High-efficiency compact heat exchanger with vertical cross microchannel

A micro-channel, compact technology, applied in the field of heat exchange, to achieve the effect of small size, good economy and high heat exchange power of heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

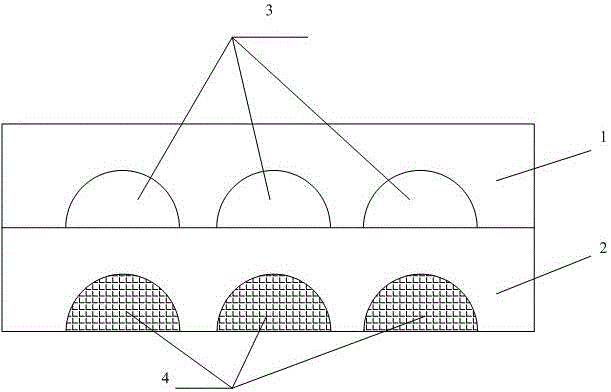

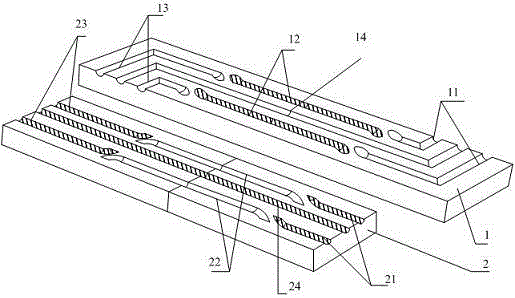

[0028] like Figure 1-Figure 3 Shown: vertical cross microchannel high-efficiency compact heat exchanger, including at least 2 stacked flow plates, the two adjacent flow plates are respectively upper flow plate 1 and lower flow plate 2, and at least 2 fluid channels, upper flow plate 1 and the downstream plate 2 are provided with heat exchange channels, the heat exchange channel of the upper plate 1 includes at least one first-type flow channel, the first-type flow channel includes the first-type flow channel inlet section 11, the first-type The middle section of the flow channel 12, the outlet section of the first type of flow channel 13, the heat exchange flow channel of the lower flow plate 2 includes at least one second type of flow channel, the second type of flow channel includes the inlet section of the second type of flow channel The intermediate section 22 of the type flow channel, the outlet section 23 of the second type flow channel, the inlet section 11 of the firs...

Embodiment 2

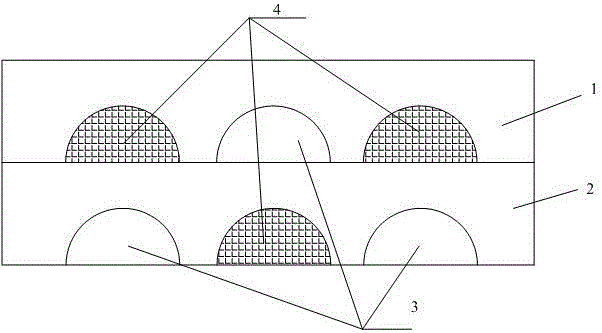

[0032] like figure 2 , image 3 Shown:

[0033] The heat exchange channels of the upper flow plate 1 include two first-type flow channels and one third-type flow channel 14, and the heat exchange channels of the lower flow plate 2 include two second-type flow channels and one fourth-type flow channel twenty four. The first type of flow channel includes the first type of flow channel inlet section 11, the first type of flow channel middle section 12, the first type of flow channel outlet section 13, and the second type of flow channel includes the second type of flow channel inlet section 21, the second type of flow channel The intermediate section 22 of the type flow channel, the outlet section 23 of the second type flow channel, the inlet section 11 of the first type flow channel communicates with the outlet section 13 of the first type flow channel through the middle section 22 of the second type flow channel, The section 21 communicates with the outlet section 23 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com