A casing heat transfer tube

A technology of heat transfer tube and casing type, which is applied in the field of heat transfer tubes. It can solve the problems of affecting the heat transfer effect, the difficulty of liquid flowing down, and the insufficient liquid supply of the heat transfer tube, so as to achieve long-distance heat transfer and improve heat transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

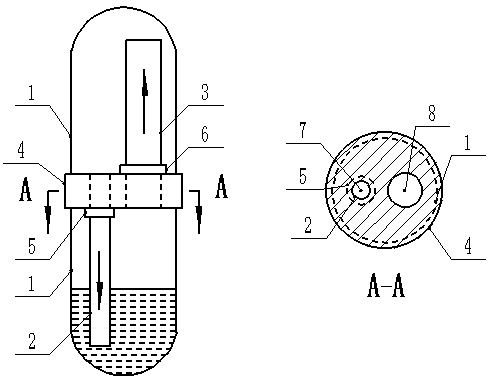

[0013] figure 1 Shown is a sleeve-type heat transfer tube, including two open heat pipes (1), a liquid catheter (2), an air pipe (3), a perforated partition (4), a connecting joint (5), The connection joint 2 (6) organically connects the above components into a whole, vacuumizes the inside of the tube and injects heat transfer working medium to form a sleeve-type heat transfer tube.

[0014] The manufacturing process of the sleeve type heat transfer tube proposed by the present invention is: two through holes are opened on the perforated partition (4), the through hole for the liquid guide tube (7) and the through hole for the air guide tube (8), and the liquid guide tube The diameter of the tube through hole (7) is smaller than the air guide tube through hole (8) to meet the requirement that the gas flow rate is greater than the liquid flow rate; connect the catheter tube (2) to the catheter tube through hole (7) through the connection joint one (5) ), connect the air guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com