Full recovery fuel combustion steam power cycle thermal power generation system and its technology

A steam power and thermal power generation technology, applied in the field of boilers, can solve the problems of poor thermodynamics, increased investment in boiler equipment, and difficult low-temperature corrosion, and achieve the effects of avoiding temperature difference pinch limit, saving fuel consumption, and avoiding low-temperature corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

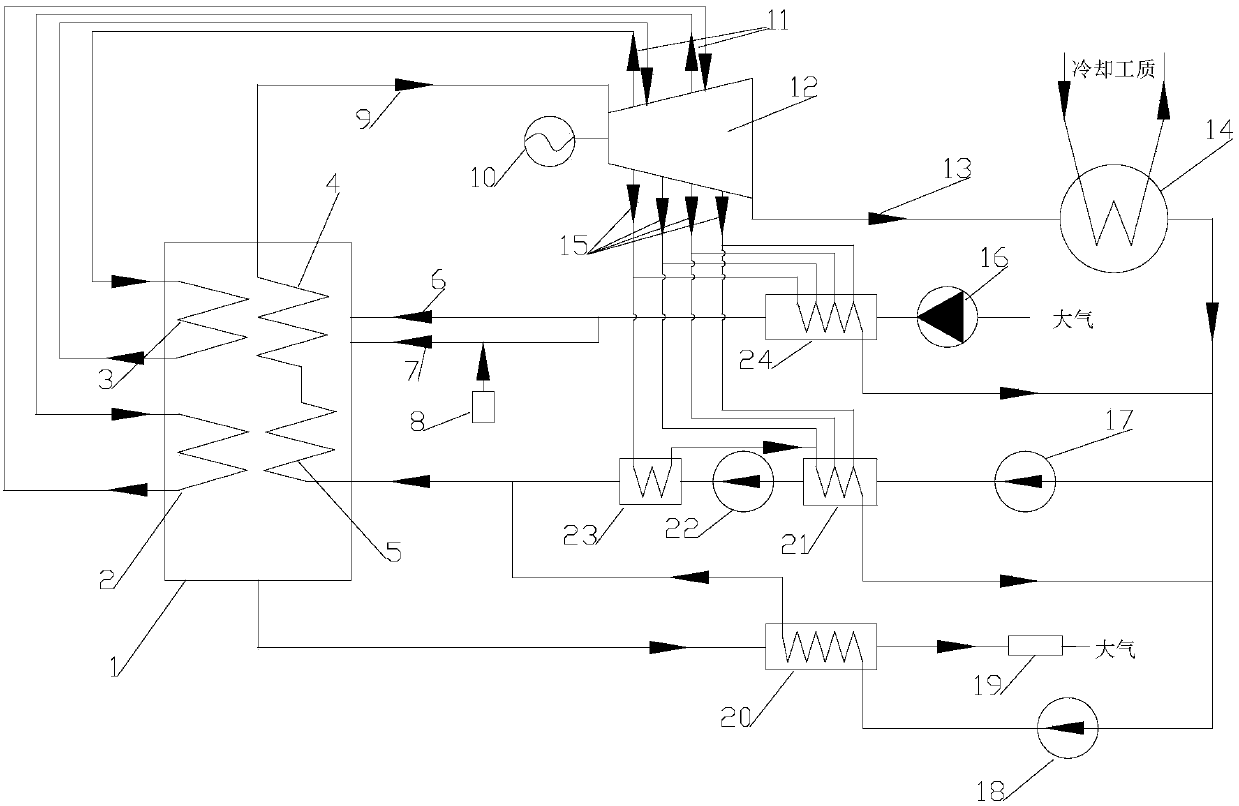

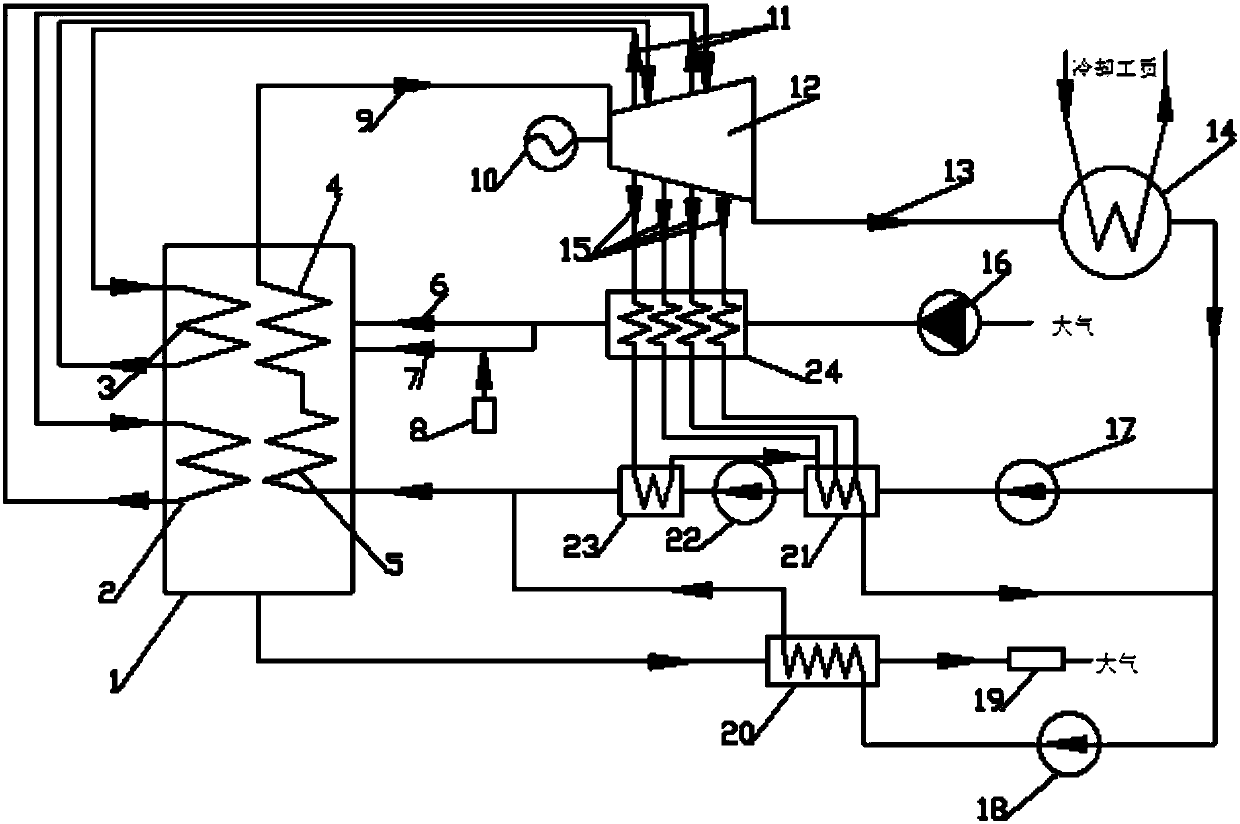

[0024] see figure 1 As shown, a fuel combustion steam power cycle thermal power generation system of the present invention includes a furnace and a boiler high-temperature flue gas section 1, a first reheater 2, a second reheater 3, a superheater 4, and a water-cooled wall 5. Main steam pipeline 9, generator 10, steam turbine 12, condenser 14, fan 16, condensate pump 17, high-pressure condensate pump 18, flue gas purification system 19, high-pressure condensate heater 20, low-pressure heater 21, supply Water pump 22, high pressure heater 23 and air heater 24.

[0025] The boiler high-temperature flue gas section of the furnace 1 is equipped with a first reheater 2, a second reheater 3, a superheater 4, and a water-cooled wall 5; Theoretically speaking, the flue gas above the average endothermic temperature belongs to the high temperature flue gas. The first reheater 2 and the second reheater 3 are connected to the reheat steam inlet and outlet 11 of the steam turbine through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com