Heat-resistant and flame-retardant composition and preparation method thereof

A flame retardant composition and heat-resistant technology, applied in the fields of new energy and environmental protection and energy saving, can solve the problem of low heat resistance, and achieve the effects of excellent flame retardant effect, excellent stability and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

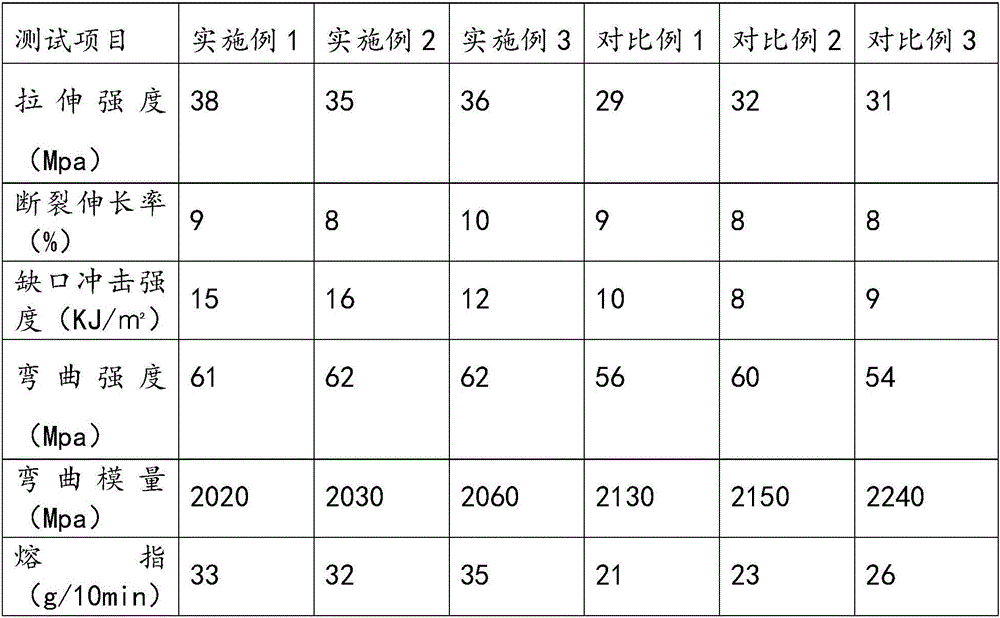

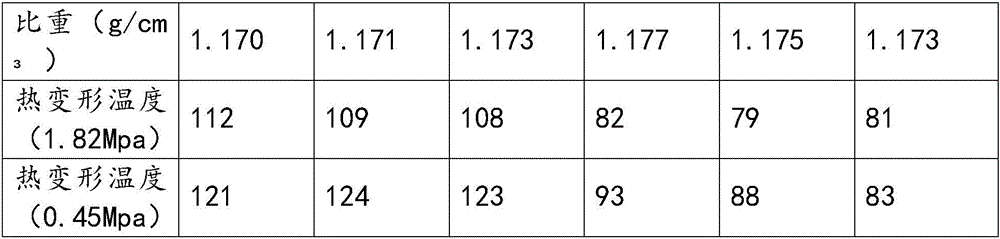

Examples

Embodiment 1

[0017] An efficient and environmentally friendly heat-resistant flame-retardant composition, 70 parts of the ABS resin, 15 parts of the flame retardant, 15 parts of the flame-retardant synergist, 15 parts of the heat-resistant modifier, the hard 0.1 part of zinc fatty acid, 1 part of said nitrile rubber, 0.5 part of said diphenylamine, 0.1 part of said o-hydroxybenzophenones; wherein said flame retardant synergist is made of aluminum hydroxide, mica powder and ultra-high molecular weight polysiloxane; wherein, the flame retardant synergist is a compound composed of aluminum hydroxide, mica powder and ultra-high molecular weight polysiloxane; preferably, the The ultra-high molecular weight polysiloxane is polydimethylsiloxane, the molecular weight of the polydimethylsiloxane is ≥30,000, and its viscosity is ≥500mPa·s at a temperature of 25°C. The heat-resistant modifier is N-isopropylmaleimide, N-cyclohexylmaleimide, poly(N-n-octadecylmaleimide), N-phenylmaleimide One or more ...

Embodiment 2

[0019] A high-efficiency and environmentally friendly heat-resistant flame-retardant composition, 80 parts of the ABS resin, 20 parts of the flame retardant, 20 parts of the flame-retardant synergist, 25 parts of the heat-resistant modifier, and 20 parts of the stearin 1.5 parts of zinc acid, 5 parts of said nitrile rubber, 1.0 part of said p-phenylenediamine, 0.8 part of said o-hydroxybenzophenones; wherein said flame retardant synergist is made of aluminum hydroxide, mica Powder and ultra-high molecular weight polysiloxane compound. Other component proportioning is identical with the technical scheme among the embodiment 1.

Embodiment 3

[0021] A high-efficiency and environmentally friendly heat-resistant flame-retardant composition, 90 parts of ABS resin, 25 parts of flame retardant, 30 parts of flame-retardant synergist, 0 parts of heat-resistant modifier, 2 parts of zinc stearate, 10 parts of nitrile rubber 1.5 parts, 1.5 parts of diphenylamine, 1 part of o-hydroxybenzophenones; wherein, the flame retardant synergist is a compound composed of aluminum hydroxide, mica powder and ultra-high molecular weight polysiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com