Graphene composite material and preparation method thereof

A composite material and graphene technology, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of uneven preparation materials, cumbersome preparation methods, and cumbersome preparation methods of graphene, so as to avoid the phenomenon of graphene agglomeration and improve the synthesis process. Simple, favorable insertion and extraction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. Graphene Composite 1

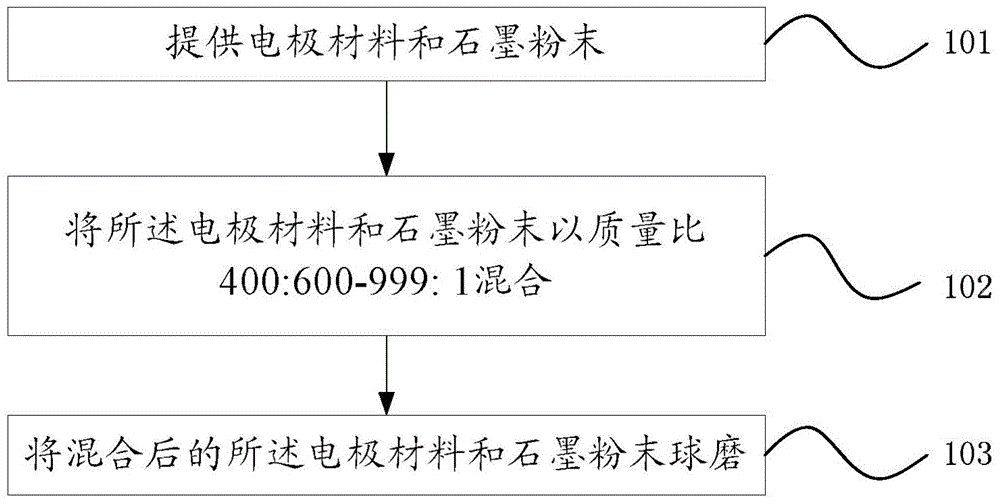

[0035] as attached figure 1 As shown, Embodiment 1 of the present invention provides a method for preparing a graphene composite material, which specifically includes the following steps:

[0036] (101), provide electrode material and graphite powder;

[0037] (102), mixing the electrode material and the graphite powder in a mass ratio of 400:600-999:1;

[0038] (103) Ball milling the mixed electrode material and graphite powder.

[0039] Concretely, 50 parts of titanium oxides and 50 parts of graphite powders that are composed of oligolayer graphene synthetic raw materials are mixed, and after mixing under the inert atmosphere of 1MPa, the pressure is added into the stainless steel ball mill and ball milled, wherein the ball-to-material ratio is 20: 1. Therefore, 2000 parts of stainless steel balls need to be added, and the stainless steel ball-milling tank is ball-milled for 20 hours at a rotating speed of 100 rpm / min. Finally, t...

Embodiment 2

[0040] Example 2. Graphene Composite 2

[0041] Embodiment 2 of the present invention also provides a method for preparing a graphene composite material, and the preparation steps are the same as those in Embodiment 1, except that 40 parts of titanium oxide and 60 parts of graphite powder whose composition is a raw material for synthesizing few-layer graphene are mixed, After mixing under an inert atmosphere with a pressure of 2MPa, add it to a stainless steel ball mill for ball milling, wherein the ratio of ball to material is 20:1, so 2000 parts of stainless steel balls need to be added, and the stainless steel ball mill is ball-milled at a rotational speed of 200rpm / min After 50 hours, the ball-milled product finally obtained is the graphene composite material 2, that is, the electrode material having 2-10 layers of graphene coating. The steps described above were performed in a glove box.

Embodiment 3

[0042] Example 3. Graphene Composite 3

[0043] Embodiment 3 of the present invention also provides a method for preparing a graphene composite material, and the preparation steps are the same as those in Embodiment 1, except that 90 parts of lithium manganate and 10 parts of graphite powder whose composition is a raw material for oligolayer graphene are mixed , after mixing in an inert atmosphere with a pressure of 1.5MPa, add it to a stainless steel ball mill tank for ball milling, wherein the ball-to-material ratio is 20:1, so 2000 parts of stainless steel balls need to be added, and the stainless steel ball mill tank is rotated at 150rpm / min. The ball-milling is performed for 100 hours, and the finally obtained product after ball-milling is the graphene composite material 3, that is, an electrode material having 2-10 layers of graphene coating. The steps described above were performed in a glove box.

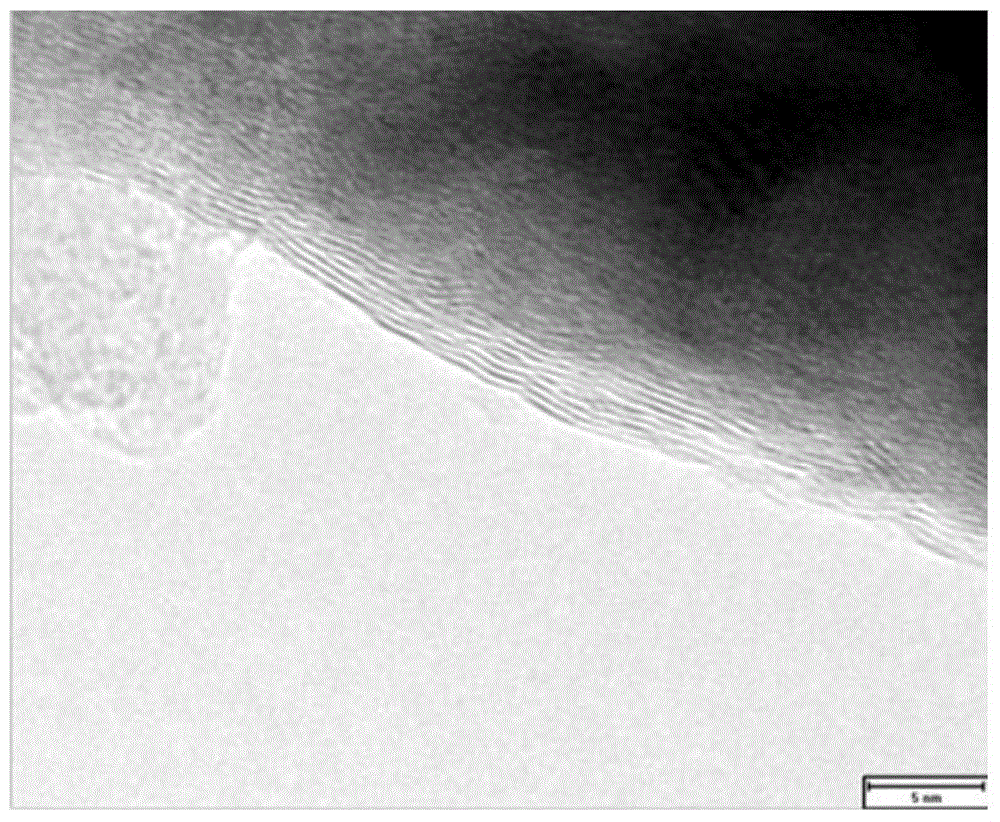

[0044] attached by figure 2 As shown, it is the electron microscope ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com