Preparation method of ring trapezoidal nitrophenyl silsesquioxane

A technology of silsesquioxane and nitrophenyl, applied in the direction of silicon organic compounds, etc., to achieve the effects of high yield, mild reaction conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

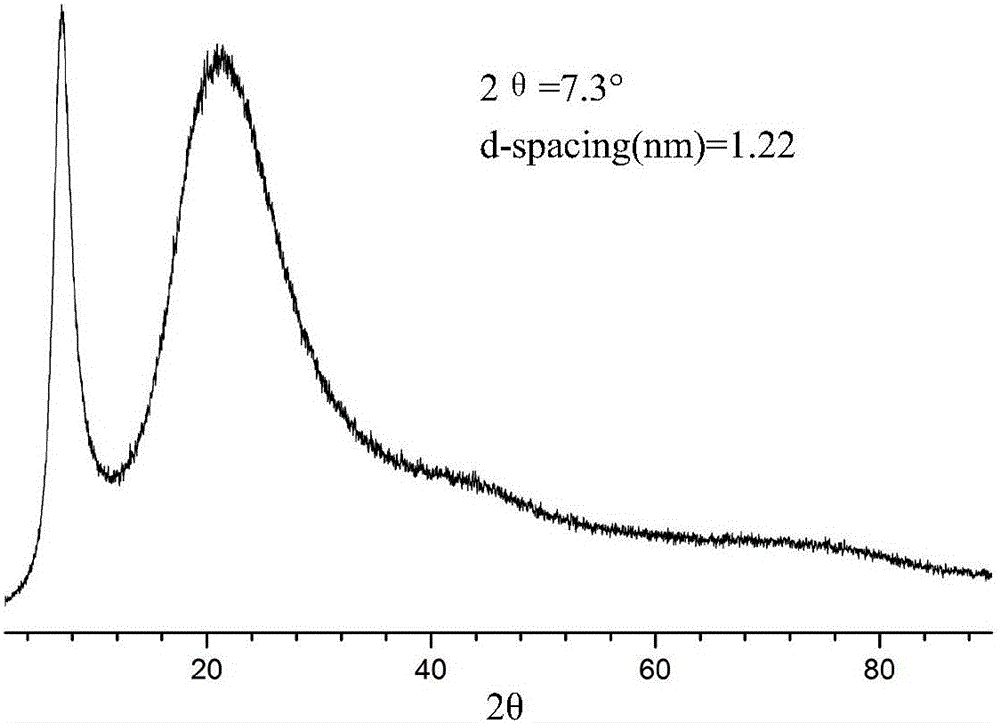

Image

Examples

Embodiment 1

[0026] 1) Add 4g of cyclic trapezoidal phenylsilsesquioxane (PPSQ) and 20mL of dichloromethane into a 250mL three-necked flask with reflux condenser, constant pressure dropping funnel, temperature control device, nitrogen protection and magnetic stirring, and stir , the temperature of the ice-water bath was controlled at 0°C, and 20mL of 80% nitric acid, 40mL of acetic anhydride, and 10mL of acetic acid were slowly added dropwise in sequence for about 1 hour. After the addition, the temperature was raised to 30°C and reacted for 6 hours to obtain a reaction solution.

[0027] 2) The reaction solution obtained in step 1) is poured into 50 mL of ice water, the mixed solution is rotary evaporated to remove dichloromethane, and a yellow solid is precipitated, which is filtered by suction to obtain a filter cake, which is successively washed with saturated Na 2 CO 3 Wash the filter cake with solution until there are no air bubbles, wash with distilled water until the filtrate is ne...

Embodiment 2

[0032] 1) Add 8g of cyclic trapezoidal phenylsilsesquioxane (PPSQ) and 40mL of dichloromethane into a 500mL three-necked flask with reflux condenser, constant pressure dropping funnel, temperature control device, nitrogen protection and magnetic stirring, and stir , the temperature of the ice-water bath was controlled at 0°C, and 40mL of 80% nitric acid, 80mL of acetic anhydride, and 20mL of acetic acid were slowly added dropwise in sequence for about 1 hour. After the addition, the temperature was raised to 30°C and reacted for 7 hours to obtain a reaction solution.

[0033] 2) The reaction solution obtained in step 1) is poured into 100 mL of ice water, the mixed solution is rotary evaporated to remove dichloromethane, and a yellow solid is precipitated, which is filtered by suction to obtain a filter cake, which is successively washed with saturated Na 2 CO 3 Wash the filter cake with solution until there are no air bubbles, wash with distilled water until the filtrate is n...

Embodiment 3

[0035]1) Add 8g of cyclic trapezoidal phenylsilsesquioxane (PPSQ) and 60mL of dichloromethane into a 500mL three-necked flask with reflux condenser, constant pressure dropping funnel, temperature control device, nitrogen protection and magnetic stirring, and stir , the temperature of the ice-water bath was controlled at 0°C, and 40mL of 75% nitric acid, 80mL of acetic anhydride, and 20mL of acetic acid were slowly added dropwise in sequence for about 1 hour. After the addition, the temperature was raised to 35°C and reacted for 6 hours to obtain a reaction solution.

[0036] 2) The reaction solution obtained in step 1) is poured into 100 mL of ice water, the mixed solution is rotary evaporated to remove dichloromethane, and a yellow solid is precipitated, which is filtered by suction to obtain a filter cake, which is successively washed with saturated Na 2 CO 3 Wash the filter cake with solution until there are no air bubbles, wash with distilled water until the filtrate is ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com