Flame-retardant and antibacterial polyurethane waterproof coating for high-speed rail

A polyurethane waterproof and coating technology, applied in the field of coatings, can solve the problems of reducing the load-bearing area of steel bars, aggravating the freeze-thaw damage of concrete, reducing the utilization rate of bridge steel bars, etc., achieving low cost, excellent mechanical properties, and simple and stable construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

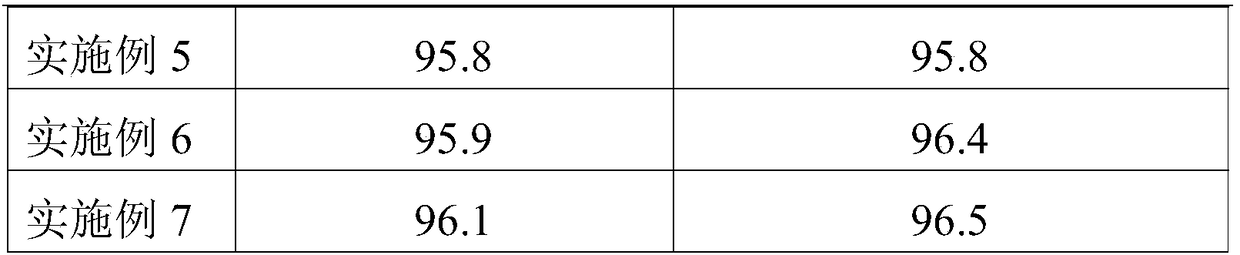

Examples

Embodiment 1

[0036] Flame retardant and antibacterial polyurethane waterproof coating materials for high-speed rail (parts by weight): 15 parts of polyether HPOP40, 35 parts of polyether EP-330N (G), 14 parts of 1,6-hexamethylene diisocyanate, 0.6 parts of dioctyl adipate, 16 parts of xylene, 15 parts of chlorinated polyethylene, 18 parts of silicon powder, 10 parts of talcum powder, 6 parts of 1,1,1-trimethylolpropane, 0.45 parts of stannous octoate, 3 parts of inorganic antibacterial agent, flame retardant 1.5 parts.

[0037] The inorganic antibacterial agent is obtained by uniformly stirring and mixing silver chloride, silver tungstate and zinc carbonate in a mass ratio of 1:1:1.

[0038] The flame retardant is obtained by uniformly stirring and mixing triphenyl phosphate, hexabromocyclododecane, and dimethyl methyl phosphate in a mass ratio of 1:1:1.

[0039] Preparation of flame retardant and antibacterial polyurethane waterproof coating for high-speed rail:

[0040] (1) Add polyeth...

Embodiment 2

[0044] It is basically the same as in Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing uniformly silver tungstate and zinc carbonate at a mass ratio of 1:1. Obtain the flame-retardant and antibacterial polyurethane waterproof coating for high-speed rail of embodiment 2.

Embodiment 3

[0046] It is basically the same as in Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing uniformly silver chloride and zinc carbonate at a mass ratio of 1:1. Obtain the flame-retardant and antibacterial polyurethane waterproof coating for high-speed rail of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com