Aluminium-zirconium alloy and powder metallurgic forming method thereof

An aluminum-zirconium alloy and powder metallurgy technology, which is applied in the field of aluminum alloy forming, can solve the problems of uneven composition, insufficient dissolution, and uneven distribution of intermediate alloy ingots, so as to reduce gas inclusions, ensure purity, and be easy to degas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An aluminum-zirconium alloy contains 75% aluminum and 25% zirconium by weight.

[0032] The aluminum-zirconium alloy powder metallurgy forming method comprises the following steps:

[0033] 1) Preparation of raw materials, auxiliary materials, tooling and equipment

[0034] ① Raw materials are prepared according to the following parts by weight: 75 parts of aluminum ingots with a purity of not less than 99.95%, 77.9 parts of potassium fluozirconate;

[0035] ② Prepare the following auxiliary materials: high-purity argon 5 for gas atomization;

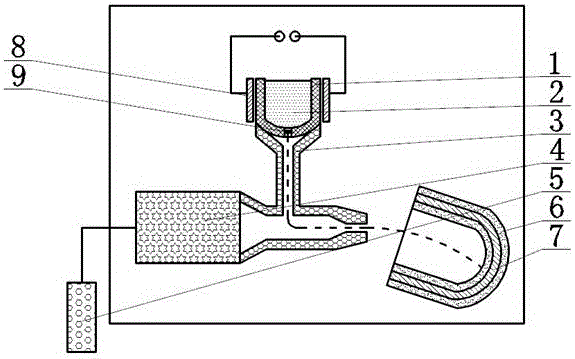

[0036] ③ Prepare the following tooling: a copper crucible 6, which is provided with a circulating water channel 7; an atomization tool 3, which is made of ceramic materials; a graphite crucible 1, which is a lower outlet crucible, and the lower outlet is provided with a Outlet valve 9; mold, the mold is made of stainless steel;

[0037] ④ Prepare the following equipment: vacuum induction melting furnace, which is equipped with...

Embodiment 2

[0054] An aluminum-zirconium alloy contains 70% aluminum and 30% zirconium by weight.

[0055] The aluminum-zirconium alloy powder metallurgy forming method comprises the following steps:

[0056] 1) Preparation of raw materials, auxiliary materials, tooling and equipment

[0057] ① Raw materials are prepared according to the following parts by weight: 70 parts of aluminum ingots with a purity of not less than 99.95%, 93.4 parts of potassium fluozirconate;

[0058] ② Prepare the following auxiliary materials: high-purity argon 5 for gas atomization;

[0059] ③ Prepare the following tooling: a copper crucible 6, which is provided with a circulating water channel 7; an atomization tool 3, which is made of ceramic materials; a graphite crucible 1, which is a lower outlet crucible, and the lower outlet is provided with a Outlet valve 9; mold, the mold is made of stainless steel;

[0060] ④ Prepare the following equipment: vacuum induction melting furnace, which is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com