Wear-resistant PVC (polyvinyl chloride) plastic and preparation method

A wear-resistant and plastic technology, applied in the field of wear-resistant PVC plastic and its preparation, can solve the problems of easy aging and poor thermal stability, and achieve the effects of low cost, long service life, simple and stable construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

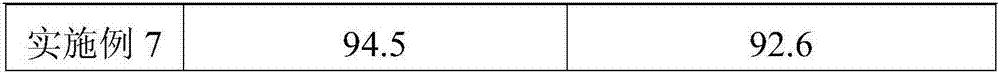

Examples

Embodiment 1

[0030] Wear-resistant PVC plastic raw materials (parts by weight): 100 parts of polyvinyl chloride resin, 1.5 parts of dioctyl adipate, 1.5 parts of polyethylene wax, 3 parts of silicon powder, 0.3 parts of vinyltrimethoxysilane, and 0.03 parts of antibacterial agent , 0.06 part of heat stabilizer.

[0031] The antibacterial agent is composed of cocamidopropyl betaine, 2-butyl-1,2-benzisothiazoline-3-one, 5-chloro-2-methyl-4-isothiazoline-3- The ketone is obtained by stirring and mixing uniformly according to the mass ratio of 1:1:1.

[0032] The heat stabilizer is obtained by uniformly stirring and mixing zinc 2-ethylhexanoate, zinc laurate and zinc stearate in a mass ratio of 1:1:1.

[0033] Preparation of abrasion resistant PVC plastic:

[0034] (1) take each component according to weight ratio;

[0035] (2) Add each component into a high-speed mixer for mixing, the mixing speed is 86 rpm, and the stirring time is 13 minutes;

[0036] (3) Place the mixed material in a t...

Embodiment 2

[0038] Basically the same as Example 1, the only difference is that the antibacterial agent consists of 2-butyl-1,2-benzisothiazolin-3-ketone, 5-chloro-2-methyl-4-isothiazoline -3-ketone is obtained by stirring and mixing at a mass ratio of 1:1. Obtain the wear-resistant PVC plastic of embodiment 2.

Embodiment 3

[0040] Substantially the same as Example 1, the only difference is that the antibacterial agent consists of cocamidopropyl betaine, 5-chloro-2-methyl-4-isothiazolin-3-one in a mass ratio of 1:1 Stir to mix well. Obtain the wear-resistant PVC plastic of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com