Tribranched azobenzene hybrid material with photoinduced deformation, and preparation method thereof

A hybrid material and photodeformation technology, applied in the field of composite functional materials, can solve the problem of single form of new energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

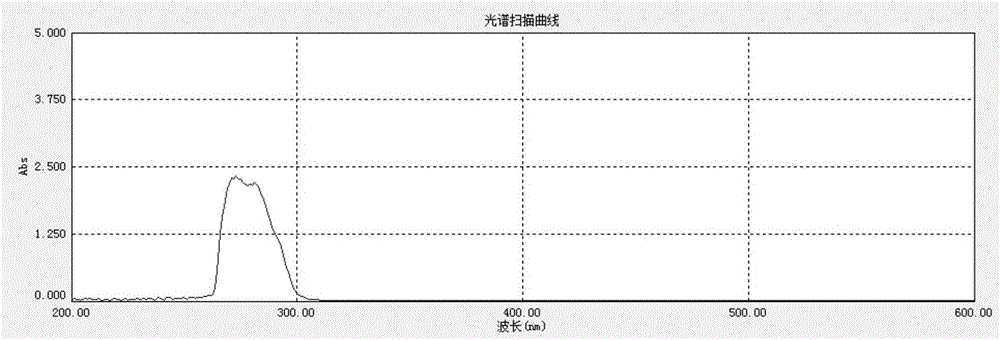

Image

Examples

Embodiment 1

[0026] 1) Preparation of three-branched azobenzene: 30 mmol of p-aminoazophenyl-4-sulfonic acid, 70 mmol of triphenyl phosphite and 50 mmol of pyridine were dissolved in dimethylacetamide to obtain a yellow transparent solution. Under the protection of nitrogen, react with 10 mmol 1,3.5-benzenetricarboxylic acid, raise the temperature to 115° C., and react for 4 hours to obtain the crude product of triple azo. After recrystallization, the three-branched azobenzene monomer we want is obtained.

[0027] 2) Preparation of photodeformable three-branched azobenzene hybrid material: three-branched azobenzene was added to polydiallyldimethylammonium chloride, and their concentration ratio was 1 mmol: 100 mmol. Wherein the concentration ratio of sulfonate ion to polydiallyldimethylammonium chloride ion is 3mmol:100mmol. A reddish-brown three-branched azobenzene hybrid material was obtained.

[0028] The hybrid material is made into a thin film by spin coating, and the thin film will...

Embodiment 2

[0030] 1) Preparation of three-branched azobenzene: 40 mmol of p-aminoazophenyl-4-sulfonic acid, 70 mmol of triphenyl phosphite and 50 mmol of pyridine were dissolved in dimethylacetamide to obtain a yellow transparent solution. Under the protection of nitrogen, react with 10 mmol 1,3.5-benzenetricarboxylic acid, raise the temperature to 115° C., and react for 4 hours to obtain the crude product of triple azo. After recrystallization, the three-branched azobenzene monomer we want is obtained.

[0031] 2) Preparation of photodeformable three-branched azobenzene hybrid material: three-branched azobenzene was added to polydiallyldimethylammonium chloride, and their concentration ratio was 1.5mmol:100mmol. Wherein the concentration ratio of sulfonate ion and polydiallyldimethylammonium chloride ion is 4.5mmol:100mmol. A reddish-brown three-branched azobenzene hybrid material was obtained.

[0032] The hybrid material is made into a thin film by spin coating, and the thin film wi...

Embodiment 3

[0034] 1) Preparation of three-branched azobenzene: 50 mmol of p-aminoazophenyl-4-sulfonic acid, 70 mmol of triphenyl phosphite and 50 mmol of pyridine were dissolved in dimethylacetamide to obtain a yellow transparent solution. Under the protection of nitrogen, react with 10 mmol 1,3.5-benzenetricarboxylic acid, raise the temperature to 115° C., and react for 4 hours to obtain the crude product of triple azo. After recrystallization, the three-branched azobenzene monomer we want is obtained.

[0035] 2) Preparation of photodeformable three-branched azobenzene hybrid material: three-branched azobenzene was added to polydiallyldimethylammonium chloride, and their concentration ratio was 2mmol:100mmol. Wherein the concentration ratio of sulfonate ion to polydiallyldimethylammonium chloride ion is 6mmol:100mmol. A reddish-brown three-branched azobenzene hybrid material was obtained.

[0036] The hybrid material is made into a thin film by spin coating, and the thin film will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com