Graphene oxide/polymer composite antibacterial material and preparation method thereof

A composite antibacterial and polymer technology, applied in the field of medical antibacterial materials, can solve the problems of film peeling and poor adhesion of the film base, and achieve the effects of easy operation, improved biocompatibility, and high biosafety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Cut the silicon rubber sheet into 2×2cm size, ultrasonically clean it in acetone, ethanol and deionized water for 5 minutes respectively, and dry it; place the silicon rubber after ultrasonic cleaning vertically in the UV box, close the door of the UV box, and turn on the UV box. lamp, carry out ultraviolet treatment for 20min, and the ultraviolet wavelength range is 180nm; activate the surface of the silicone rubber; then soak the treated medical silicone rubber in 2% ethanol solution of 3-aminopropyltriethoxysilane for 15 minutes After taking it out, rinse it with absolute ethanol and dry it in the air; immerse the silicone rubber after the grafted coupling agent in a graphene oxide suspension with a concentration of 50 μg / ml and soak for 15 minutes to obtain a graphene oxide / silicone rubber composite antibacterial material.

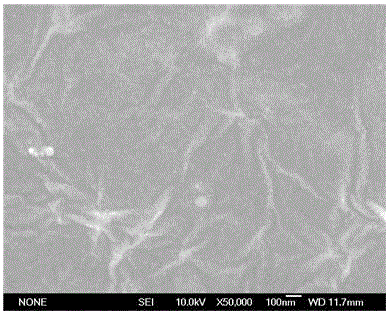

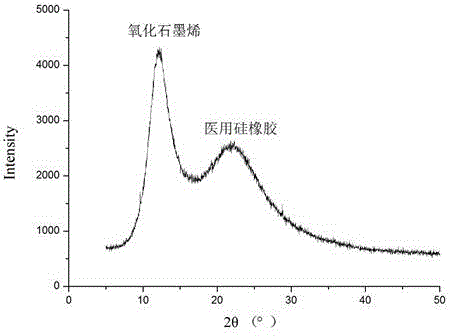

[0040] figure 1 It is the surface topography figure of the graphene oxide / silicone rubber composite antibacterial material obtained in this expe...

Embodiment 2

[0046] Cut the silicone rubber sheet into 2×2cm size, ultrasonically clean it in acetone, ethanol and deionized water for 5 minutes respectively, and dry it; place the silicon rubber after ultrasonic cleaning in an argon plasma atmosphere for 30 minutes to make the surface of the silicone rubber Activation; then soak the treated silicone rubber in 1% ethanol solution of 3-aminopropyltriethoxysilane for 5 minutes, take it out, rinse it with water and absolute ethanol and dry it in turn; the grafted coupling agent The final silicone rubber was immersed in a graphene oxide suspension with a concentration of 30 μg / ml for 20 min to obtain a graphene oxide / silicone rubber composite antibacterial material.

[0047] The antibacterial performance test of the composite antibacterial material obtained in the present invention: select Escherichia coli and Staphylococcus aureus as examples; the method is the same as in Example 1, and the finally obtained bacteriostatic rates are 92.6% and 8...

Embodiment 3

[0049] Cut the silicone rubber sheet into a size of 2×2 cm, ultrasonically clean it in acetone, ethanol and deionized water for 5 minutes, and dry it; place the silicon rubber after ultrasonic cleaning vertically in the UV box, close the door of the UV box, and turn on the UV box. lamp, carry out ultraviolet treatment for 20min, and the ultraviolet wavelength range is 200nm; activate the surface of the silicone rubber; then soak the treated medical silicone rubber in 19% ethanol solution of γ-mercaptopropyltrimethoxysilane for 10 min After taking it out, rinse it with water and absolute ethanol in turn and dry it; immerse the silicone rubber after the grafted coupling agent in a suspension of 10 µg / ml graphene oxide for 30 minutes to obtain a graphene oxide / silicone rubber composite antibacterial material .

[0050] The composite antibacterial material obtained in the present invention is tested for antibacterial performance: select Escherichia coli and Staphylococcus aureus a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com