Electrode without contact resistance

A non-contact, electrode technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of increasing the contact resistance value between electrodes, large gas production and power consumption, and increasing energy consumption, so as to eliminate contact resistance , reduce power consumption and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

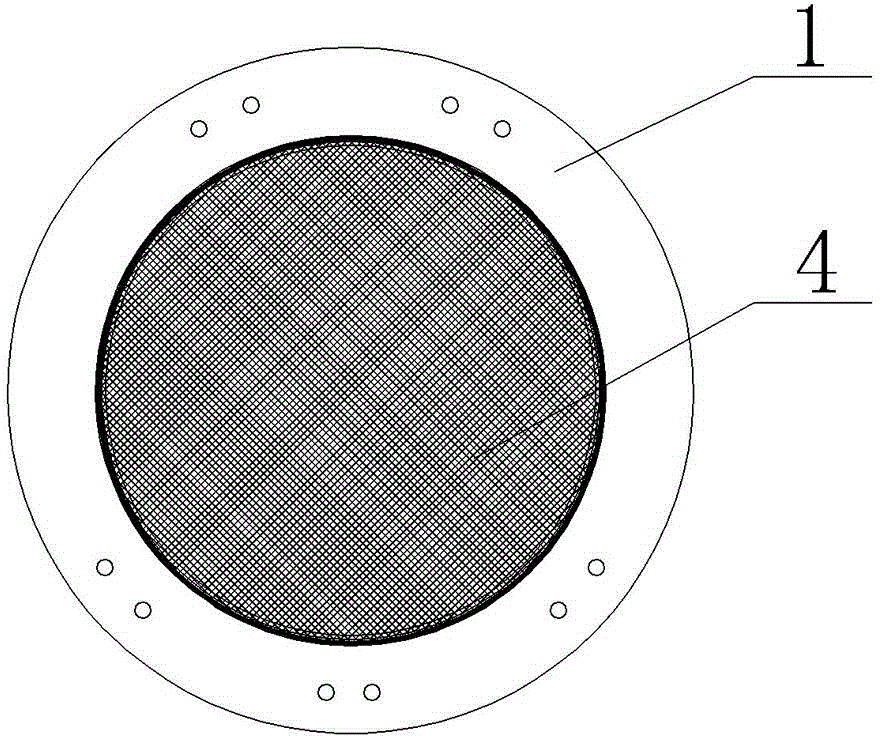

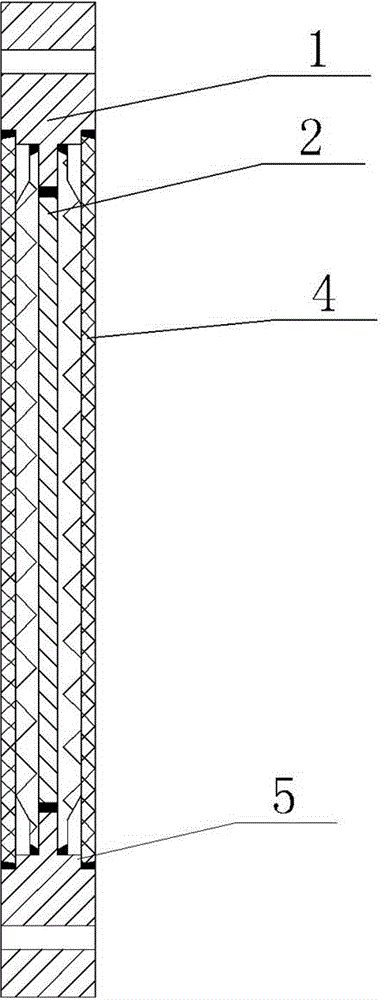

[0021] A kind of non-contact resistance electrode of present embodiment, non-contact resistance electrode comprises electrode plate assembly, steel wire mesh 3-1 and nickel-nickel alloy electrode mesh 4; Electrode plate assembly comprises carbon steel electrode frame 1 and is welded on The cold-rolled deep-drawn steel plate electrode plate 2 in the carbon steel electrode frame 1, the carbon steel electrode frame 1 is provided with an annular boss 5 on both sides, and the nickel-nickel alloy electrode mesh 4 is welded on the annular boss 5, and the steel metal The wire mesh 3-1 is welded between the nickel-nickel alloy electrode mesh 4 and the cold-rolled deep-drawn steel plate electrode plate 2.

[0022] The surface of the nickel-nickel alloy electrode mesh 4 in this embodiment is coated with a nickel-aluminum alloy active coating.

Embodiment 2

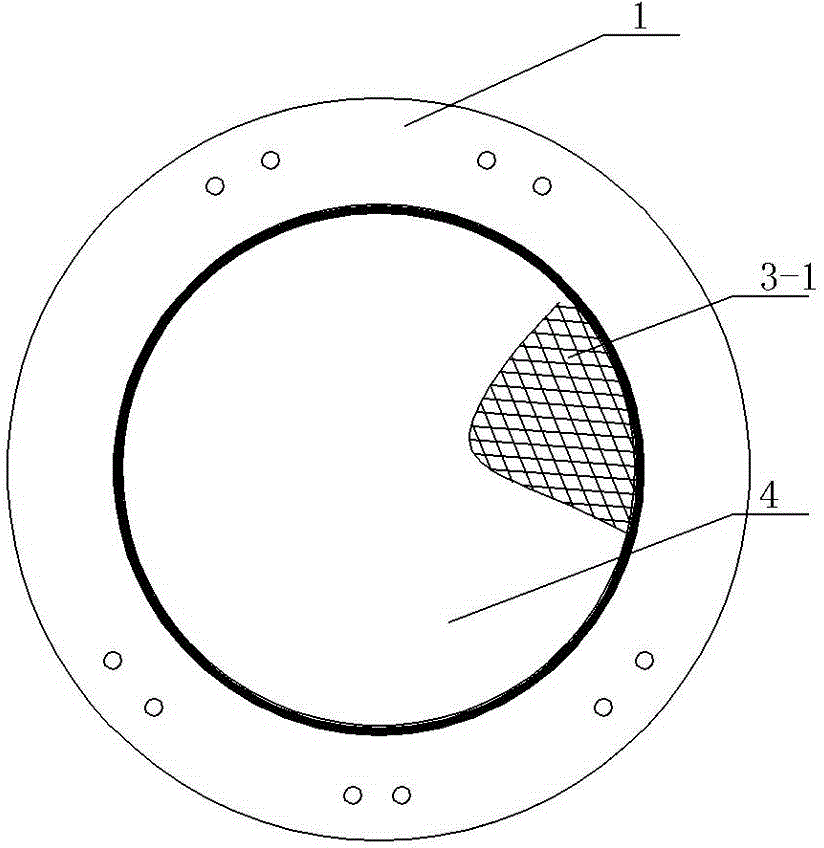

[0024] A kind of non-contact resistance electrode of present embodiment, non-contact resistance electrode comprises electrode plate assembly and nickel-nickel alloy electrode network 4; Rolled deep-drawn steel plate electrode plate 2, carbon steel electrode frame 1 is provided with annular bosses 5 on both sides, and nickel-nickel alloy electrode mesh 4 is welded on the annular boss 5, cold-rolled deep-drawn steel plate electrode plate 2 has several The protrusions 3-2 punched into an array are used as support bodies.

[0025] The surface of the nickel-nickel alloy electrode mesh 4 in this embodiment is coated with a nickel-aluminum alloy active coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com