Thermoplastic elastomer composite composition suitable for in-mould blowing

A composite material and plasticity technology, which is applied in the field of in-mold foaming materials, can solve problems such as labor-intensive and inability to achieve lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

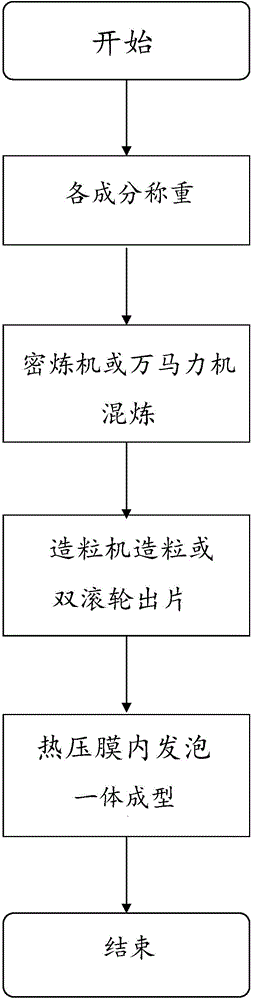

Method used

Image

Examples

Embodiment 1

[0024] 90 parts by weight of styrene elastomer, 5 parts by weight of styrene-ethylene / butylene-styrene and its oil-extended composite material (styrene-ethylene / butylene-styrene and white wax oil are first soaked or granulated obtain), 2.5 parts by weight of 4,4 oxobisphenylsulfonyl hydrazide and 3.5 parts by weight of microcapsule blowing agent, 0.8 parts by weight of dicumyl peroxide and 0.2 parts by weight of cyanuric acid three The allyl ester is mixed into the internal mixer, and fused at a high temperature of 100°C. After mixing evenly, it is put into the single-screw granulator to form particles. Then, after weighing the above particles, put them into The mold in the molding machine is heated and foamed at 150°C, and the foaming in the mold is completed after cooling, and the density of the foamed product is 0.28g / cm 3 .

Embodiment 2

[0026] 65 parts by weight of polypropylene elastomer, 2 parts by weight of 4,4 oxobisbenzenesulfonyl hydrazide, 4 parts by weight of microcapsule blowing agent, 5 parts by weight of styrene-butadiene-styrene and its Oil-extended composite material (obtained after soaking or granulating styrene-butadiene-styrene and white wax oil), 30 parts by weight of styrene-ethylene / butylene-styrene and its oil-extended composite material, 1.5 parts by weight Dicumyl peroxide and 1.2 parts by weight of triallyl cyanurate are mixed into a banburyer, and fused at a high temperature of 120°C. After mixing evenly, they are then put into a double-roller tablet machine to produce tablets. , and then, after weighing the above-mentioned sheet, put it into the mold in the molding machine whose temperature has been set, heat and foam at 170°C, and complete the foaming in the mold after cooling. The density of the foamed product is 0.24g / cm 3 .

Embodiment 3

[0028] 50 parts by weight of thermoplastic polyurethane elastomer, 2 parts by weight of 4,4 oxobisphenylsulfonyl hydrazide, 3 parts by weight of microcapsule foaming agent, 40 parts by weight of styrene-butadiene-styrene and Its oil-extended composite material (obtained after soaking or granulating styrene-butadiene-styrene and white wax oil first), 0.5 parts by weight of 1,4-bis-tert-butylperoxycumene, 0.1 parts by weight of Triallyl isocyanurate, 5 parts by weight of calcium carbonate and 5 parts by weight of maleic anhydride and polyethylene graft copolymer or (maleic anhydride and EVA graft copolymer) are mixed and put into a banbury mixer, Carry out high-temperature fusion at 150°C, knead evenly, and then put it into the double-roller tablet machine to output the sheet. Then, after weighing the above-mentioned sheet, put it into the mold in the molding machine with the temperature set, and pass through 170 Heating at ℃, foaming, and foaming in the mold is completed after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com