A method for simultaneous detection of carboxymethyllysine and carboxyethyllysine in green tea

A technology of carboxymethyllysine and carboxyethyllysine, which is applied in the field of analysis and detection, can solve problems affecting the applicability of the method, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

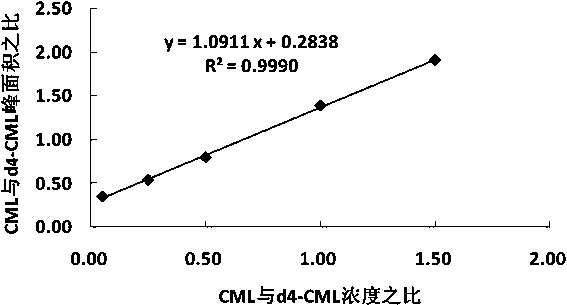

Image

Examples

Embodiment 1

[0034] (1) Extraction: Weigh 50 mg tea powder sample into a 10 mL centrifuge tube, add 2 mL of n-hexane, shake vigorously for 3 min, then centrifuge at 10,000 rpm for 5 min, discard the solvent, and repeat the above steps twice. After degreasing with n-hexane, the sample was blown dry with nitrogen until it recovered to a powder state. Add 1mL Na to the sample 2 B 4 o 7 Buffer (0.2mol / L) and 0.5mL NaBH 4 (1mol / L, prepared with 0.1mol / L NaOH), adjust pH=9.2, and reduce at 4°C overnight (about 8h). Next, add 1 mL of chloroform / methanol (2:1, v / v), centrifuge at 10,000 rpm for 10 min, discard the supernatant; add 5 mL of HCI (6 mol / L) to the obtained precipitate, and place it in an oven at 110 ° C , Hydrolyzed for 12h. After the hydrolysis was completed, the hydrolyzed sample was taken out and cooled to room temperature (25°C), and the volume was adjusted to 10 mL with ultrapure water, then filtered with qualitative filter paper and the filtrate was collected.

[0035] (2) ...

Embodiment 2

[0044] (1) Extraction: Weigh 50 mg of tea powder (same as in Example 1) and place it in a 10 mL centrifuge tube, add 2 mL of n-hexane, vibrate vigorously for 3 min, then centrifuge at 5000 rpm for 10 min, discard the solvent, and repeat the above steps 3 times. After degreasing with n-hexane, the sample was blown dry with nitrogen until it recovered to a powder state. Add 1mL Na to the sample 2 B 4 o 7 Buffer (0.1mol / L) and 0.5mL NaBH 4 (0.8mol / L, prepared with 0.1mol / L NaOH), adjust pH=8.5, and reduce at 4°C for 10h. Next, add 1 mL of chloroform / methanol (1:1, v / v), centrifuge at 5000 rpm for 10 min, discard the supernatant; add 5 mL of HCI (4 mol / L) to the obtained precipitate, and place in an oven at 100 ° C , Hydrolyzed for 30h. After the hydrolysis was completed, the hydrolyzed sample was taken out and cooled to room temperature (25°C), and the volume was adjusted to 10 mL with ultrapure water, then filtered with qualitative filter paper and the filtrate was collecte...

Embodiment 3

[0054] (1) Extraction: Weigh 50 mg of tea powder (same as in Example 1) and place it in a 10 mL centrifuge tube, add 2 mL of n-hexane, vibrate vigorously for 3 min, then centrifuge at 12000 rpm for 4 min, discard the solvent, and repeat the above steps twice. After degreasing with n-hexane, the sample was blown dry with nitrogen until it recovered to a powder state. Add 1mL Na to the sample 2 B 4 o 7 Buffer (0.3mol / L) and 0.5mL NaBH 4 (1.2mol / L, prepared with 0.1mol / L NaOH), adjust pH=10, and reduce at 6°C for 2h. Next, add 1 mL of chloroform / methanol (3:1, v / v), centrifuge at 12000 rpm for 4 min, discard the supernatant; add 5 mL of HCI (8 mol / L) to the obtained precipitate, and place in an oven at 120 ° C , Hydrolyzed for 12h. After the hydrolysis was completed, the hydrolyzed sample was taken out and cooled to room temperature (25°C), and the volume was adjusted to 10 mL with ultrapure water, then filtered with qualitative filter paper and the filtrate was collected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com