Liquid hydrogen vaporization control method for hydrogen energy unmanned aerial vehicles

A control method and technology of unmanned aerial vehicle, applied in the direction of engine control, mechanical equipment, combustion engine, etc., can solve the problems of no major advantages, storage container consumption, high thermal insulation design requirements, and achieve the goal of reducing self-weight and improving utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

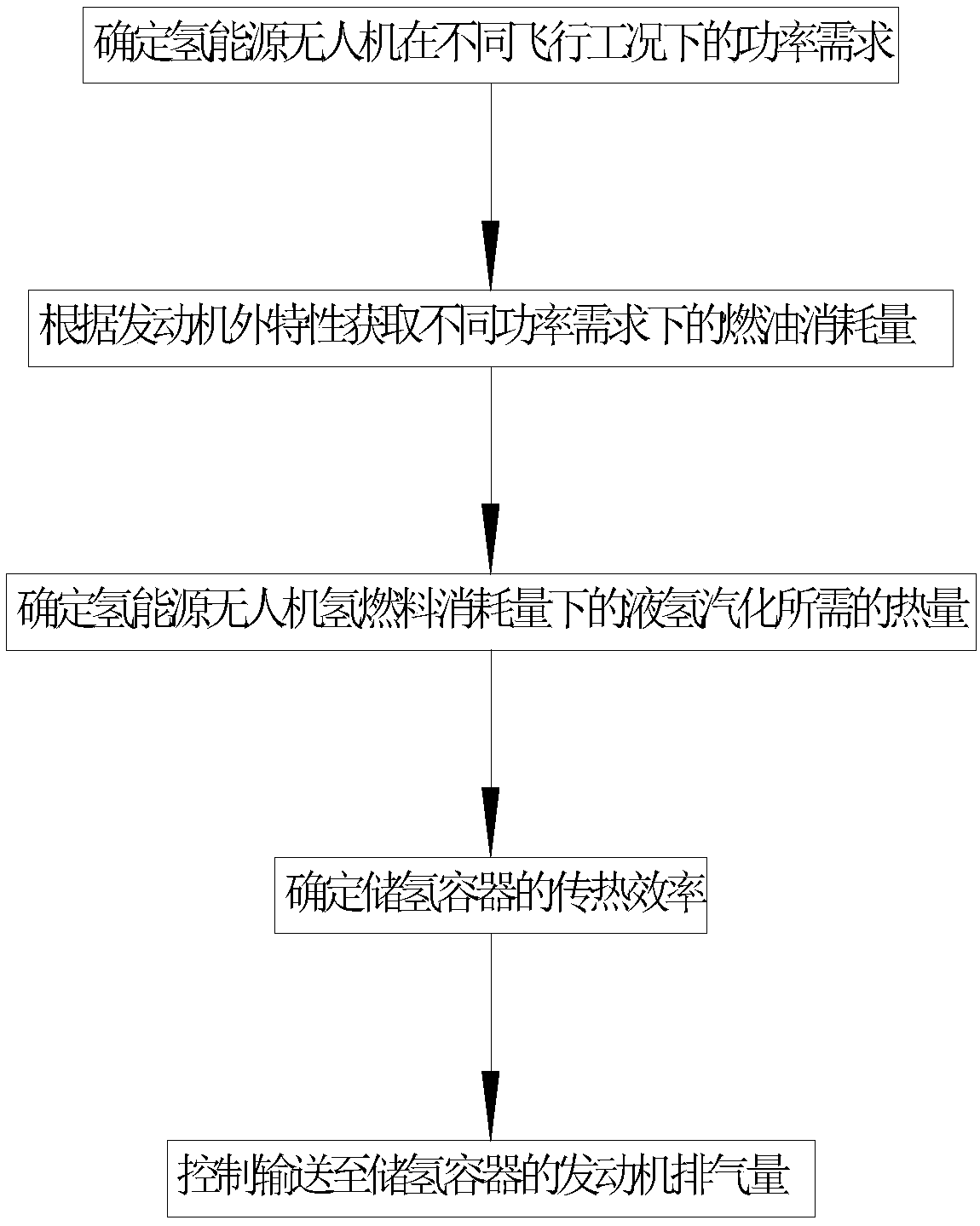

[0033] For ease of understanding, the attached figure 1 The specific implementation steps of the present invention are described as follows:

[0034] A method for fuel management of a hydrogen energy unmanned aerial vehicle based on liquid hydrogen vaporization control, comprising the following steps:

[0035] Step 1: Determine the power requirements of the hydrogen energy UAV under various flight conditions;

[0036] Step 2: Obtain the hydrogen fuel consumption under different power requirements according to the external characteristic curve of the engine;

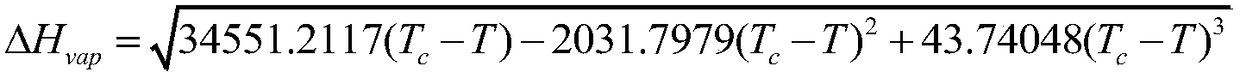

[0037] Step 3: Determine the heat required for the vaporization of liquid hydrogen under the hydrogen fuel consumption of the hydrogen energy UAV;

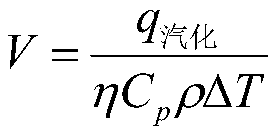

[0038] Step 4: Determine the heat transfer efficiency of the hydrogen storage container;

[0039] Step 5: Control the exhaust volume of the engine delivered to the hydrogen storage container to balance the vaporization amount of liquid hydrogen in the hydrogen storage cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com