A method for coating Teflon on the surface of a slider

A surface coating and Teflon technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of large pollution and low efficiency of the anti-corrosion treatment process on the surface of the slider, and achieve high efficiency , fast speed, improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

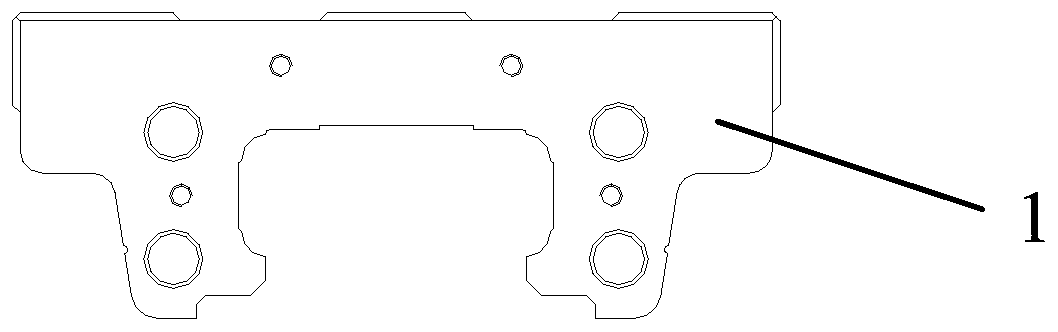

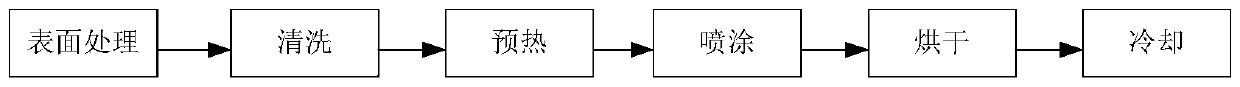

[0027] Such as Figure 1-3 Shown, a kind of slide block surface is coated with the method for teflon, on the surface of wherein one side of described slide block 1, offer groove 2, the method for slide block surface coat teflon comprises the steps:

[0028] Step 1: roughen the surface of the slider 1 to increase the surface roughness and increase the surface adhesion of the slider, so that the Teflon coating can be better combined with the surface of the slider. Sandblasting is used to increase the surface roughness of the slider.

[0029] Step 2: Clean the slider 1 with a weak acidic solution to remove surface oil, rust, etc., so as to prevent the dirt from affecting the bonding effect between the Teflon and the slider. If ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com