pcb plating line

A technology of electroplating lines and electroplating tanks, which is applied in the direction of circuits, electrolytic components, electrolytic processes, etc., can solve the problems of inability to monitor vibration motors in real time, shorten the service life of pump motors, and unfavorable use of vibration motors, so as to facilitate adjustment and reference, The effect of reducing labor costs and ensuring the quality of electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

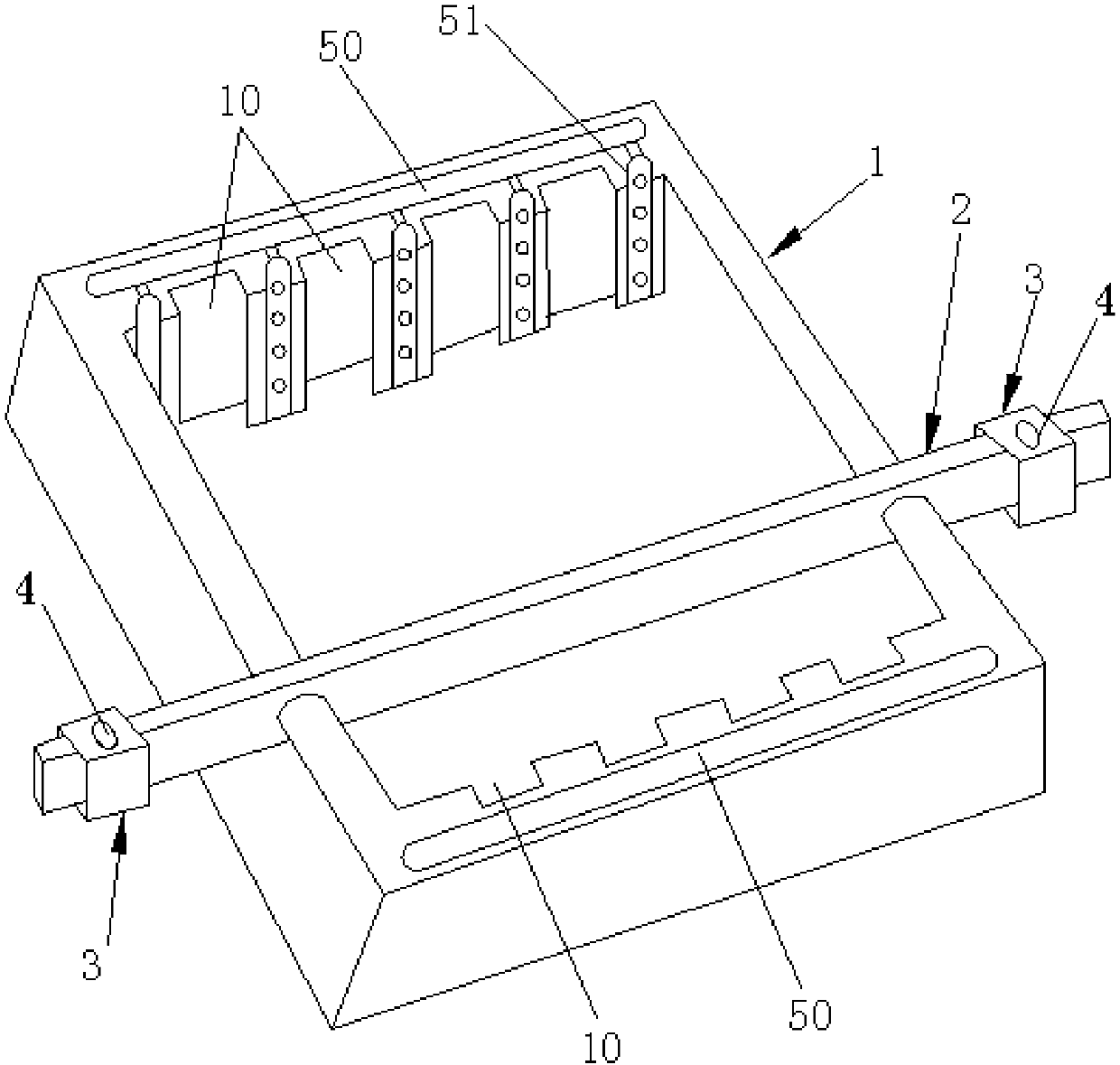

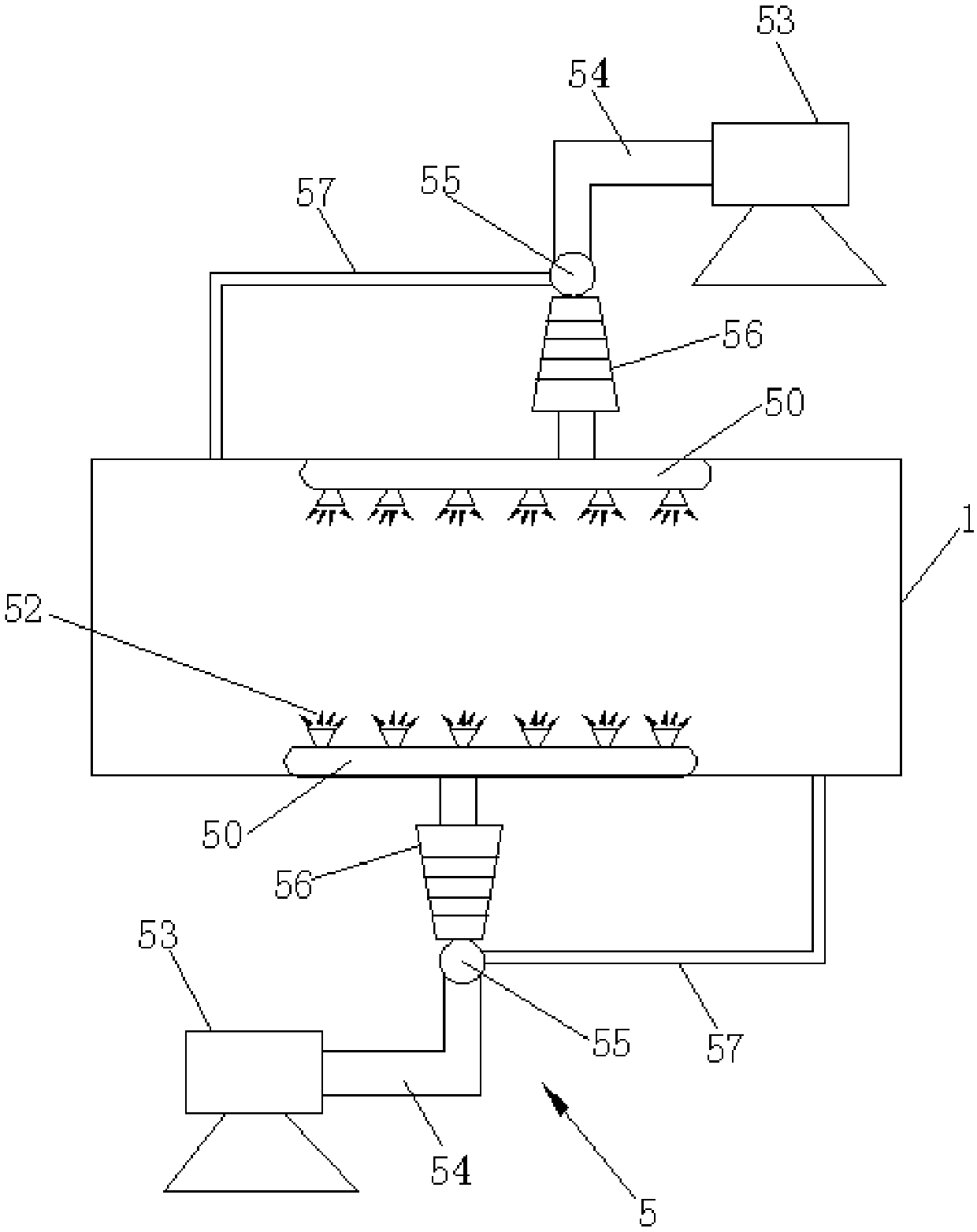

[0029] Please refer to the attached figure 1 As shown, it is a schematic diagram of the partial structure of the PCB electroplating line of the present invention. The PCB electroplating line includes an electroplating tank 1 for holding an electroplating solution, several flying targets 2 and several copper plates (not shown in the figure), and the electroplating tank 1 has a tank bottom and a wall around the bottom of the tank Two pairs of side walls, and a pair of side walls arranged opposite to each other on the electroplating tank 1 are symmetrically provided with a number of fixed bases arranged at intervals, and the number of flying targets 2 are all electrically connected to the negative pole of the power supply, and Each of the flying targets 2 is erected respectively between the two symmetrical fixed bases, and each of the flying targets 2 is also hung with clamps for clamping the PCB board to be plated; the several The copper plates are all electrically connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com