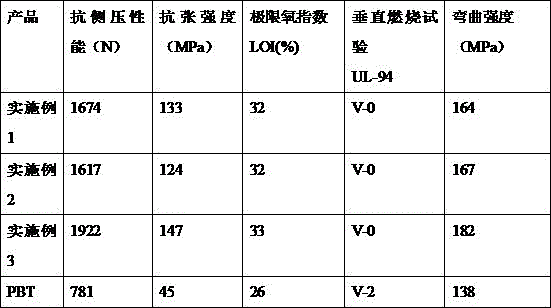

Examples

Embodiment 1

[0024] Composition of raw materials: 40 parts of polytrimethylene terephthalate, 5 parts of modified lignin, 25 parts of polybutylene terephthalate, 2 parts of anti-ultraviolet material (phenyl salicylate), compatibilizer (methanol methyl acrylate-glycidyl methacrylate-ethyl acrylate terpolymer) 2 parts, antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] Pentaerythritol ester) 1 part, coupling agent (maleic anhydride) 3 parts, nanoscale composite hydroxide-inorganic filler powder 2 parts, dispersant (sodium alginate) 0.1 part.

[0025] Modified lignin preparation method:

[0026] Take the lignin whose particle size is 80-200 mesh for subsequent use;

[0027] Take a coupling agent (γ-methacryloxypropyl-trimethoxysilane) with a mass ratio of 20:8:72, ammonia water and ethanol to prepare a mixed solution, stir and mix for 1 hour after the proportioning is completed, and set aside;

[0028] Soaking: add lignin into the mixed solution with a substance ra...

Embodiment 2

[0041] Composition of raw materials: 55 parts of polypropylene terephthalate, 10 parts of modified lignin, 35 parts of polybutylene terephthalate, 3 parts of anti-ultraviolet material (phenyl salicylate), compatibilizer (methanol methyl acrylate-glycidyl methacrylate-ethyl acrylate terpolymer) 3 parts, antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] Pentaerythritol ester) 2 parts, coupling agent (maleic anhydride grafted polypropylene) 5 parts, nanoscale composite hydroxide-inorganic filler powder 2 parts, dispersant (sodium hydroxymethyl cellulose) 0.2 parts.

[0042] The preparation method is the same as in Example 1.

Embodiment 3

[0044] The raw material weight composition of the optical fiber outer sheath material of the present invention: 50 parts of polytrimethylene terephthalate, 12 parts of modified lignin, 27 parts of polybutylene terephthalate, 2 parts of phenyl salicylate, cyclic Oxygen resin 2 parts of styrene-acrylonitrile-maleic anhydride terpolymer, 1 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, maleic anhydride 0.88 parts of grafted ethylene-propylene ternary rubber, 2 parts of maleic anhydride, 3 parts of nanoscale composite hydroxide-inorganic filler powder, and 0.12 parts of sodium hydroxymethyl cellulose.

[0045] The preparation method is as follows:

[0046] 1. Preparation of nanoscale composite hydroxide-inorganic filler powder:

[0047] After getting 0.25 kilogram of aluminum hydroxide and 0.125 kilogram of wollastonite into the ball mill jar, put 2 steel balls of 200 grams, 10 steel balls of 100 grams, 40 steel balls of 36 grams and 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com