Operating room disinfectant and preparation method

A disinfectant and operating room technology, applied in the field of operating room disinfectant and preparation, can solve the problems of not having the effect of human health care, easy damage to the skin of the operating personnel, incomplete disinfection, etc., achieving high cost performance, significant effect, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

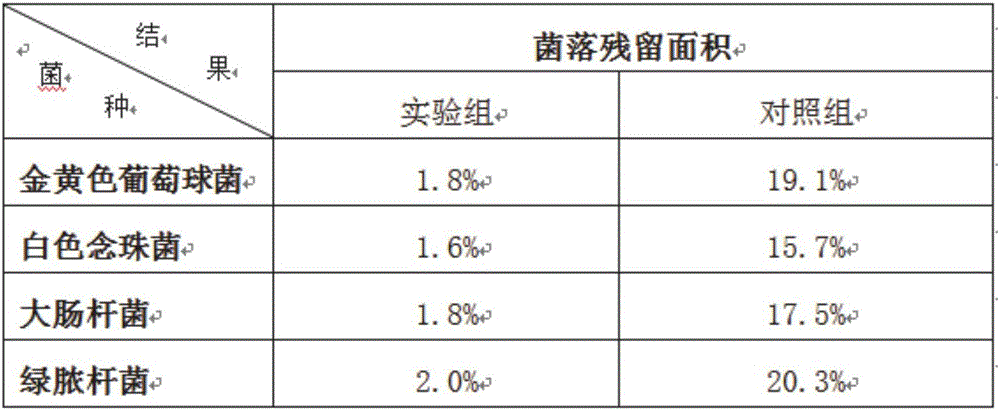

Image

Examples

Embodiment 1

[0034] The composition and weight of the raw materials of the effective components of the disinfectant of the present invention are: 68g of camphor leaves, 63g of purslane, 58g of chamomile, 53g of Cuiyuncao, 48g of forsythia, 43g of yellow quail, 38g of small flying canopy, 33g of Sijiqing, birch Bark 28g, citrus bark 23g.

[0035] The preparation method of disinfectant of the present invention comprises the following processing steps:

[0036] (1) Remove impurities from camphor tree leaves and yellow quail vegetables, wash, chop, add 5 times the amount of ethanol with a volume concentration of 70% and soak for 3 days, stir 3 times a day, take out, filter to obtain the filtrate, and set aside;

[0037] (2) Remove impurities from purslane, chaifengchai, Cuiyuncao, forsythia, and small flying canopy, wash them, put them in a pot, add ionized water to soak for 2 hours, then add 6 times the amount of distilled water, and simmer For 2 hours, extract the decoction; add 4 times the...

Embodiment 2

[0042] The composition and the weight of the raw materials of the effective components of the disinfectant of the present invention are: 63 parts of camphor leaves, 58 parts of purslane, 52 parts of chamomile, 47 parts of Cuiyuncao, 42 parts of forsythia, 37 parts of yellow quail, 33 parts of small flying canopy 28 parts of Sijiqing, 22 parts of birch bark, and 18 parts of oil orange bark.

[0043] The disinfectant preparation method process step of the present embodiment is identical with embodiment 1.

Embodiment 3

[0045] The composition and weight of the raw materials of the effective components of the disinfectant of the present invention are: 56g of camphor leaves, 51g of purslane, 46g of chamomile, 40g of Cuiyuncao, 35g of forsythia, 31g of yellow quail, 26g of small flying canopy, 21g of Sijiqing, birch Bark 16g, citrus bark 11g.

[0046] The disinfectant preparation method process step of the present embodiment is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com